178

ASC110 / ASC130 / ASC150

3.6.

Individual Operations of Maintenance

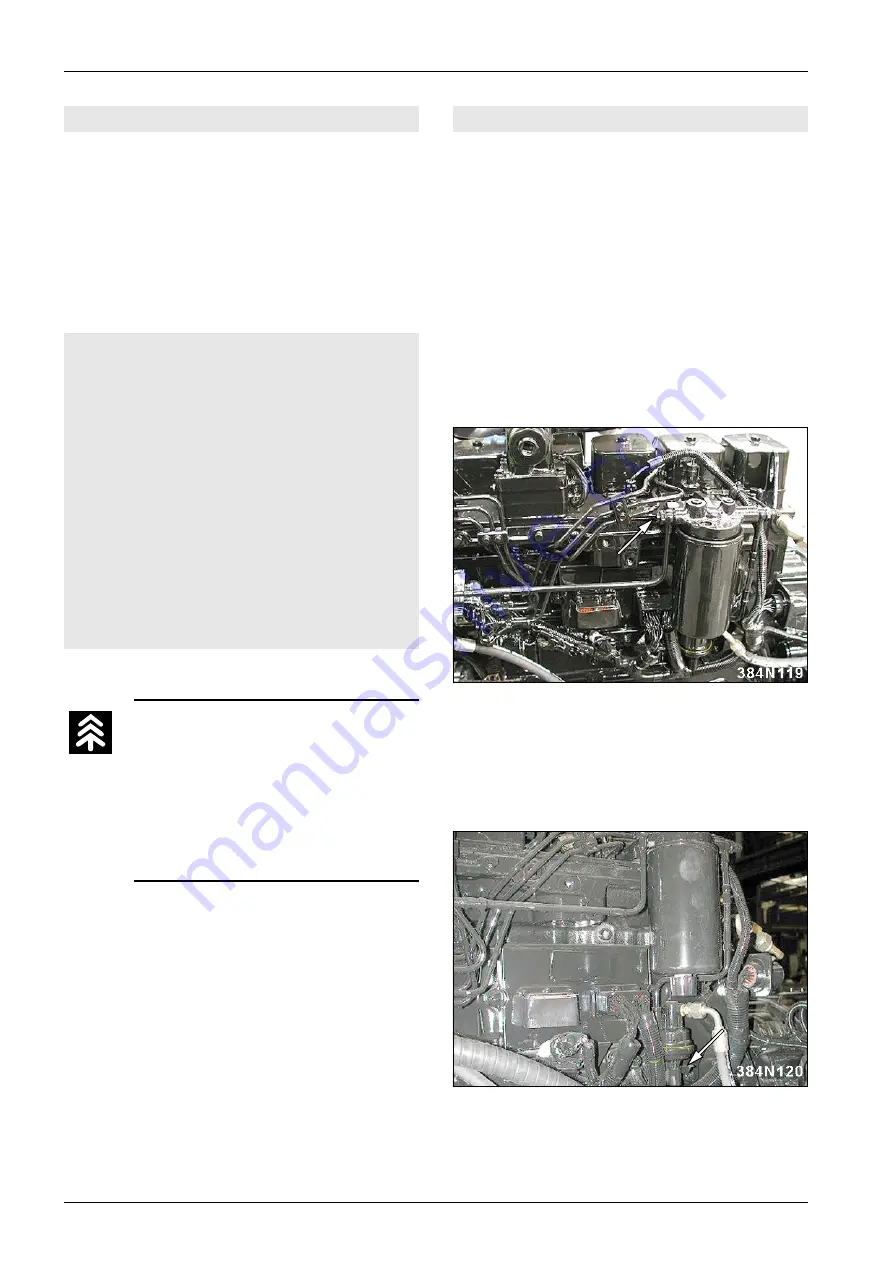

3.6.37. Fuel system venting

NOTE

Check the joints and sealing on the fuel feed piping from

the fuel tank to the feed pump. Check if fuel does not leak

in loose joints and defective sealing on the piping from the

feed pump to the injection pump.

Low-pressure manifold and filters venting:

•

Loosen the vent screw on the fuel filters.

•

Pump fuel with the feed pump until pure and without air

bubbles fuel flows out. Tighten the vent screw applying

the tightening torque of 9 Nm (7 ft lb).

