INSTALLATION

Tools

You will require the following:

!

Phillips screwdriver

!

Small flat blade screwdriver

!

Ratchet crimp tool

Location

The amplifier should be mounted where :

!

it is protected from drips or sprays of water

!

it is not vulnerable to mechanical damage

!

the controls can be accessed through the open cover.

The unit must be close to the loop; when used on a lift, it is typically mounted on

top of the lift car.

Cable glands

The ILD15 is supplied with three cable glands to firmly clamp the cables entering

the unit. The AC power, audio inputs & loop output cables should be fed through

the case separately as shown in ‘

Basic Wiring

’. The unit is designed to provide

protection to IP43. This is subject to round wires between 5 and 10mm diameter

being used. Suitable sleeving should be fitted to twisted pair or smaller cables to

enlarge them to within this range.

To further prevent ingress run cables along the mounting surface then up into the

cable glands

Connections

GENERAL: Open the cage clamp terminals using a flat bladed screwdriver. See

‘

Layout

’

drawing for location of each terminal and details of its operation.

LOOP: Connect the loop cable ends to the loop output connector. make sure that

the feed cable (the 2-wire section between the amplifier and loop) is tightly

twisted together and less than 3m in length. In lifts, the loop connecting wires

2

should not be less than 2.5mm (AWG 12) area. See below for loop design

INPUTS: Connect inputs as shown in the diagram. Note that input 2 is different on

the ILD15BB and BBL. Use Low-Z connection for Intercom Speakers, Voice

Announcers, etc, and 100V line for building PA.

For all inputs, use twisted pair cables, preferably with screen.

AC POWER:

The ILD15 can be supplied in 115VAC or 230VAC versions.

Check that the version you have is compatible with your power supply.

Isolate external AC power source before working on power connections

Use the crimp terminal, washer & nut provided to connect incoming AC Earth

OPERATION (

see ‘Layout’ drawing for control names & positions)

1. Turn ‘Gain 1’, ‘Gain 2’ and ‘Drive’ controls fully anti-clockwise.

Set ‘MLC’ control to mid-position.

2. Switch on external AC power

!

Check ‘Battery Charge’ or ‘Battery Float’ LED illuminates.

(Not ‘NB’ version)

3. Set internal switch SW2 to ‘Normal’

(Not fitted on ‘NB’ version)

!

Check Green ‘Power’ LED illuminates.

4. Apply an audio signal to one input

(e.g. speech through an intercom).

Turn the

associated Gain control clockwise until Green ‘Compression’ LED illuminates.

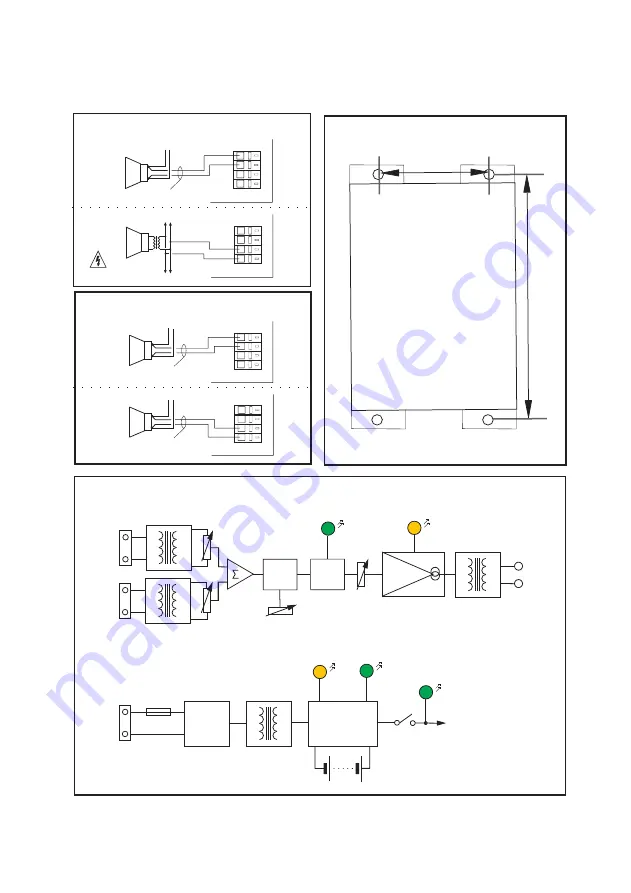

Mo n ing De ai s

u t

t l

160mm

4

0

m

m

2

Top

View

Block Diagram

Compression LED

Output Current LED

Output

MLC Adjust

Drive

Loop

output

115V

230V

Select

Fuse

Power LED

Power

input

Input 1

Input 2

AC Input Version

MLC

AGC

Battery

charger

DC power to

system

Charge

Float

Twist together

Low Z Speaker feed

Inputs

BB & NB Versions

100V speaker line

Input 2

Input 1

ILD15

I/P

1

ILD15

I/P

2

Twist together

Twist together

Low Z Speaker feed

Low Z Speaker feed

Input 1

Input 2

Inputs

BBL & NBL Versions

ILD15

I/P

1

ILD15

I/P

2