AM-TC10626LA

31

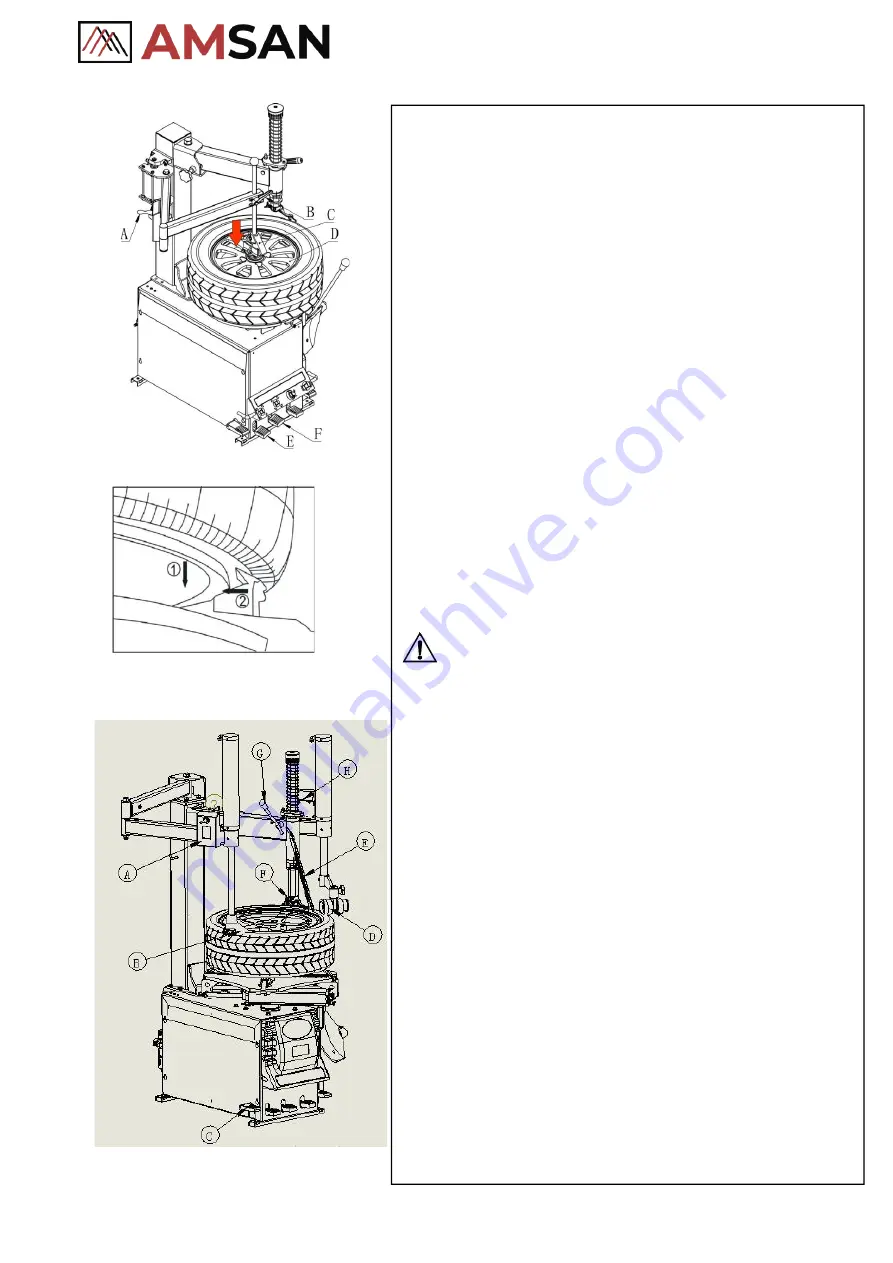

Fig

.8

Fig

.9

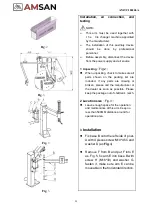

Operation

⚫

This help arm has been designed to facilitate the

operations of tire mounting/demounting. In any case,

this device would make these jobs easier on any type

of wheel.

⚫

All work on the electrical system, including minor operations,

must be carried out by professionally qualified personnel

!

Check that the electrical supply voltage and air supply is the

same as that indicated on the plate of the machine

1 Rim clamping

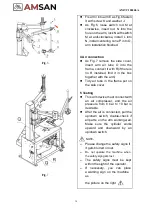

⚫

As per the instruction on the manual, lose the tire from

its two sides with a shovel and lubricate the tire bead

⚫

Press pedal E, four jaws start to open and make the

jaws open till big enough to clamp the rim, put the tire

on the turntable. As Fig 8

⚫

Lift switch A and cylinder reach its highest position,

pull switch B down to loose rod and let centering cone

going to the middle of the rim, pull up switch B to lock

rod.

⚫

Pull down switch A and let rim down as Fig,9, again

press pedal F to make rim clamped by the four jaws.

NOTE

:

➢

We Suggest clamping rim from outside, not clamping

rim from inside (if locking rim inside, damage or

danger may occur, such as tire falling, rim damaged.)

。

2

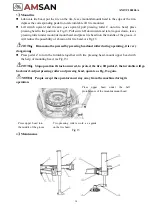

Demounting the tire

2.1

Demounting the upper bead

⚫

Refer to tire changer machine manual, pull swing arm

to its working area, release handle G, move pressing

roller D onto the tire bead as Fig.10, lock hand G, pull-

down switch H, loose tire bead ahead of

mount/demount head.

⚫

Insert lever E from top of mount/demount head,

release pressing roller D and move away from its arm,

pull down switch A, let B press down tire bead

reasonably, press lever E and let upper bead goes

onto mount/demount head, depress pedal C to rotate

turntable till upper bead comes out of the rim.

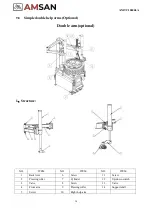

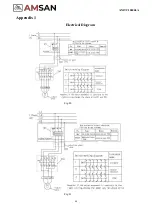

Summary of Contents for AM-TC10626LA

Page 1: ...PLEASE READ THE PRODUCT MANUAL ENTIRELY BEFORE INSTALLING OR OPERATING THE LIFT ...

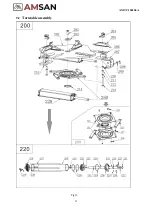

Page 22: ...Fig 34 21 AM TC10626LA 9 1 Column assembly 9 Exploded drawings ...

Page 23: ...Fig 35 22 AM TC10626LA 9 2 Turntable assembly ...

Page 24: ...Fig 36 22 AM TC10626LA 9 3 Gearbox motor assembly ...

Page 25: ...24 AM TC10626LA 9 4 Body assembly Fig 37 ...

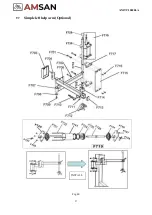

Page 26: ...25 AM TC10626LA 9 5 Bead Breaker Cylinder Breaker Arm Assembly Fig 38 ...

Page 27: ...26 AM TC10626LA 9 6 Quick inflating system Optional Fig 39 ...

Page 28: ...27 AM TC10626LA 9 7 Simple left help arm Optional Fig 40 INSTALL ...

Page 41: ...40 AM TC10626LA Appendix 1 Electrical Diagram Fig 40 Fig 41 ...