INSTALLATION

A. B O X IN THE WALL

(MASTER STATUS & AREA ALARMS)

1. Remove the alarm box from the

shipping carton and install the box

securely in the roughed-in wall at the

appropriate place. The mounting brack-

ets are adjustable to suit the thickness

of the wall. Do not remove the

Window

Frame or any Modules from the ship-

ping carton until the box is mounted in

the wall and all the plastering, external

wiring, and brazing of the copper pig-

tails is complete.

(AREA ALARMS ONLY)

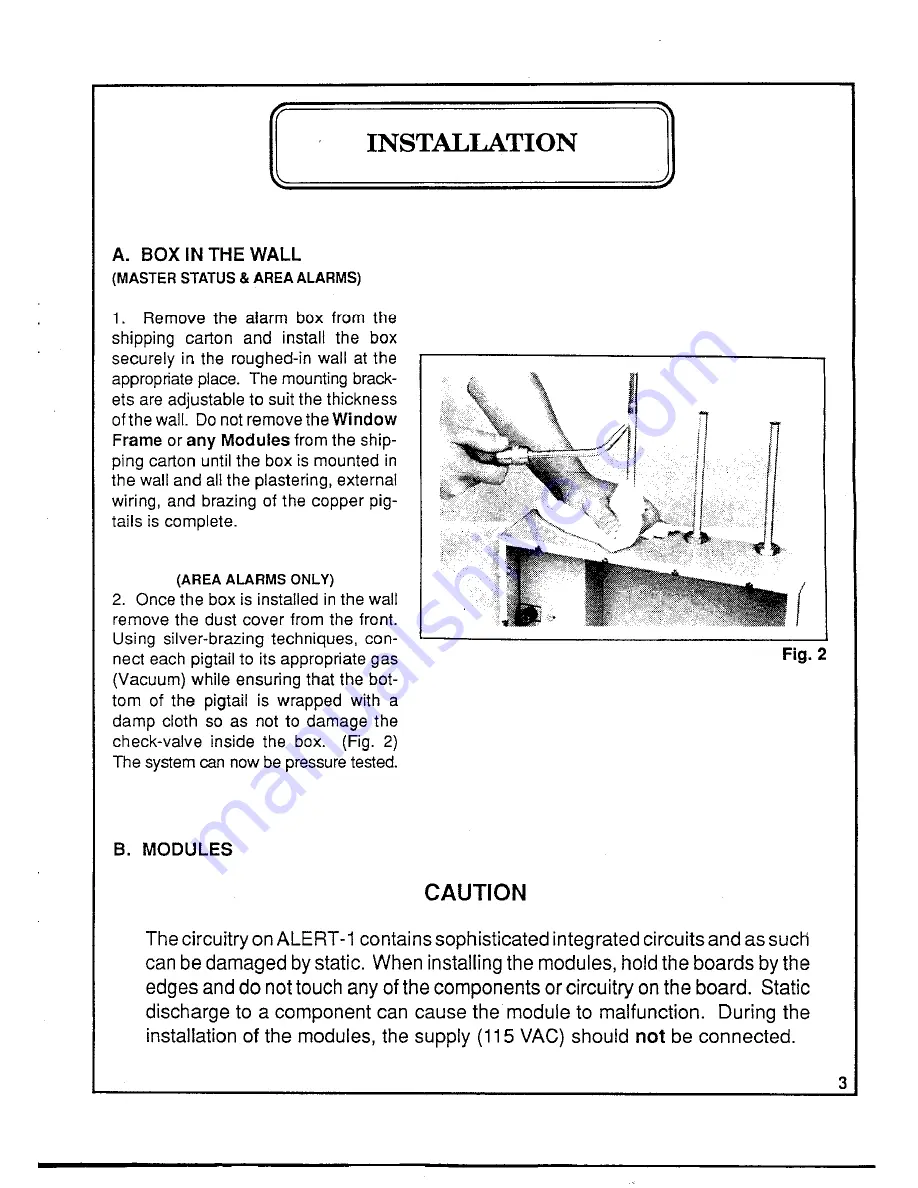

2. Once the box is installed in the wall

remove the dust cover from the front.

Using silver-brazing techniques, con-

nect each pigtail to its appropriate gas

(Vacuum) while ensuring that the bot-

tom of the pigtail is wrapped with a

damp cloth so as not to damage the

check-valve inside the box. (Fig. 2)

The system can now be pressure tested.

B. MODULES

CAUTION

Fig. 2

The circuitry on ALERT-1 contains sophisticated integrated circuits and as such

can be damaged by static. When installing the modules, hold the boards by the

edges and do not touch any of the components or circuitry on the board. Static

discharge to a component can cause the module to malfunction. During the

installation of the modules, the supply (115 VAC) should

not

be connected.

3