INTRODUCTION

The ILD15 has been designed as a high quality stand-alone induction loop driver

for use in small to medium size lifts, although the rugged construction may be

suited to other industrial applications.

The unit is designed to drive a loop constructed out of custom built metal bars,

which is a very low impedance. Ordinary wire can sometimes be used if it can be

installed inside the lift car, but care must be taken to ensure the loop satisfies the

unit’s load requirements.

The ILD15 comes in a number of different versions

All versions have:

#

two separate audio inputs,

#

230V or 115V AC power supply (factory set option)

#

transformer coupled loop output.

The standard unit has one low-Z speaker line level input and one 100V PA line

input.

Unit versions are indicated by the suffix:

#

BB - Battery back-up (If AC power fails, battery powers unit).

#

NB - No battery back-up.

#

BBL / NBL - As above, but two line level / low Z speaker inputs (and no 100V

PA line input).

All connections (except the ‘Protective Earth Terminal’) are via vibration-resistant

cage clamp terminals which are quick and easy to connect.

QUICK START

1. Fit ILD15 on top of lift where it will not be vulnerable to damage and where

the cables will be protected.

2. Fit loop cable / bars (refer to fitting section)

Ensure loop is insulated from lift body.

3. Connect loop to amplifier using feed cables. Ensure feed pair is twisted

together.

4. Connect Signal Inputs

(see input connection drawings)

using twisted pair

cable.

5. Connect AC power

(see points 5 and 8 in Safety section)

6. Turn ‘Gain 1’, ‘Gain 2’, and ‘Drive’ controls fully anticlockwise (minimum), and

the ‘loss’ control to centre setting.

7. Switch on external power:-

!

(Not ‘NB’ or ‘NBL’ version)

8. Operate internal switch SW2

( not fitted on ‘NB’ or ‘NBL’ version)

!

Check Green ‘Power’ LED illuminates.

10. Apply input signal (eg intercom). Increase the input control until the Green

‘Compression’ LED begins to light.

11. Repeat item10 for the second input (if used).

Only apply one audio signal at

a time when setting up the system.

12. Adjust the DRIVE control until the Yellow ‘Loop Current’ LED lights at peaks

in the input signal.

NOTE: Once the DRIVE control is set, do not adjust it

again.

Check Yellow ‘Battery Charge’ or Green ‘Battery Float’ LED illuminates.

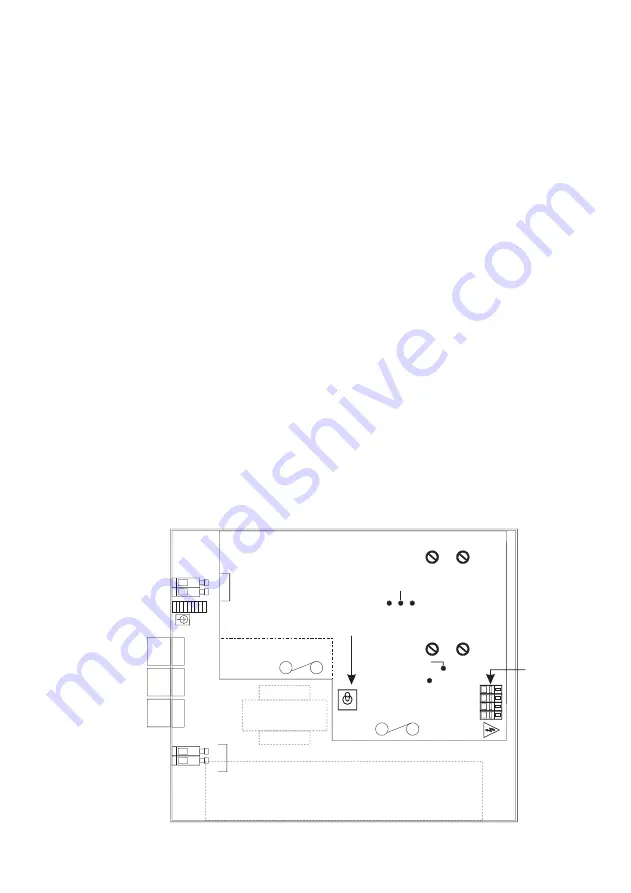

LOOP

AC

POWER

SW2

INPUT 1

INPUT 2

DRIVE

LOSS

COMPRESSION

LOOP CURRENT

POWER

INPUT 2

INPUT 1

In

s

e

rt

s

c

re

w

d

ri

v

e

r

to

o

p

e

n

c

o

n

ta

c

t

BATTERY CHARGE

BATTERY FLOAT

Push plunger

to open contact

before inserting wire.

Push plunger

to open contact

before inserting wire.

AC

POWER

CABLE

AUDIO

INPUT

LOOP

CABLE

C

a

b

le

s

m

u

s

t

b

e

k

e

p

t

in

s

e

p

a

ra

te

b

u

s

h

in

g

s

—

D

o

n

o

t

m

ix

c

a

b

le

s

—

AC POWER FUSE

Under insulating barrier

OFF

NORMAL

BATTERY FUSE

N

L

E

Layout

Basic Wiring

Audio Input signal

Switched

& fused

power

source

Loop

Twisted Pair

Cable to Loop

ILD15