Summary of Contents for A240

Page 1: ...TWO POST LIFT Model A240 ...

Page 4: ...2 Arm Swings View 2513mm 1270mm 814mm 683mm 1159mm Fig 2 ...

Page 11: ...9 2 Install cables See Fig 14 Fig 14 ...

Page 12: ...10 F Assembly oil hose assy 1 Install oil hose See Fig 15 Fig 15 81 85 81A 81 79A 80 81 81 79 ...

Page 26: ...24 IV EXPLODED VIEW Model A240 Fig 38 Car in direction ...

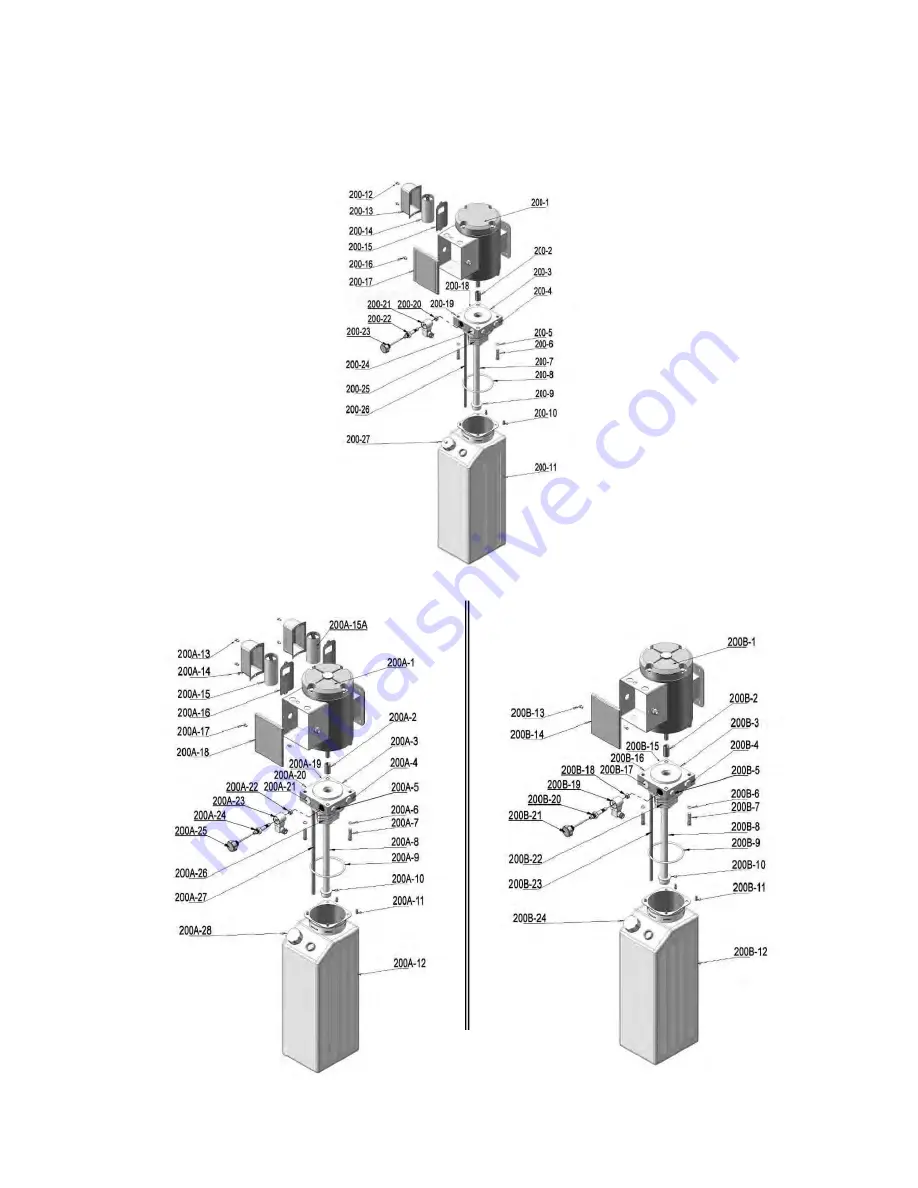

Page 27: ...25 Cylinders Control Box Fig 39 Fig 40 ...

Page 40: ... 38 72225302 01 2014 ...