SXRXLXX1 - SIL IntelliPoint RF Series User's Manual

22

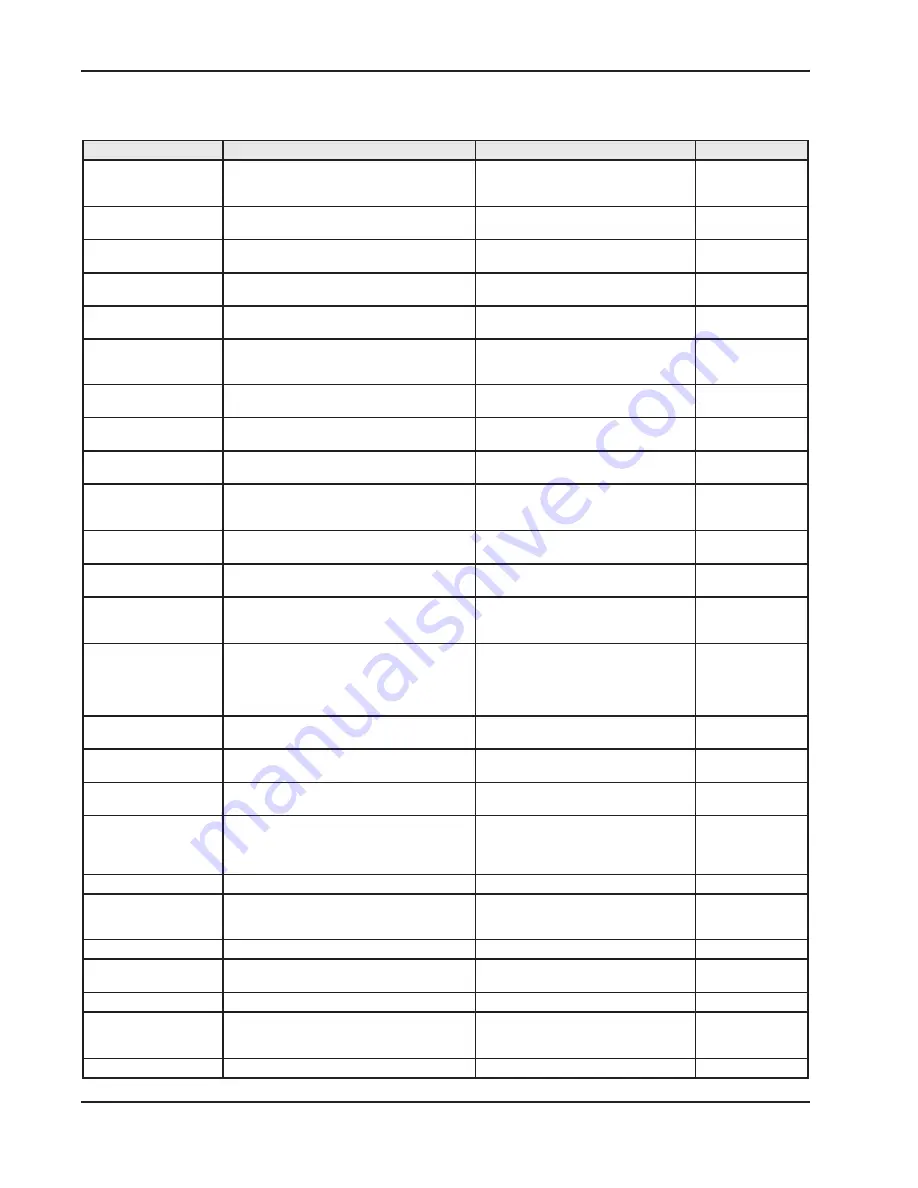

Symptom

Possible Cause

Solution

See Section

Switch is in alarm and will

not clear

Sensor is coated by a conductive material and the

Cote-Shield™ element does not extend far enough

into the vessel

Need a sensor with a longer Cote-Shield

element. Rule of thumb is nozzle

expected wall c 2 inches.

Section 2.2, 4.5

Fail Safe switch is set to the wrong setting

Check to make sure the fail safe switch is in

the correct position

Section 2.6.3

Active section of sensor is touching an internal

structure or material is bridging active to ground.

May be able to shorten sensor (consult

factory) or relocate sensor.

Appendix A

Section 2.2, 4.5

Connection cable or harness between unit and

sensor is damaged

Check connection cable for shorts, opens, or

damage and proper termination

Section 4.7, 4.6

Flexible sensor is swaying and active is touching

vessel or structure

Add 1 or 2 seconds of reverse acting time

delay.

Section 2.6.2

Switch stays in alarm for

extended period after level

falls below sensor

Material bridging from active to tank structure

May be able to shorten sensor (consult

factory) or relocate sensor.

Appendix A

Section 2.2, 4.5

Time delay may be active

Make sure time delay pot is full

counterclockwise.

