5.7 Main te nance ma chine

5.7.1 Clean ing

•

Clean the ma chine on a daily ba sis.

•

Af ter clean ing all ca bles, hoses, con nec tions and con nec tors

are to be checked for leak age, holed con nec tions, chaf ing

points and other dam age.

•

De tected faults are to be elim i nated im me di ately.

5.7.2 Tight en ing torque

Strength grades for screws with un treated, unlubricated sur faces.

The val ues show 90% use of the yield strength; at a fric tion co ef -

fi cient of µ

tot

= 0.14.

Tight en ing torque is con trolled with torque wrenches.

The val ues given do not ap ply when MoS2 lu bri ca tion is used.

5. Main te nance

61

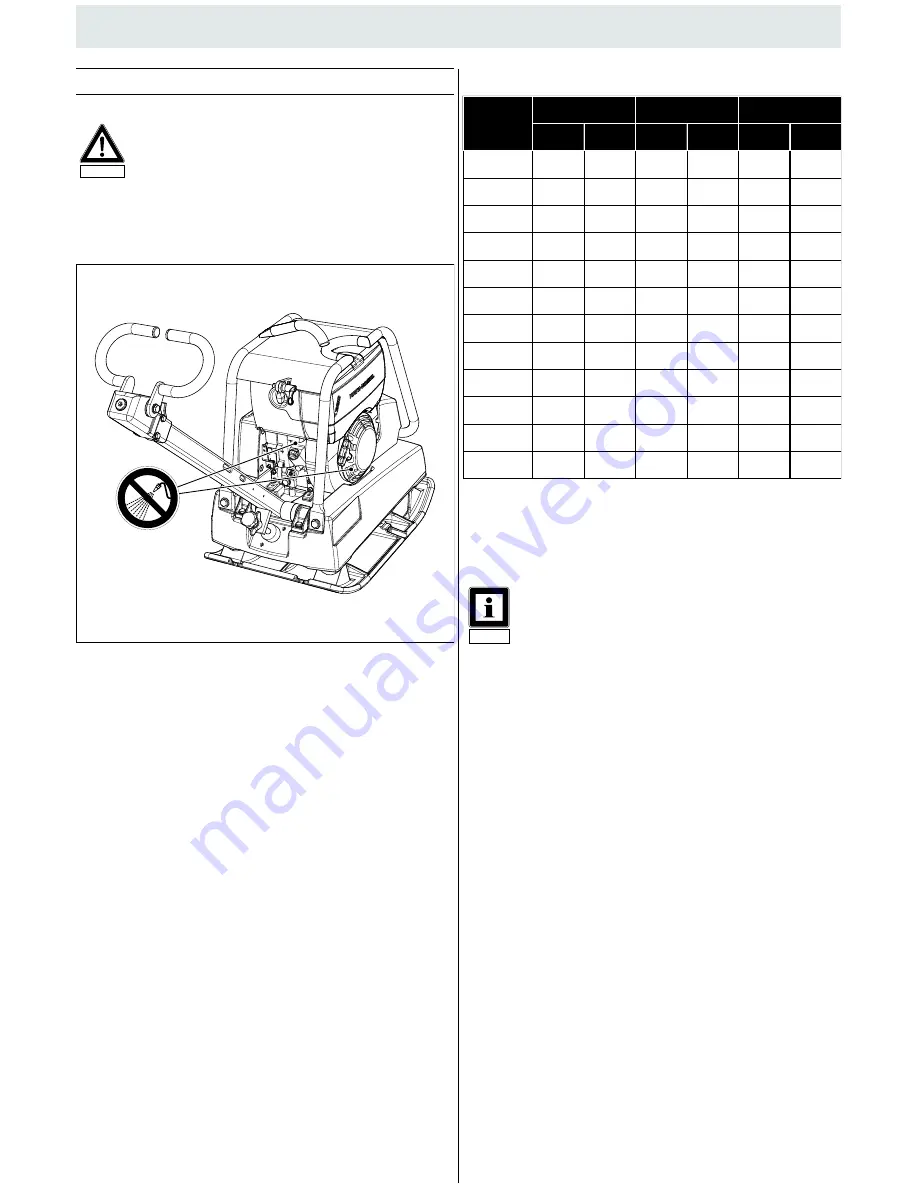

Attention

For clean ing, do not use any flam ma ble or ag gres -

sive ma te ri als.

When clean ing the ma chine with a pres sure

washer, do not spray the elec tri cal com po nents di -

rectly.

When clean ing the ma chine with a pres sure

washer, do not hold it di rectly over the air fil ter.

B3299090

M 4

M 5

M 6

M 8

M 10

M 12

M 14

M 16

M 18

M 20

M 22

M 24

3

2

6

10

25

49

85

135

210

300

425

580

730

4

7

18

36

62

99

154

221

313

427

538

4,4

8,7

15

36

72

125

200

310

430

610

830

1050

3

6

11

26

53

92

147

228

317

449

612

774

5

10

18

43

84

145

235

365

500

710

970

1220

4

7

13

31

61

106

173

269

368

523

715

899

8.8

Nm

ø

Nm

Nm

ft lb

ft lb

ft lb

10.9

12.9

TAB01001.cdr

Important

Re place all self-lock ing nuts af ter each dis as sem bly.