TW 5250 • TW 3500 • TW 1750 Installation

Elgar TrueWave 2-15

In high performance applications, as in motor start-up and associated inrush/ transient

currents, additional consideration is required. The cable wire gauge must consider

peak voltages and currents that may be up to ten times the average values. An

underrated wire gauge adds losses that alter the inrush characteristics of the

application and thus the expected performance.

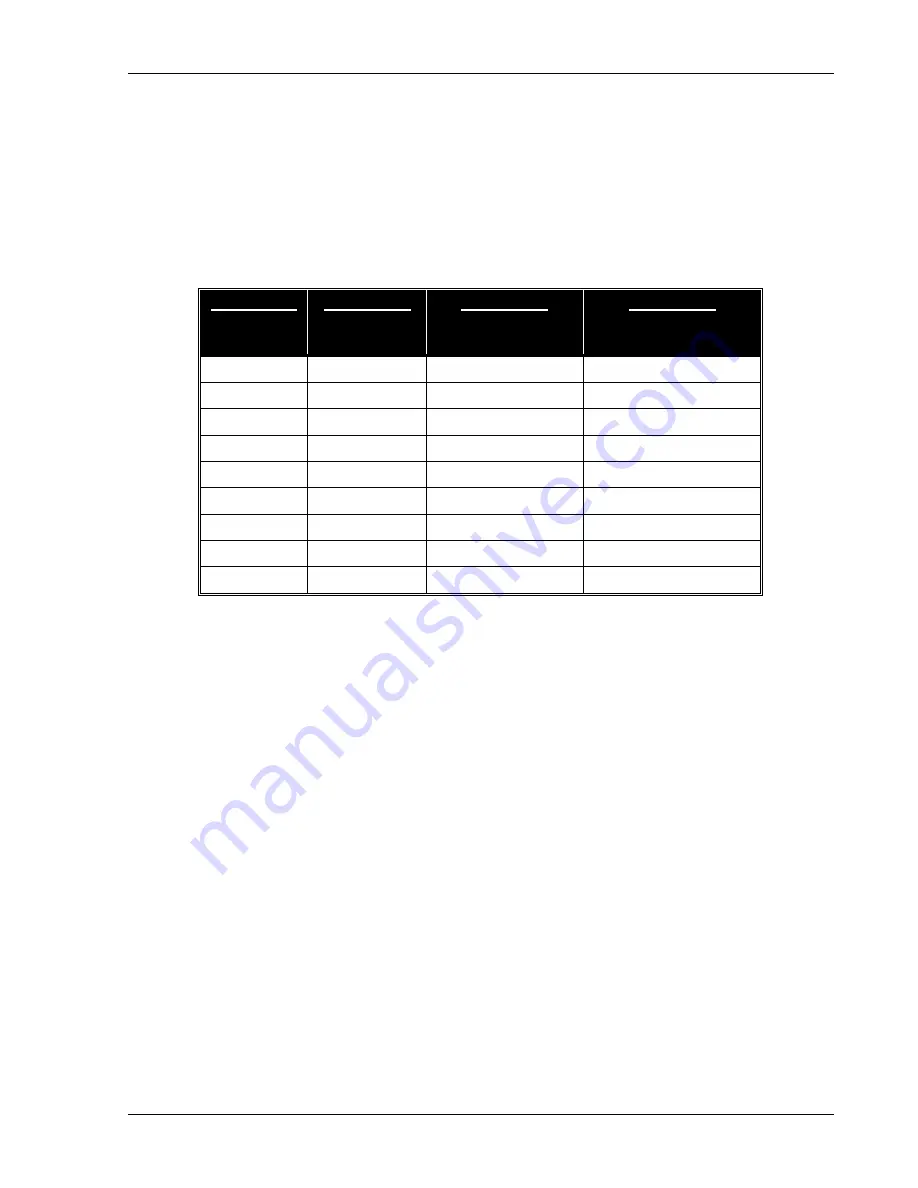

Table 2-8 identifies ratings for popular DC and AC power source cable wire gauges.

C

OLUMN

1:

SIZE

(AWG)

C

OLUMN

2:

AMPERES

(MAXIMUM)

C

OLUMN

3:

OHMS/100 FEET

(ONE WAY)

C

OLUMN

4:

IR DROP/100 FEET

(COL. 2 X COL. 3)

14

15

0.257

3.85

12

20

0.162

3.24

10

30

0.102

3.06

8

40

0.064

2.56

6

55

0.043

2.36

4

70

0.025

1.75

2

95

0.015

1.42

1/0

125

0.010

1.25

3/0

165

0.006

1.04

Table 2-8 Recommended Wire Gauge Selection Guide

The following notes apply to Table 2-8 and to the power cable definition:

1. The above figures are based upon insulated copper conductors at 25°C (77°F),

two current carrying conductors in the cable plus a safety (chassis) ground.

Columns 3 and 4 refer to “one way” ohms and IR drop of current carrying

conductors (e.g., a 50-foot cable contains 100 feet of current carrying

conductor).

2. Determine which wire gauge for the application by knowing the expected peak

load current (I

peak

), the maximum tolerated voltage loss (V

loss

) within the cable,

and the one way cable length.