10

Amico Corporation

B: LOCAL (inside the back box)

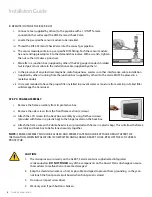

i. The sensor module is provided with a 6”-8” [0.1 m - 0.2 m] #22 gauge stranded,

shielded and twisted pair cable. One wire is red (positive) and the other wire is

black (negative). Connect the wires to the display module as shown in Appendix D.

Take the red wire from the sensor and attach it to terminal “” on the display

module. Take the black wire from the sensor and attach it to terminal “Sensor -”. The

terminal block on the display module is clearly marked for proper connection of the

sensor wires.

ii. Repeat the above procedures with the remaining sensor modules.

C: REMOTE (outside the back box)

i. The sensor module is provided with 6" - 8" [0.1m - 0.2m] #22 gauge stranded, shielded and twisted pair cable.

Connect the wires to a junction box (supplied by others) located near the sensor as per the wiring diagram

(see Appendix E).

ii. Connect a #22 gauge stranded, shielded and twisted pair cable ONLY, up to 1000 ft [304.8 m]. Knockouts are

provided throughout the alarm back box.

iii. Connect the red wire from the cable to the terminal on the display module marked ””. Connect the

black wire to terminal “Sensor -” as shown in the wiring diagram (see Appendix E).

iv. Repeat the above procedures with the remaining sensor modules using the wiring diagram.

NOTE:

• When remote sensors are used, ONLY a #22 gauge stranded, shielded twisted pair cable must be used (BELDEN

#8451 or equivalent, supplied by others).

• Do not ground the shield drain wire at sensor or inside the alarm panel back box

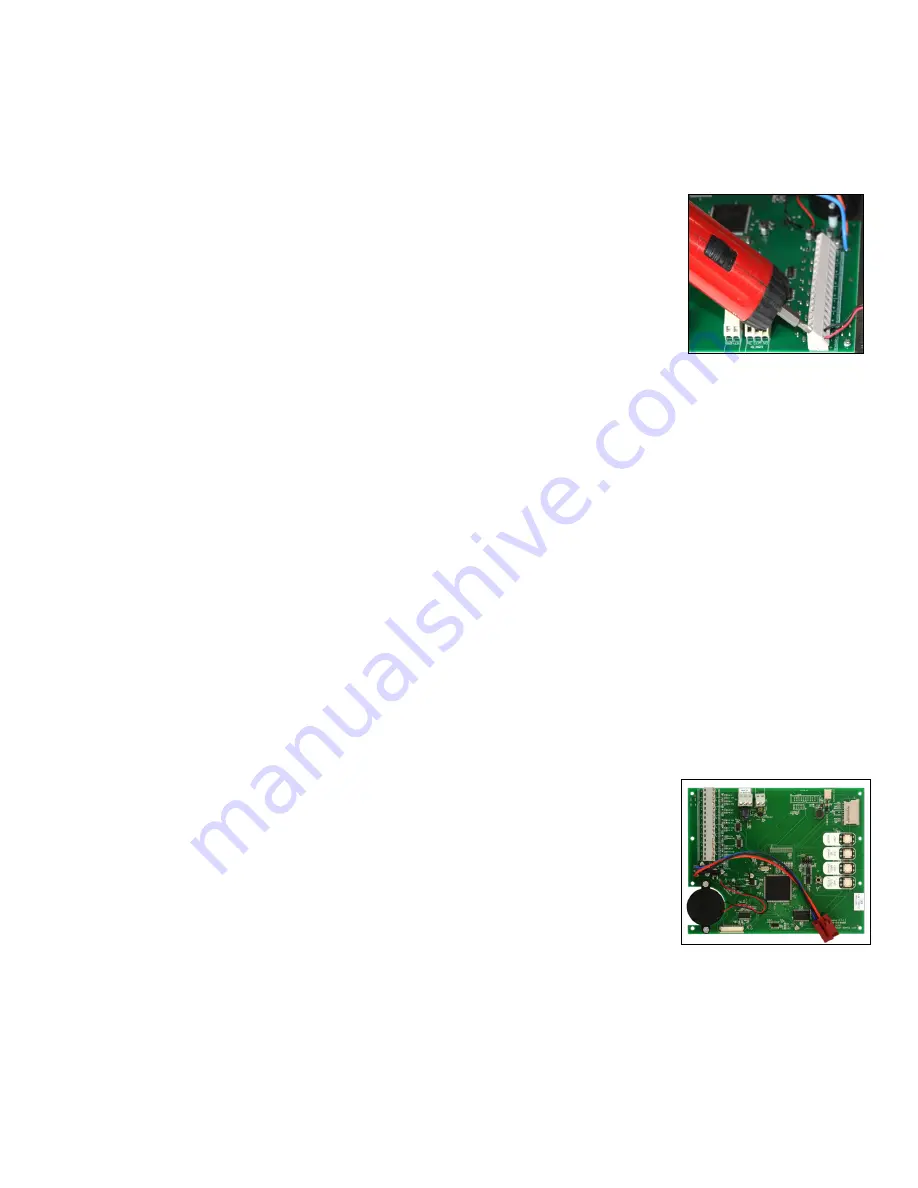

STEP 8: LCD DISPLAY MODULE

If the dry contacts for a generic alarm is to be used for remote monitoring, connect the wires

to the appropriate terminals: COM (Common), NO (Normally Open) or NC (Normally Closed),

using the diagram in

Appendix A

.

See

Appendix G

for contact rating.

Once the sensors are connected and the power has been switched on, use the following

steps to setup the LCD Alarm.

Installation Guide