1

13

14

25

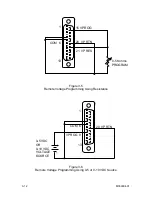

Figure 3-2

Pin-out for Connector J1

The power supply may be configured via

connector J1 on the rear panel for different

operating configurations: local and remote

current programming, local and remote

voltage programming, normal parallel,

auto-parallel, normal series, auto-series,

and auto-tracking. The use and operating

requirements of each configuration are

provided in the following paragraphs.

Reference Table 3-2 for connector J1

designations and functions. See Figure 3-2

for pin-out diagram.

CAUTION:

These control inputs are referenced to the

negative output of the power supply.

Grounding the positive output of the power

supply or biasing the output of the supply

above chassis potential will cause this input

(along with the output of the supply) to

have a potentially hazardous offset voltage.

Exercise caution under these conditions.

3.3 LOCAL

OPERATION

Units are shipped from the factory configured for local voltage/current control and local

voltage sensing. J1 is supplied with a mating connector with remote on/off jumpered for

ON (terminal 5 shorted to terminal 6).

3.4 REMOTE CURRENT PROGRAMMING

The remote current programming is used for applications that require the output current

be programmed (controlled) from a remote source. An external resistance or external

voltage source may be used as a programming device. When using remote current

programming, a shielded, twisted-pair, hookup wire is recommended to prevent noise

interference with programming signals.

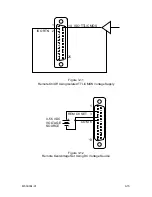

1.

External Current Programming Using Resistance. The resistance coefficient

for remote current programming is 5k ohms/100% rated output with respect

to terminal J1-23 (IP RTN). The programming current from terminal J1-22

(IP RES) is factory set for 1 milliamp. This yields a coefficient of 1.0% of

rated output current for each 50 ohms. If multiple switches or relays are

used to program different levels, make-before-break contacts are

recommended. Note that if an external resistance is used for remote

programming, the current programming return (IP RTN), terminal J1-23,

must be connected directly to or within ±3 volts of the power supply common

terminal, J1-24. See Figure 3-3 for connection requirements.

M550004-01

3-8

Summary of Contents for Sorensen DHP Series

Page 1: ...M550004 01 Rev K www programmablepower com DHP Series DC Power Supplies Operation Manual...

Page 2: ......

Page 3: ......

Page 4: ......

Page 6: ...This page intentionally left blank ii...

Page 8: ...This page intentionally left blank iv...

Page 10: ...This page intentionally left blank WA 2...

Page 44: ...This page intentionally left blank M550004 01 3 16...

Page 54: ...This page intentionally left blank M550004 01 5 6...