30

AM-TC10626LA

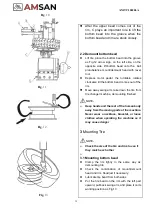

Fig

.6

Fig

.7

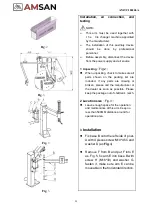

⚫

Fix arm I into arm E as Fig.6 fasten

it with screw K and washer J.

⚫

As Fig.6, loose switch rod M at

clockwise, insert rod N into the

hole on the arm, lock N with switch

M at anti-clockwise, install L into

N, install centering cone P into O,

arm installation finished.

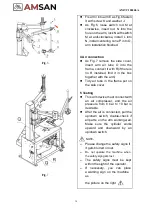

4 Air connection

⚫

As Fig.7 remove the side cover,

insert arm air tube O into the

frame, connect it with R(if there is

no R installed, find it in the box

together with the arm)

⚫

Tidy air tube in the frame put on

the side cover.

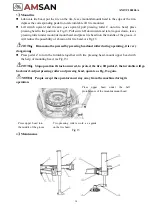

5 Testing

⚫

This arm device must connect with

an air compressor, and the air

pressure from 8 bar to 10 bar is

desirable.

⚫

After the air is connected, pull the

up/down switch, double-check if

all parts on the arm working well.

Make sure the cylinder works

upward and downward by an

up/down switch.

NOTE

:

➢

Please change the safety signs if

it gets blurred or lost

.

➢

Do not operate the machine when

the safety sign gets lost

.

➢

The safety signs must be kept

within the sight of the operator

.

➢

If necessary, you can place

a warning sign on the machine

as

the picture on the right

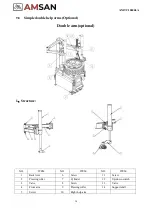

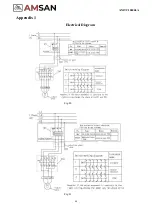

Summary of Contents for AM-TC10626LA

Page 1: ...PLEASE READ THE PRODUCT MANUAL ENTIRELY BEFORE INSTALLING OR OPERATING THE LIFT ...

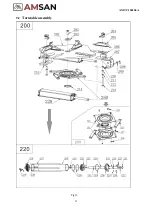

Page 22: ...Fig 34 21 AM TC10626LA 9 1 Column assembly 9 Exploded drawings ...

Page 23: ...Fig 35 22 AM TC10626LA 9 2 Turntable assembly ...

Page 24: ...Fig 36 22 AM TC10626LA 9 3 Gearbox motor assembly ...

Page 25: ...24 AM TC10626LA 9 4 Body assembly Fig 37 ...

Page 26: ...25 AM TC10626LA 9 5 Bead Breaker Cylinder Breaker Arm Assembly Fig 38 ...

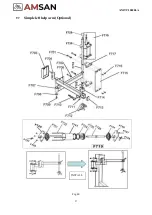

Page 27: ...26 AM TC10626LA 9 6 Quick inflating system Optional Fig 39 ...

Page 28: ...27 AM TC10626LA 9 7 Simple left help arm Optional Fig 40 INSTALL ...

Page 41: ...40 AM TC10626LA Appendix 1 Electrical Diagram Fig 40 Fig 41 ...