33

AM-TC10626LA

图

16

图

16

Fig

.14

Fig

.15

Fig

.16

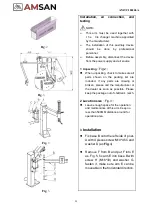

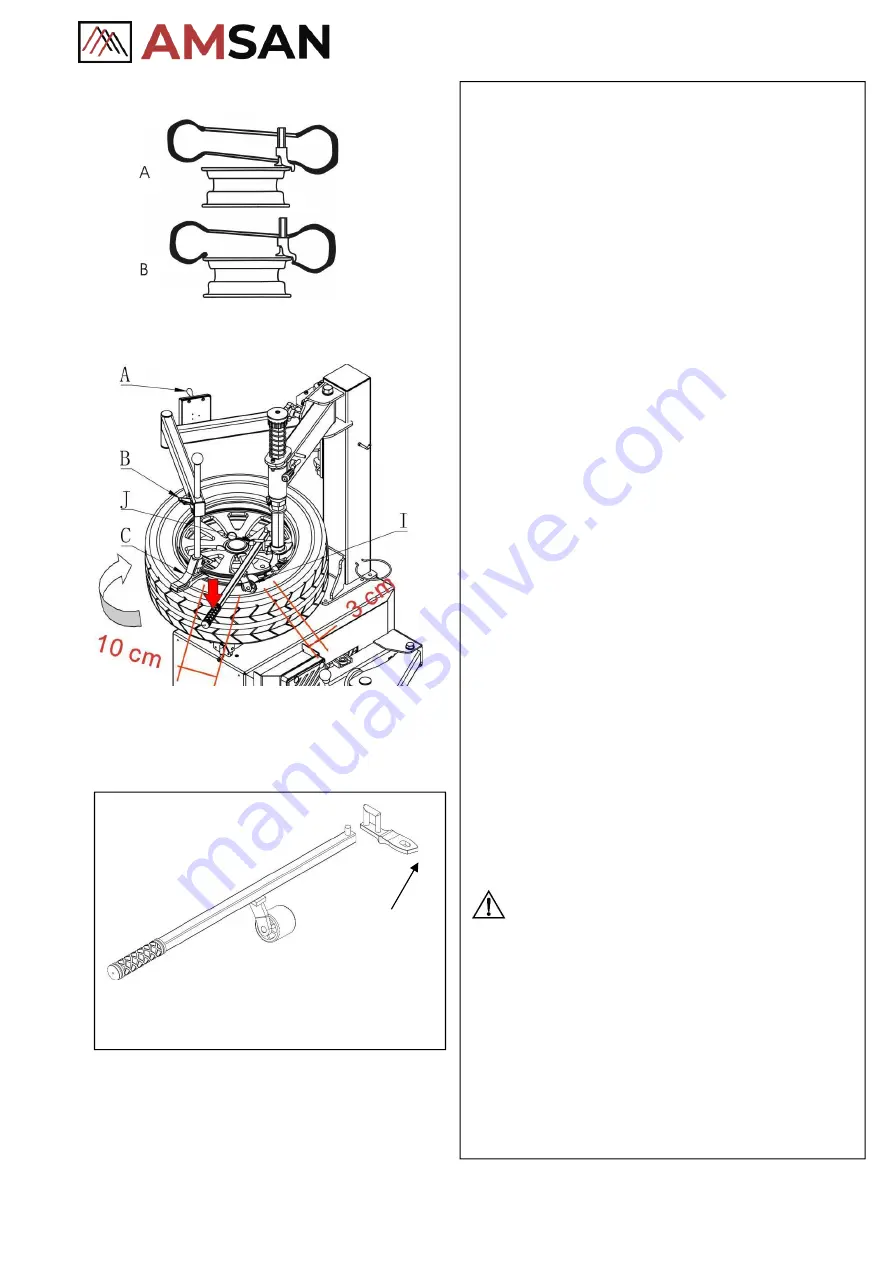

⚫

Adjust relative position between the tire bead and

mount/demount head, let the tire bead cross the

mount/demount head. At the end of the

mount/demount head, the tire bead should be

placed on the mount/demount head as fig. 14-A

;

At the beginning of the mount/demount head, the

tire bead should be placed under the ball

protuberance of the mount/demount head

(

as

fig.14-B

)

⚫

Press down the central part of the tire. Depress the

corresponding pedal to rotate the turntable

clockwise, making the lower tire bead fall into the

rim groove completely

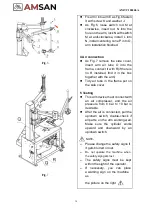

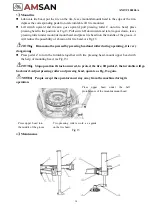

3.2 Mounting upper bead

⚫

Adjust relative position between the tire bead and

mount/demount head (the same as a mounting

bottom bead)

⚫

An optional lever is recommended to mount

low-profile and run-flat wheels. As Fig.16 the arrow

sign show, these parts can be installed onto the

mount/demount

head.

(Washer

on

the

mount/demount head should be replaced when this

optional lever is used.)

⚫

Pull back the pressing roller D to the position as Fig

15, pull down switch A and let the pressing roller

press tire bead into the groove, the roller I (on the

optional lever) also help to press the tire bead

ahead of mount/demount head 3cm as Fig.15.

⚫

Depress motor pedal and turntable rotate clockwise

at one circle till tire upper bead meets the rim,

mounting finished.

NOTE

:

➢

It is extremely important, for the correct

functioning of the machine, that when

demounting or mounting a tire, the chuck

rotates

in

a

clockwise

direction;

anticlockwise is only for correcting the wrong

operation.

➢

People except the operator must stay

away from the machine during its

operation

Optional lever with roller helps to press

(

Optional

)

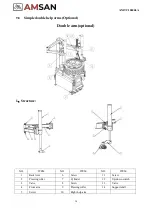

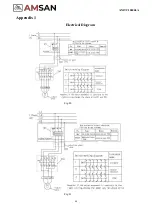

Summary of Contents for AM-TC10626LA

Page 1: ...PLEASE READ THE PRODUCT MANUAL ENTIRELY BEFORE INSTALLING OR OPERATING THE LIFT ...

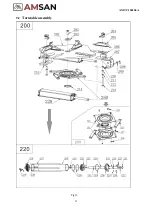

Page 22: ...Fig 34 21 AM TC10626LA 9 1 Column assembly 9 Exploded drawings ...

Page 23: ...Fig 35 22 AM TC10626LA 9 2 Turntable assembly ...

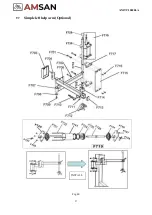

Page 24: ...Fig 36 22 AM TC10626LA 9 3 Gearbox motor assembly ...

Page 25: ...24 AM TC10626LA 9 4 Body assembly Fig 37 ...

Page 26: ...25 AM TC10626LA 9 5 Bead Breaker Cylinder Breaker Arm Assembly Fig 38 ...

Page 27: ...26 AM TC10626LA 9 6 Quick inflating system Optional Fig 39 ...

Page 28: ...27 AM TC10626LA 9 7 Simple left help arm Optional Fig 40 INSTALL ...

Page 41: ...40 AM TC10626LA Appendix 1 Electrical Diagram Fig 40 Fig 41 ...