L0086, Rev. D

AMS SENSIT II GLASS FRONT VRM VENDOR

7-2

7.2.3 Error Code Causes and Solutions

- Continued

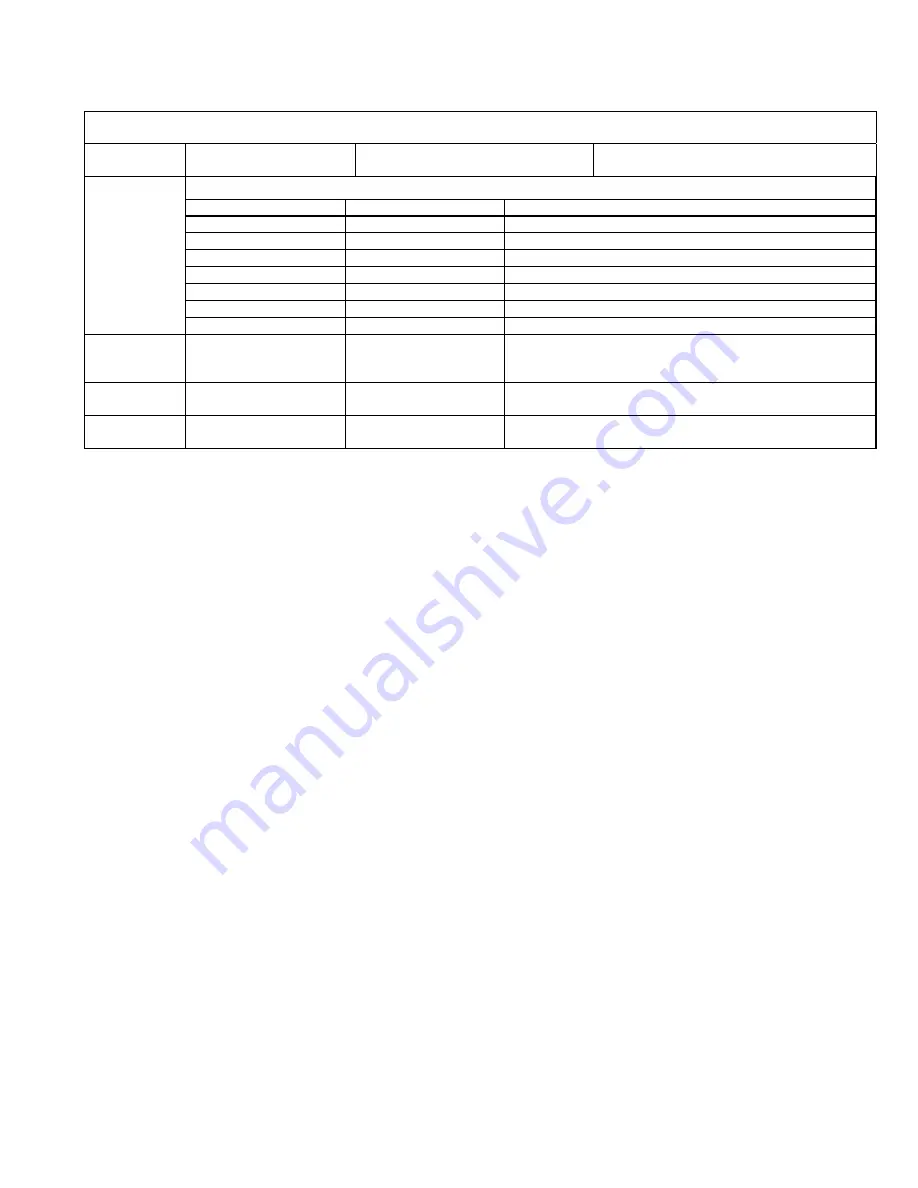

ERROR CODES – CAUSES AND SOLUTIONS

Top Level

Error Code

Sub Level

Code

Causes Solutions

A message has been generated by the card reader.Press

1

to see sub-level error codes.

CARD ERROR –.

Card error

Use a different card.