Maintenance - As Needed

Maintenance - As Needed

3.6.36. Cleaning the machine

•

Clean the machine from major impurities after finis-

hing your work.

•

Perform overall cleaning regularly at least once in a

week. When working in cohesive soils, cement and

lime stabilisation’s, the overall cleaning must be per-

formed daily.

! NOTE !

Blind all openings into which the cleaning agent

might penetrate (e.g. engine inlet opening) prior to

pressure water washing. Remove these blinders

after washing the machine.

Do not expose electric parts or insulation material

to direct water or steam flow. Always cover such

materials (inside of the alternator etc.).

Disconnect batteries using the isolating master

switch.

Work with stopped engine.

Do not use aggressive and highly inflammable

cleaning agents (e.g. petrol or highly inflammable

materials).

Follow environmental standards and regulati-

ons when cleaning the machine!

Clean the machine in a site equipped with an

intercepting system for cleaning agents so that

the soil and water sources are not contamina-

ted!

Do not use forbidden cleaning agents!

Summary of Contents for ASC 130

Page 1: ...Operating manual E ASC 130 Cummins Tier II 5 2006...

Page 4: ...4 ASC 130...

Page 6: ...ASC 130...

Page 12: ...10 ASC 130...

Page 13: ...11 ASC 130 1 SPECIFICATION MANUAL ASC 130...

Page 34: ...32 ASC 130...

Page 35: ...33 ASC 130 SPECIFICATION MANUAL...

Page 36: ...34 ASC 130 N s e t o...

Page 37: ...35 ASC 130 SPECIFICATION MANUAL N s e t o...

Page 38: ...36 ASC 130 N s e t o...

Page 39: ...37 ASC 130 SPECIFICATION MANUAL N s e t o...

Page 40: ...38 ASC 130...

Page 42: ...40 ASC110 ASC130 ASC150 ASC200 ASC250...

Page 56: ...54 ASC110 ASC130 ASC150 ASC200 ASC250...

Page 64: ...62 ASC110 ASC130 ASC150 ASC200 ASC250 2 6 Controls and control devices...

Page 66: ...64 ASC110 ASC130 ASC150 ASC200 ASC250 2 6 Controls and control devices...

Page 68: ...66 ASC110 ASC130 ASC150 ASC200 ASC250 2 6 Controls and control devices...

Page 70: ...68 ASC110 ASC130 ASC150 ASC200 ASC250 2 6 Controls and control devices...

Page 72: ...70 ASC110 ASC130 ASC150 ASC200 ASC250 2 6 Controls and control devices...

Page 87: ...85 ASC110 ASC130 ASC150 ASC200 ASC250 OPERATING INSTRUCTIONS...

Page 122: ...120 ASC110 ASC130 ASC150 ASC200 ASC250 N s e t o...

Page 123: ...121 ASC110 ASC130 ASC150 ASC200 ASC250 OPERATING INSTRUCTIONS N s e t o...

Page 124: ...122 ASC110 ASC130 ASC150 ASC200 ASC250...

Page 125: ...123 ASC110 ASC130 ASC150 3 MAINTENANCE MANUAL ASC 110 ASC 130 and ASC 150 Cummins tier 2...

Page 126: ...124 ASC110 ASC130 ASC150...

Page 134: ...132 ASC110 ASC130 ASC150 3 4 Lubrication and Maintenance Chart...

Page 135: ...133 ASC110 ASC130 ASC150 MAINTENANCE MANUAL...

Page 136: ...134 ASC110 ASC130 ASC150 3 5 Lubrication Chart...

Page 186: ...184 ASC110 ASC130 ASC150 3 6 Individual Operations of Maintenance...

Page 189: ...187 ASC110 ASC130 ASC150 MAINTENANCE MANUAL...

Page 190: ...188 ASC110 ASC130 ASC150 3 8 Appendixes...

Page 191: ...189 ASC110 ASC130 ASC150 MAINTENANCE MANUAL...

Page 193: ...191 ASC110 ASC130 ASC150 MAINTENANCE MANUAL...

Page 195: ...193 ASC110 ASC130 ASC150 MAINTENANCE MANUAL...

Page 196: ...194 ASC110 ASC130 ASC150 3 8 Appendixes N s e t o...

Page 197: ...195 ASC110 ASC130 ASC150 MAINTENANCE MANUAL N s e t o...

Page 198: ...N s e t o...