7.1

Main tain ing the ma chine

7.1.1

Clean ing

•

Clean the ma chine daily.

•

Af ter clean ing, check the ca bles, hoses, wires and screw con -

nec tions for leaks, loose con nec tions, chaf ing and other dam -

age.

•

Re pair any de fects you see.

7.1.2

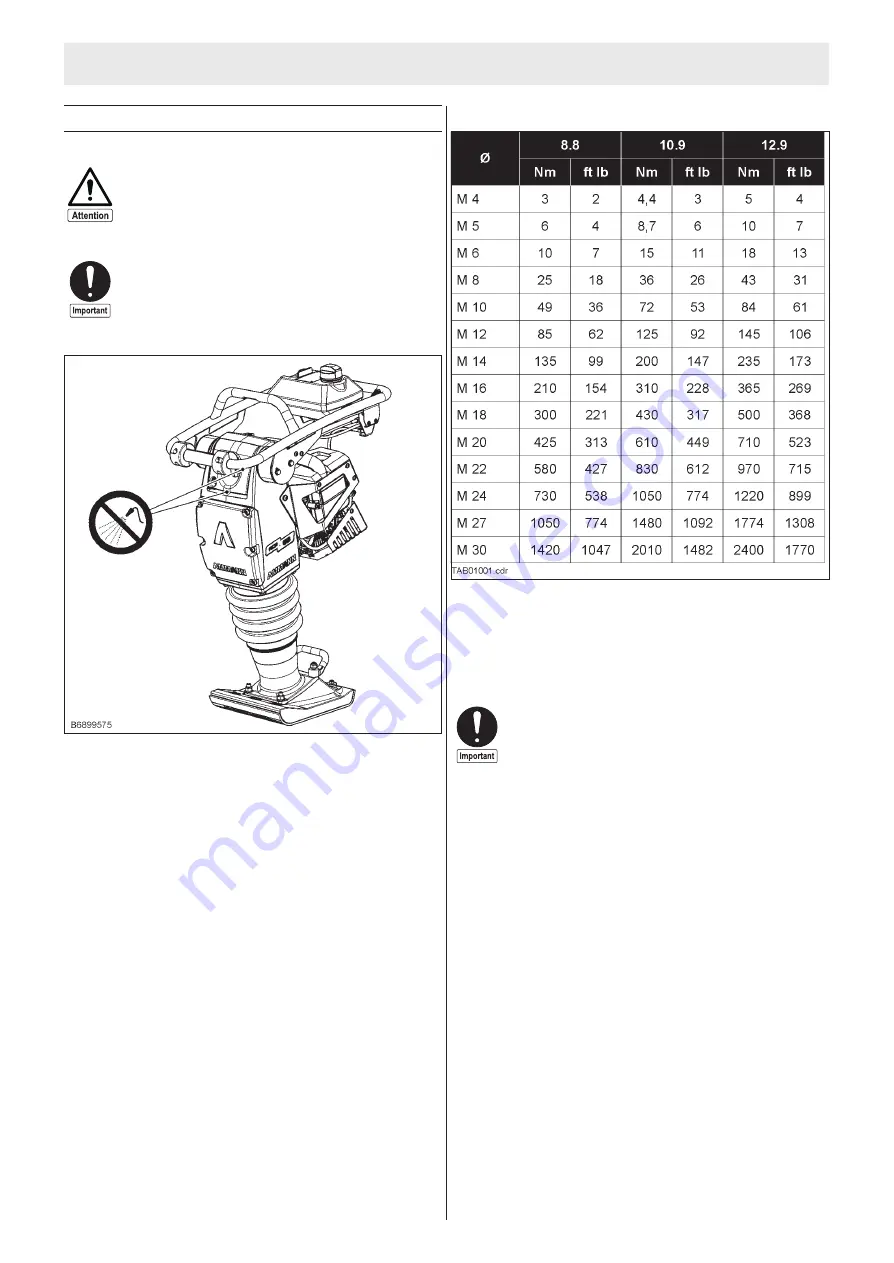

Tight en ing torque

Strength grades for screws with un treated, unlubricated sur -

faces.

The val ues show 90% use of the yield strength; at a fric tion co ef -

fi cient of µ

tot

= 0.14.

Tight en ing torque is con trolled with torque wrenches.

The val ues given do not ap ply when MoS2 lu bri ca tion is used.

02

03

10

00-

2

Hb

m

G

gn

u t

hci

dr

eV

nn

a

m

mA

71

02/

70

7. Main te nance Machine

61

Risk of fire and ex plo sion caused by in flam ma ble

sub stances.

•

For clea ning, do not use any flam ma ble or ag -

gres si ve ma ter ials.

Re place all self-lock ing nuts af ter each dis as sem bly.

When clea ning the ma chi ne with a pres su re was her,

do not spray the elec tri cal com po nents di rect ly.

When clean ing the ma chine with a pres sure washer,

do not hold it di rectly over the air fil ter.

Summary of Contents for ATR 60 C

Page 2: ......

Page 40: ......

Page 74: ......

Page 108: ......

Page 141: ......

Page 142: ...1 2 0 3 1 0 0 0 2 H b m G g n u t h c i d r e V n n a m m A 7 1 0 2 7 0...

Page 143: ......

Page 144: ...1 2 0 3 1 0 0 0 2 H b m G g n u t h c i d r e V n n a m m A 7 1 0 2 7 0...

Page 145: ......

Page 146: ...1 2 0 3 1 0 0 0 2 H b m G g n u t h c i d r e V n n a m m A 7 1 0 2 7 0...

Page 147: ......

Page 148: ...1 2 0 3 1 0 0 0 2 H b m G g n u t h c i d r e V n n a m m A 7 1 0 2 7 0...

Page 149: ......

Page 150: ...1 2 0 3 1 0 0 0 2 H b m G g n u t h c i d r e V n n a m m A 7 1 0 2 7 0...

Page 151: ......

Page 152: ...1 2 0 3 1 0 0 0 2 H b m G g n u t h c i d r e V n n a m m A 7 1 0 2 7 0...

Page 153: ......