INVALID CARD –

Invalid card

Use a different card

TAMPER

Tamper error.

Consult card reader manual or manufacture

COMMUNICATIONS 4 Communications error.

Check MDB harness connections

SERVICE

Unit needs service.

Consult card reader manual or manufacturer.

READ ERROR

Reader failure.

Consult card reader manual or manufacturer.

COMMUNICATIONS 9 Communications error

Check MDB harness connections.

CARD

READER

JAMMED CARD

Card is jammed.

Clear the jammed card from the card reader.

PROD.

SENSOR

NONE

The product sensor is

blocked or disconnected.

Remove any products or other objects in the bottom, or in

sensor openings in ends, of the delivery bin. Check sensor

harness connections.

SENSIT

BLOCKED

NONE

The vend sensor is

blocked or lens is fogged.

Remove any obstructions from the path of the sensor.

SENSIT

DISCONN’D

NONE

The vend sensor is

disconnected.

Check sensor harness connections.

7.3 CLEARING JAMMED MOTOR

If one or more motors and helixes become jammed,

the motor(s) will be displayed as a sublevel error under

“Motor Jammed”.

Energized vend motors can turn a helix with

considerable torque, creating a possible entrapment

hazard. Disconnect power to the vendor or control board

before freeing a jammed helix or motor. Always restrain or

block the helix before freeing a jammed or caught product.

CAUTION

:

Use caution when freeing jammed product!

Refer to

2.2.4 Helix Motion and Jamming!

Clear any jammed products from the indicated vend

columns.

To reset the error, first enter service mode (refer to

Section 6.0), then select Tray Setup (refer to Section 6.7.1).

Press “1”, then “ * “, then “3”. The control will attempt to run

the jammed motors. If the motor had been taken out of the

motor matrix, it will be re-established in the matrix.

7.4 WATER ACCUMULATION IN THE CABINET

Water accumulating in the cabinet is usually caused by

one of two things: condensation of moist air or rain water

leaking into the cabinet. Excessive condensation indicates

an air leak which allows moist outside air to continually

enter the cabinet and condense on the evaporator.

To minimize condensation on the evaporator:

1.

Make sure the refrigeration unit cover gasket is sealing

properly all the way around. In particular, check the

openings where the refrigeration lines and drain tube

pass through the cover. These openings should be

sealed completely around the lines and tube with duct

putty.

2.

Make sure the cabinet door is properly tightened when

it is closed so that it makes contact with the gasket on

all sides.

3.

Make sure there are no objects preventing the vend

door from closing. The vend door must open and close

freely and close completely.

Rain water can enter the cabinet through the rear

ventilation opening. Rain entering through this opening is

not considered hazardous since all components of the

refrigeration unit are sealed. Water will drain out through

the ventilation opening in the bottom of the cabinet. Check

to make sure the refrigeration unit cover gasket is seating

properly if excess water is noticed in the front of the

cabinet.

Some water accumulation on the inside bottom area of

the cabinet door is expected and should drain out on its

own. Check to make sure the rain guards on the top of the

door and cabinet are present and functioning properly to

minimize water coming in around the door gasket

Summary of Contents for 39-VRM

Page 2: ......

Page 6: ...L0086 Rev D AMS SENSIT II GLASS FRONT VRM VENDOR iv ...

Page 16: ...L0086 Rev D AMS SENSIT II GLASS FRONT VRM VENDOR 3 4 ...

Page 24: ...L0086 Rev D AMS SENSIT II GLASS FRONT VRM VENDOR 5 4 ...

Page 30: ...L0086 Rev D AMS SENSIT II GLASS FRONT VRM VENDOR 6 6 ...

Page 40: ...L0086 Rev D AMS SENSIT II GLASS FRONT VRM VENDOR 8 6 ...

Page 48: ...L0086 Rev D AMS SENSIT II GLASS FRONT VRM VENDOR 11 2 ...

Page 50: ...L0086 Rev D AMS SENSIT II GLASS FRONT VRM VENDOR 12 2 ...