Section 2.6.2

Switch does not respond to

material

There may not be enough active to detect an

insulating material

Change to high sensitivity or adding active

length to sensor

Consult Factory

Section 4.9, App. A

Switch was calibrated with sensor covered by

material

Make sure material level is below sensor

and re-calibrate

Section 2.6.7

Granular material – Active section is not getting

enough coverage due to angle of repose

Relocate sensor to get more coverage or

lengthen active. Changing to high sensitivity

may also help.

Appendix A

Connection cable or harness between unit and

sensor is damaged

Check connection cable for shorts, opens, or

damage and proper termination

Section 4.6, 4.7

Switch delays in

responding to material

Reverse acting time delay may be active

Check time delay settings to make sure they

are correct

Section 2.6.2

LED’s are Flashing

Flashing LED’s indicate one of three things.

Over Range / Under Range / fault

Consult instruction manual to determine

which of the three symptoms are

experienced.

Section 4.3, 4.4, 2.7

Over Range indicates that

the standing capacitance of

the sensing element in the

vessel is to large to allow

calibration

A long sensing element may generate too much

standing capacitance to calibrate

Additional capacitance must be added to the

calibration range (padding)

Section 4.9

Consult Factory

The sensor could be touching an internal tank

structure

May be able to shorten sensor (consult

factory) or relocate sensor.

Appendix A

Switch was calibrated with sensor covered by

material

Make sure material level is below sensor

and re-calibrate

Section 2.6.7

Improper wiring connection (Remote Switches)

Check remote cable connections to confirm

they are correct.

Section 2.8

Under Range indicates

that the electronic unit

is not seeing enough

capacitance.

Sensing Element is Disconnected

Verify sensing element cable connections.

Test cable continuity.

Section 4.6, 4.7

Unit is damaged

Consult factory

Section 4.9

Fault Indicates the Auto-

Verify feature has detected

a problem.

Sensing Element is Damaged

Check Sensing Element for Damaged

Section 2.6.6

Center wire to shield short

Check cable & sensor

Section 4.5, 4.6, 4.7

Connecting Cable is Damaged

Check connection cable for damage, shorts,

and proper termination

Section 4.6, 4.7

Electronic Unit is damaged

Consult factory

Section 4.9

Green Power LED is out

Electronic unit is not getting power

Check power source to make sure proper

power is supplied and connections are

correct

Section 2.4

Electronic Unit is damaged

Consult factory

Section 4.9

4.1

RF Point Level Troubleshooting Guide

Summary of Contents for SIL IntelliPoint RF S*R*L Series

Page 4: ...Contents...

Page 6: ...Section 1...

Page 38: ...SXRXLXX1 SIL IntelliPoint RF Series User s Manual 32 Section 5...

Page 41: ...Specifications 35 Section 6...

Page 43: ...Control Drawings 37 6 1 FM FMc Control Drawings Continued...

Page 44: ...SXRXLXX1 SIL IntelliPoint RF Series User s Manual 38 6 1 FM FMc Control Drawings Continued...

Page 45: ...Control Drawings 39 6 1 FM FMc Control Drawings Continued...

Page 46: ...SXRXLXX1 SIL IntelliPoint RF Series User s Manual 40 6 1 FM FMc Control Drawings Continued...

Page 47: ...Control Drawings 41 6 1 FM FMc Control Drawings Continued...

Page 48: ...SXRXLXX1 SIL IntelliPoint RF Series User s Manual 42 6 1 FM FMc Control Drawings Continued...

Page 56: ...SXRXLXX1 SIL IntelliPoint RF Series User s Manual 50 6 2 ATEX Control Drawings...

Page 57: ...Control Drawings 51 6 2 ATEX Control Drawings Continued...

Page 66: ...SXRXLXX1 SIL IntelliPoint RF Series User s Manual 60 6 4 IECEx Control Drawings...

Page 67: ...Control Drawings 61 6 4 IECEx Control Drawings Continued...

Page 75: ...Control Drawings 69 6 5 Mounting and Wiring for Spark Protector Drawings...

Page 77: ...Control Drawings 71 6 5 Mounting and Wiring for Spark Protector Continued...

Page 78: ...SXRXLXX1 SIL IntelliPoint RF Series User s Manual 72 6 6 Adding a Padded Capacitor...

Page 79: ...Control Drawings 73 6 6 Adding a Padded Capacitor Continued...

Page 80: ...SXRXLXX1 SIL IntelliPoint RF Series User s Manual 74 6 6 Adding a Padded Capacitor Continued...

Page 81: ...Control Drawings 75 6 7 Dual Seal Assembly for 700 Series Sensing Elements...

Page 82: ...SXRXLXX1 SIL IntelliPoint RF Series User s Manual 76 6 7 Dual Seal Assembly Continued...

Page 83: ...Control Drawings 77 6 7 Dual Seal Assembly Continued...

Page 84: ...Appendix A...

Page 88: ...SXRXLXX1 SIL IntelliPoint RF Series User s Manual A 4 Appendix B...

Page 90: ...SXRXLXX1 SIL IntelliPoint RF Series User s Manual B2 EXIDA Report Results...