4010 ATD LT ASSY/OPER/PARTS MANUAL (74303) 12/08

700347-2.WMF 10-28-08

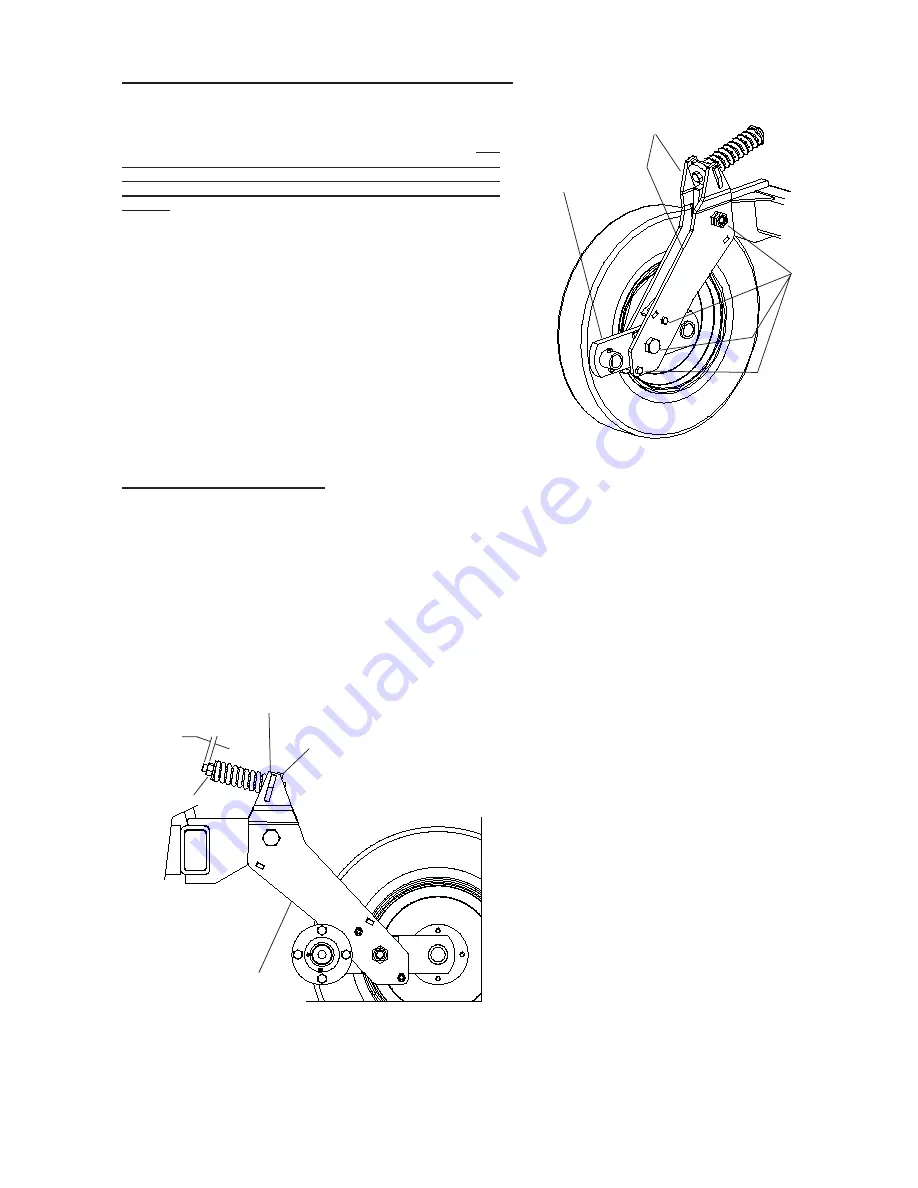

PACKER SPRING SETTINGS

TO MAINTAIN PROPER REAR MACHINE DEPTH THE SPRING ON EACH PACKER ASSEMBLY MUST BE ADJUSTED TO BALANCE THE

WEIGHT OF THE MACHINE AND ALLOW PROPER RELIEF OF THE PACKER WHEELS WHEN ENCOUNTERING UNEVEN TERRAIN.

ONCE THE PACKER PIVOTS HAVE BEEN PROPERLY ADJUSTED AS NOTED ABOVE THE SPRING CAN BE ADDED AND THE SPRING

NUTS ADJUSTED. THIS SHOULD BE DONE WHEN THE UNIT IS COMPLETELY ASSEMBLED AND LEVELLED ON A FLAT SURFACE

PRIOR TO GOING TO THE FIELD. LOWER THE UNIT SO THE SHANKS OR INJECTORS JUST CLEAR THE GROUND.

