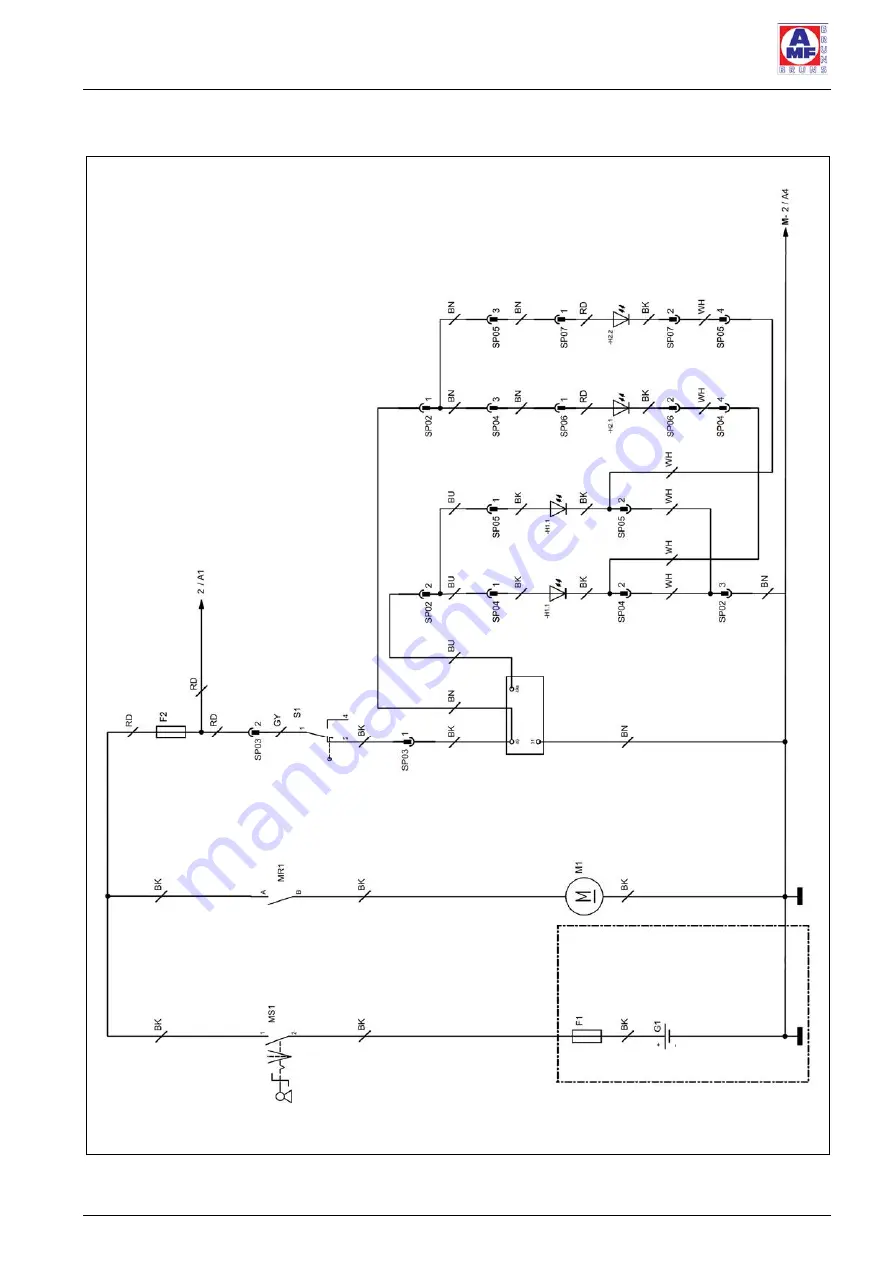

Electrical Circuit Diagrams

Linear Lift AL1

Page 67 of 72

13

Electrical Circuit Diagrams

Figure 34: Electrical Circuit Diagram (1)

Position

indicator

Blinker l

amp

Position

indicator

Blinker l

amp

Blinker r

elay

12V

Micro-swit

ch

Fuse 7.

5 A

DC-motor

12V

Battery i

solatio

n

switch

Vehicle

Fuse 11

0 A

Starter b

attery

12 V

Starter s

witch

Summary of Contents for LINEARLIFT AL1

Page 1: ...Operating Instructions www amf bruns de LINEAR LIFT AL1 ...

Page 2: ......