©Copyright Amkus Rescue Systems, Inc. 2018-2020

LAA-002 March 10, 2020 Rev02

8

7.0 ROPE SETUP AND GETTING STARTED

7.1 HOIST WRAPS

The ARRS1 is a force multiplying system. With a small amount of tailing force, force exerted by the user, becomes a much larger

force exerted by the hoist. This multiplication comes from the coe

ffi

cient of friction between the rope and drum as it spins. The amount

of force generated is proportional to the amount of wraps around the drum. As a rule, it is appropriate to keep about 20 lbs.(89N)

tailing force for any load. Pulling force generated by the hoist can be calculated using the formula below.

Pulling Force (lbf or N) = Tailing force*e^(0.175*

μ

* turns) (rad)

Tailing Force (lbf or N)

Data calculated with coe

ffi

cient of friction

μ

= 0.125.

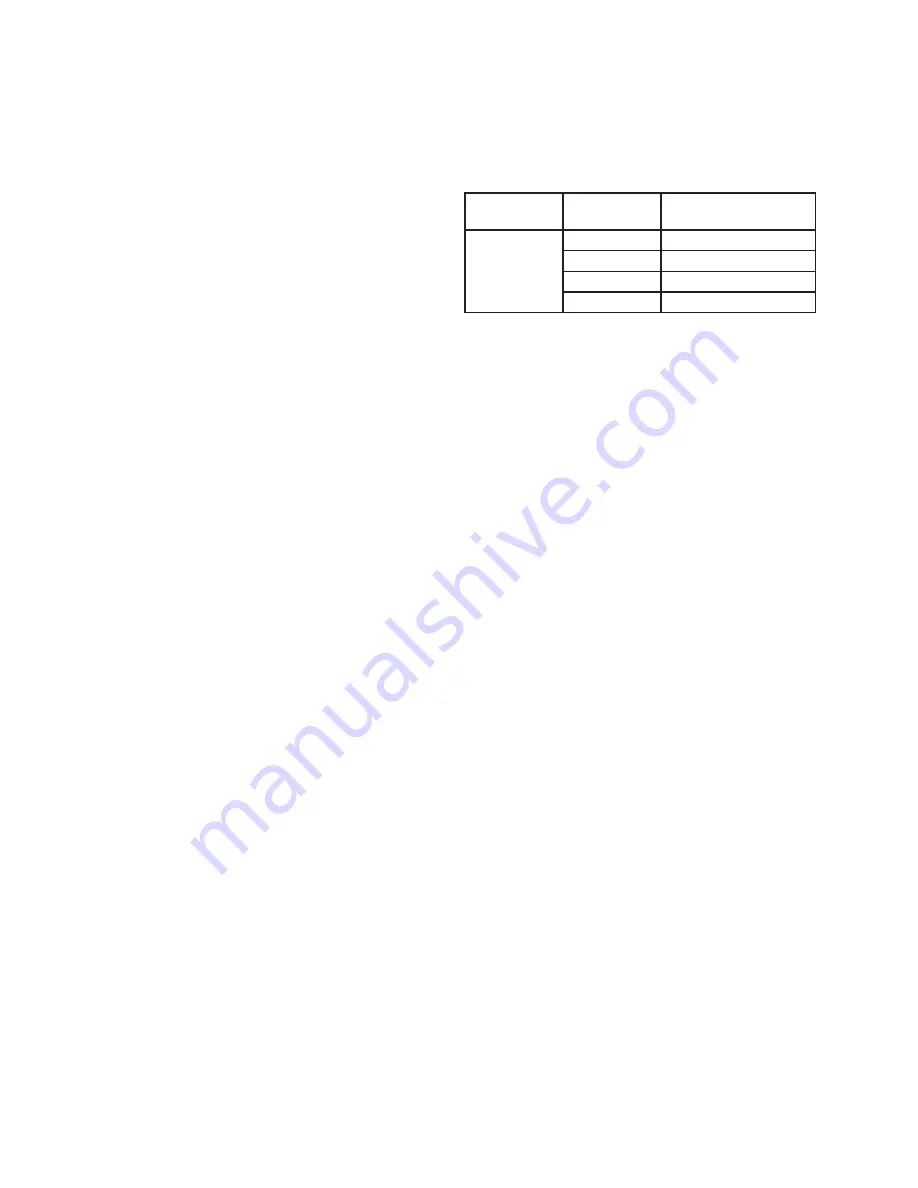

User Tailing

Force

Number of

Rope Wraps

Estimated

Pulling force

20 lbs (89 N)

2

96 lbs (193 N)

3

214 lbs (952 N)

4

469 lbs (2086 N)

5

1031 lbs (4586 N)

7.2 IMPACT FORCES

Tension in the rope is created by the load being lifted. Rope tension can be magni

fi

ed signi

fi

cantly times if the load is allowed to drop

freely before being arrested by the rope. This is referred to as the impact force. The amount of magni

fi

cation depends on the load,

the properties of the rope, the length of rope, and the drop distance. Generally:

The

sti

ff

er the rope, the greater the magni

fi

cation.

The shorter the rope, the greater the magni

fi

cation.

The farther the drop, the greater the magni

fi

cation.

A typical Life Safety rope with a moderate load can experience more than a doubling of tension if the load is allowed to drop even a

few inches.

Always use dual tandem Prusiks to minimize any free fall distance.

7.3 GETTING STARTED

1. Slide the hitch extension into the vehicle mounted hitch receiver. Align the holes in the hitch extension with the holes through the

receiver. Slide one of the hitch pins through the receiver and extension. Install the hitch pin keeper.

2. Slide the ARRS-1 hoist assembly onto the extension to the stop. (Slide the ARRS-1 hoist assembly onto the extension to the stop

with the capstan and motor vertical.) Place the other hitch pin through the hole. Install the hitch pin keeper.

3. Plug the ARRS-1 into the foot switch, then plug the foot switch into the electrical power source.

4. Remove the upper sheave of the lead block assembly. Place the main line through the lead block assembly. Replace the upper

sheave and wrap the main line around the capstan.

5. Attach triple wrapped, appropriately sized, tandem Prusiks to the main line and the swivel plate on the hoist assembly using

carabiners.

6. Test the operation of the hoist prior to connecting the load.

7. Connect the separate belay lines.

8. Connect the main line to the load.

9. You are now ready to raise or lower.

Note* The speed at which the load is raised is directly dependent upon the speed with which the operator tails the rope, and not the

speed of the capstan.