ALL SPRINGS SHOULD BE SET TO MAINTAIN CONTACT BETWEEN THE SPRING PLATE AND THE FRAME STOP ON EACH PACKER

PIVOT. THIS SETTING IS DEPENDENT ON THE LOAD THAT IS SEEN BE EACH PACKER. SINCE THERE IS MORE WEIGHT ON MOST

OF THE MAIN FRAME PACKERS THE SPRING SETTING (SS) WILL BE GREATER THAN REQUIRED ON THE OUTER WINGS. SET THE

SPRING DISTANCE (SS) ON ALL SPRINGS TO MAINTAIN THE SPRING PLATE TO FRAME STOP CONTACT WITH THE WEIGHT OF

THE UNIT. WHEN PROPERLY SET THE PACKERS SHOULD NOT MOVE EXCESSIVELY UNLESS THE PACKER WHEELS ENCOUNTER

UNEVEN GROUND OR AND OBSTRUCTION.

1) WITH THE MAIN FRAME LEVEL TIGHTEN THE SPRING

BOLT TO A (SS) DISTANCE OF APPROXIMATELY 3/8"-1/2"

ON ALL THE MAIN FRAME PACKERS.

2) TIGHTEN THE PACKER SPRINGS ON THE INNER

PORTION OF THE INNER WINGS TO A (SS) DISTANCE OF

3/8"-1/2" WITH THE REMAINING WING PACKER SPRINGS

TO A LESSER DISTANCE.

3) DEPENDING ON THE WEIGHT AND SIZE OF THE UNIT

TIGHTEN THE REMAINING PACKER SPRINGS ON THE

OUTER WINGS TO A 1/4" TO 3/8" DIMENSION.

4) CHECK TO ENSURE THAT THE SPRING PLATE TO

FRAME STOP CONTACT IS MAINTAINED TO ENSURE THAT

ALL PACKERS ARE SET TO THE SAME DEPTH.

5) PROCEED TO COMPLETING THE FIELD SETTINGS

AND CHECK TO SEE THAT THE STOP CONTACT IS

MAINTAINED AS THE UNIT MOVES THROUGH THE FIELD.

IF THE PACKER PIVOT ARMS ARE MOVING EXCESSIVELY

DUE TO NORMAL LOADING, NOT OBSTRUCTIONS,

TIGHTEN THE SPRING NUTS. TIGHTEN SPRINGS ONLY

TO THE POINT OF MAINTAINING SPRING PLATE TO

FRAME STOP CONTACT WHILE OPERATING. EXCESS

SPRING PRESSURE WILL RESTRICT RELIEF WHEN

PACKER

ADJUST

POINTS

PACKER ASSEMBLY/SETTING INFORMATION

ONCE EACH PACKER ASSEMBLY HAS BEEN COMPLETED WITHOUT

MOUNTING THE SPRING, IT IS CRITICAL TO PROPERLY SET THE

TIGHTNESS OF THE PACKER ADJUST POINTS INDICATED.

THE

SPRING LOADED PACKER ASSEMBLIES WILL NOT FUNCTION

PROPERLY IF THE NOTED POINTS ARE OVER TIGHTENED. BOTH

THE SPRING PIVOT ARMS AND PACKER WALKERS MUST ROTATE

FREELY.

TIGHTEN THE UPPER AND LOWER MAIN PIVOT BOLTS BY

ADJUSTING THE INNER JAM NUT. CHECK TO ENSURE THE ARMS

AND WALKER ARE FREE TO PIVOT. HOLD THE INNER JAM NUT WITH

A WRENCH AND LOCK WITH THE OUTER JAM NUT.

DO NOT USE AN

AIR WRENCH TO TIGHTEN ANY OF THE PACKER ADJUST POINTS.

SPRING PIVOT ARMS

PACKER WALKER

IF THE PACKER ADJUST POINTS ARE TIGHT THE SPRING WILL NOT

RETURN THE SPRING ARMS TO THE CORRECT POINT AND THE

DEPTH CONTROL AND PACKING OF THE REAR OF THE UNIT WILL BE

INCONSISTENT. WITH THE PACKER ARMS AND WALKERS ABLE TO

ROTATE AND THE SPRINGS SET AS NOTED BELOW THE PACKERS

SHOULD CARRY THE REAR OF THE UNIT AT A CONSISTENT

DEPTH AND ALLOW THE SPRING LOADED ARMS TO PIVOT WHEN

OBSTACLES ARE ENCOUNTERED

.

700347-1.WMF 10-28 -08

SS- SEE

2) AND 3)

SPRING PLATE

FRAME STOP

SPRING NUT

PACKER PIVOT ARMS

27