iii

Important Safety Instructions

Before applying power to the system, verify that your product is configured properly for your

particular application.

WARNING

Hazardous voltages may be present when covers are removed. Qualified

personnel must use extreme caution when servicing this equipment.

Circuit boards, test points, and output voltages also may be floating above

(below) chassis ground.

WARNING

The equipment used contains ESD sensitive ports. When installing

equipment, follow ESD Safety Procedures. Electrostatic discharges might

cause damage to the equipment.

Only

qualified personnel

who deal with attendant hazards in power supplies, are allowed to perform

installation and servicing.

Ensure that the AC power line ground is connected properly to the Power Rack input connector or

chassis. Similarly, other power ground lines including those to application and maintenance

equipment

must

be grounded properly for both personnel and equipment safety.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any

cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis.

Howeve

r, depending on the user’s application configuration,

HIGH VOLTAGES HAZARDOUS TO

HUMAN SAFETY

may be normally generated on the output terminals. The customer/user must

ensure that the output power lines are labeled properly as to the safety hazards and that any

inadvertent contact with hazardous voltages is eliminated.

Guard against risks of electrical shock during open cover checks by not touching any portion of the

electrical circuits. Even when power is off, capacitors may retain an electrical charge. Use safety

glasses during open cover checks to avoid personal injury by any sudden component failure.

Neither AMETEK Programmable Power Inc., San Diego, California, USA, nor any of the subsidiary

sales organizations can accept any responsibility for personnel, material or inconsequential injury,

loss or damage that results from improper use of the equipment and accessories.

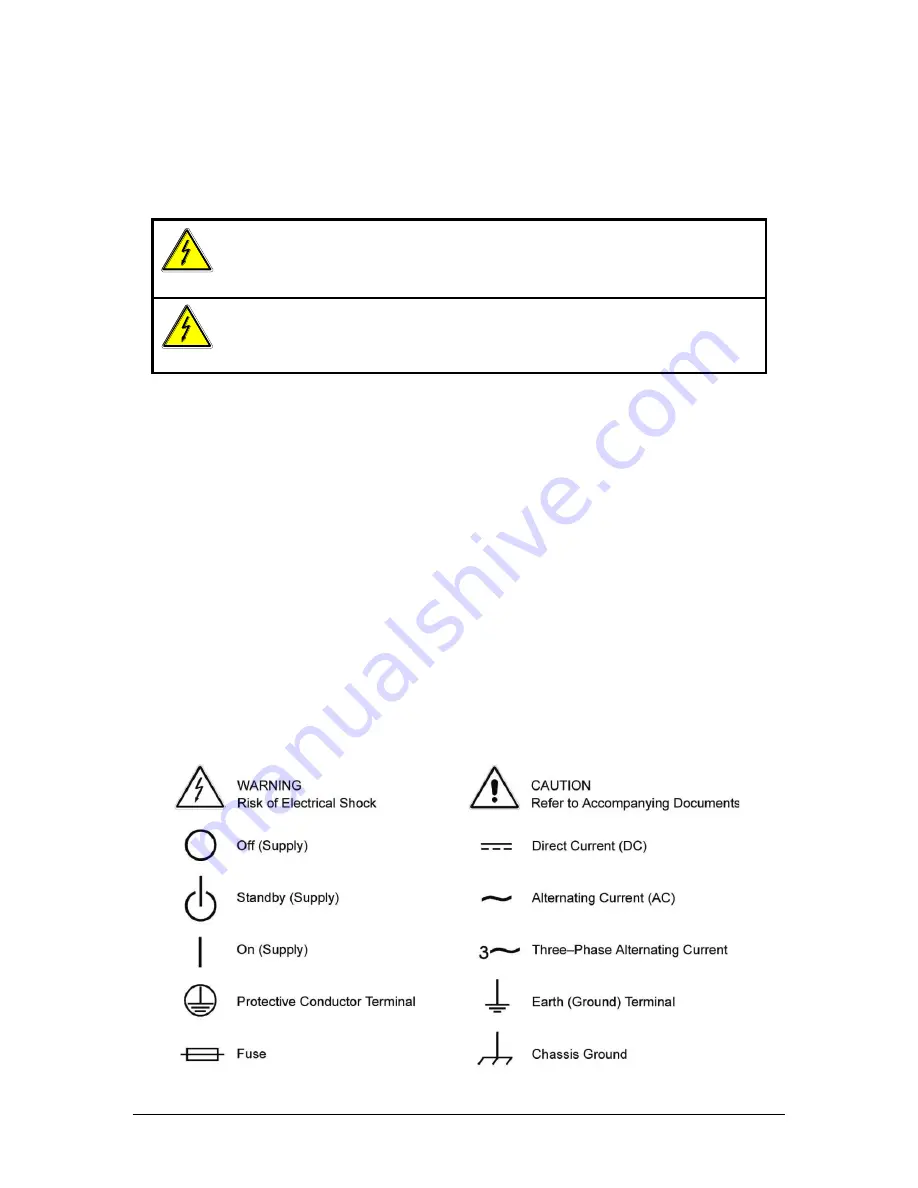

SAFETY SYMBOLS

Summary of Contents for 10001i

Page 2: ......

Page 3: ......

Page 6: ...ii This page intentionally left blank...

Page 38: ...User Manual 24 i Series iX Series Figure 3 5 Rear Panel View for the 3001i 3001iX...

Page 39: ...User Manual i Series iX Series 25 Figure 3 6 Rear Panel View for the 5001i 5001iX...

Page 43: ...User Manual i Series iX Series 29 Figure 3 8 Functional Test Setup...

Page 44: ...User Manual 30 i Series iX Series Figure 3 9 Single Phase 10000 VA System 10001iX i...

Page 46: ...User Manual 32 i Series iX Series Figure 3 11 Single Phase 15000 VA System 15001iX i...

Page 48: ...User Manual 34 i Series iX Series Figure 3 13 Connection With MODE Option...

Page 118: ...User Manual 104 i Series iX Series Figure 5 2 Power Source Module Block Diagram...

Page 121: ...User Manual i Series iX Series 107 Figure 5 3 5001i Internal Layout...

Page 122: ...User Manual 108 i Series iX Series Figure 5 4 Logic Board LED s...

Page 124: ...User Manual 110 i Series iX Series Figure 5 5 AC Power Stage Layout...

Page 125: ...User Manual i Series iX Series 111 Figure 5 6 AC Control Logic Block Diagram...

Page 138: ...User Manual 124 i Series iX Series Figure 6 3 Adjustment Location...

Page 152: ...User Manual 138 i Series iX Series Figure 9 4 Voltage Modulation...

Page 219: ...User Manual i Series iX Series 205 Figure 9 36 Example Connection With 5001iX and EOS 1...

Page 221: ...User Manual i Series iX Series 207 Figure 9 38 15003iX CTS EOS3 LR3...

Page 222: ...User Manual 208 i Series iX Series Figure 9 39 15003iX 3 EOS3...

Page 233: ...User Manual i Series iX Series 219 Figure 9 41 Example Connection With MODE iX...

Page 240: ...User Manual 226 i Series iX Series Figure 9 42 Example Connections With OMNI 1 18i...

Page 241: ...User Manual i Series iX Series 227 Figure 9 43 Example Connections With OMNI 3 18i...