Exploded View

Ampco Pumps Company

Page 15

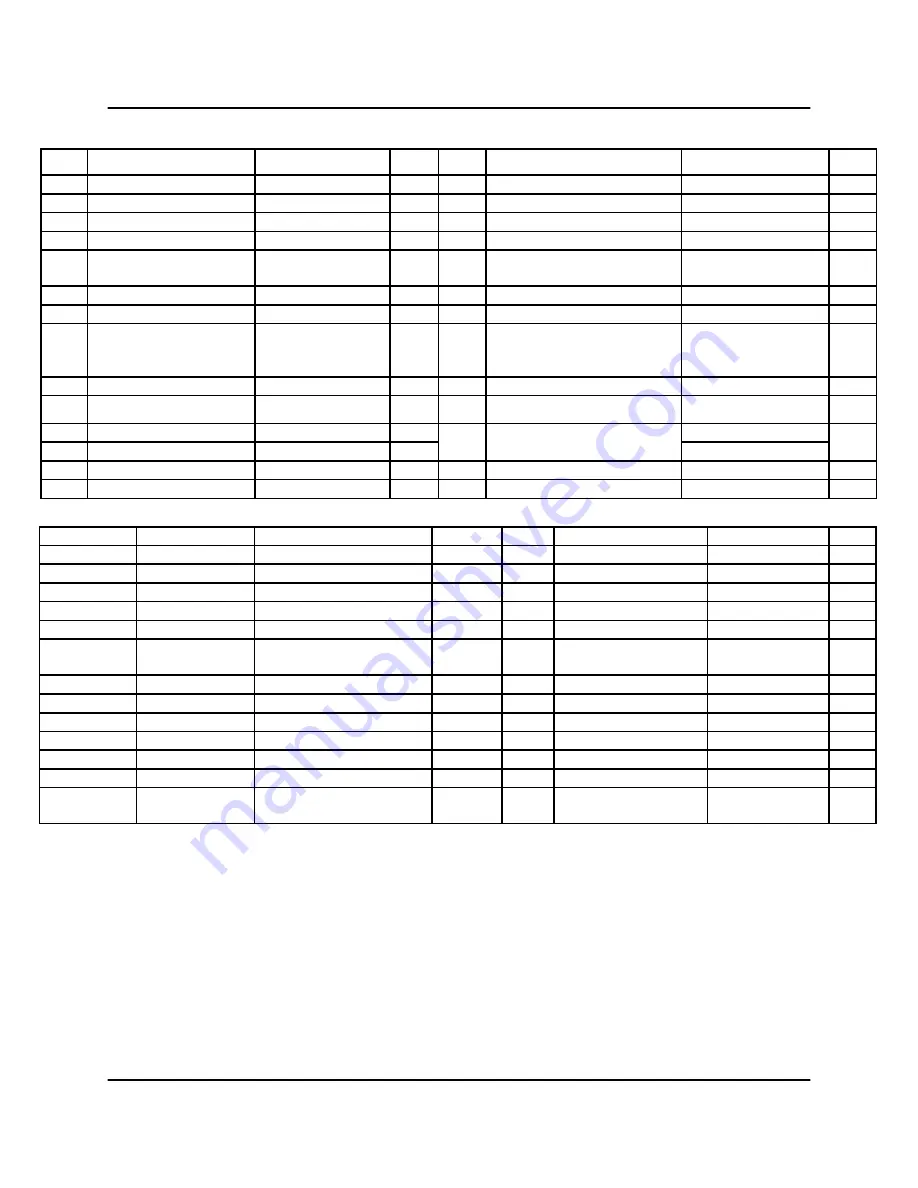

Parts List:

AC+2116

Key

Description

Part Number

Qty

Key

Description

Part Number

Qty

1

Hopper

DBH2116-2-TC

1

15

Casing Gasket

S216-90A-U

1

2

(2”) Clamp

13MHHM200

2

18

Casing Clamp

S216-75AR-S

1

3

(2”) Gasket

40MP-U200

2

19

Deflector/Slinger

DBX8207351

1

4

(2”) Butterfly Valve

B5101E200CC-C

1

20

Impeller Key

S216-95C-316L

1

5

Diffuser/Dry Feed

Tube

DBX2116-200D

1

21

Stub shaft

C216E-18TP-06

1

6

(2.5”) Clamp

13MHHM250

2

22

Shaft Collar Screw

GX5494026SS

1

7

(2.5”) Gasket

40MP-U250

2

23

Shaft Collar

SX18000014

1

8

Inlet Adapter

DBX2116-250W

1

24

Adapter Cap Screw

(D) GX5079700

(DG) SC1710H-SS

(E) SC1106E-SS

4

9

Pump Casing

S316DB-01C-E

1

25

Seal Guard

C216-18T-131-S

1

10

Casing Screen

DBX8307982

1

27

Adapter

216D18T-71DB-SS

1

11

Impeller Nut

S216-91C-316L

1

28

Platform/Base

DBB2116-180

12

Impeller Nut Gasket

S216-25A-U

1

DBB2116-210

13

Impeller

S216-02DB-316L

1

29

Motor

Optional

1

14

Impeller Back Gasket

S216-25B-U

1

30

O-Ring, Rotor Hub

N70224

1

1

D1

Carbon Seal

216E-80-1A

1 (D)

E1

Carbon Seal

216E-80-1A

2

D2

Seal O-Ring

01-1165-19-U

1

E2

Seal O-Ring

01-1165-19-E

2

D3

Cup D

216D-80-3P

1

E3

Cup E

216E-80-3P

2

D4

Spring D

216D-80-4

1

E4

Drive Collar E

216E-23-316L

1

D5

Drive Collar D

SP216D-23P-S

1

E5

Spring E

216E-80-4A

1

D6

Set Screws

SC1105A-SS

3

E6

Set Screws

SC1103A-SS

3

D7

Back plate D

(D) 216D-11-316

(DG) SP216G-11-316L

1

E7

Stuffing Box

216E-83B-316

D8

Gasket -Thick

SP216G-80-12AG

1

E8

Back plate E

216E-11B-316

1

D9

Seal Seat

SP216G-80-11SC

1

E9

Follower

216E-17-316

1

D10

Gasket -Thin

SP216G-80-12G

1

E10

Lock washer

LWA-1300-SS

4

D11

Gland Ring

SP216G-17-316L

1

E11

Machine Screw

SC1308H-SS

4

D12

Mounting Bolt

GX5076004

4

E12

O-RING

17-122-U

1

D13

Lock Washer

LWA-1300-SS

4

E13

O-Ring

17-275-U

1

D14

Set screw cup

point

GX5494026SS

3

Ampco Pumps Company AC+ Dry Blender Manual M-028 Rev C 12.20