22

Note:

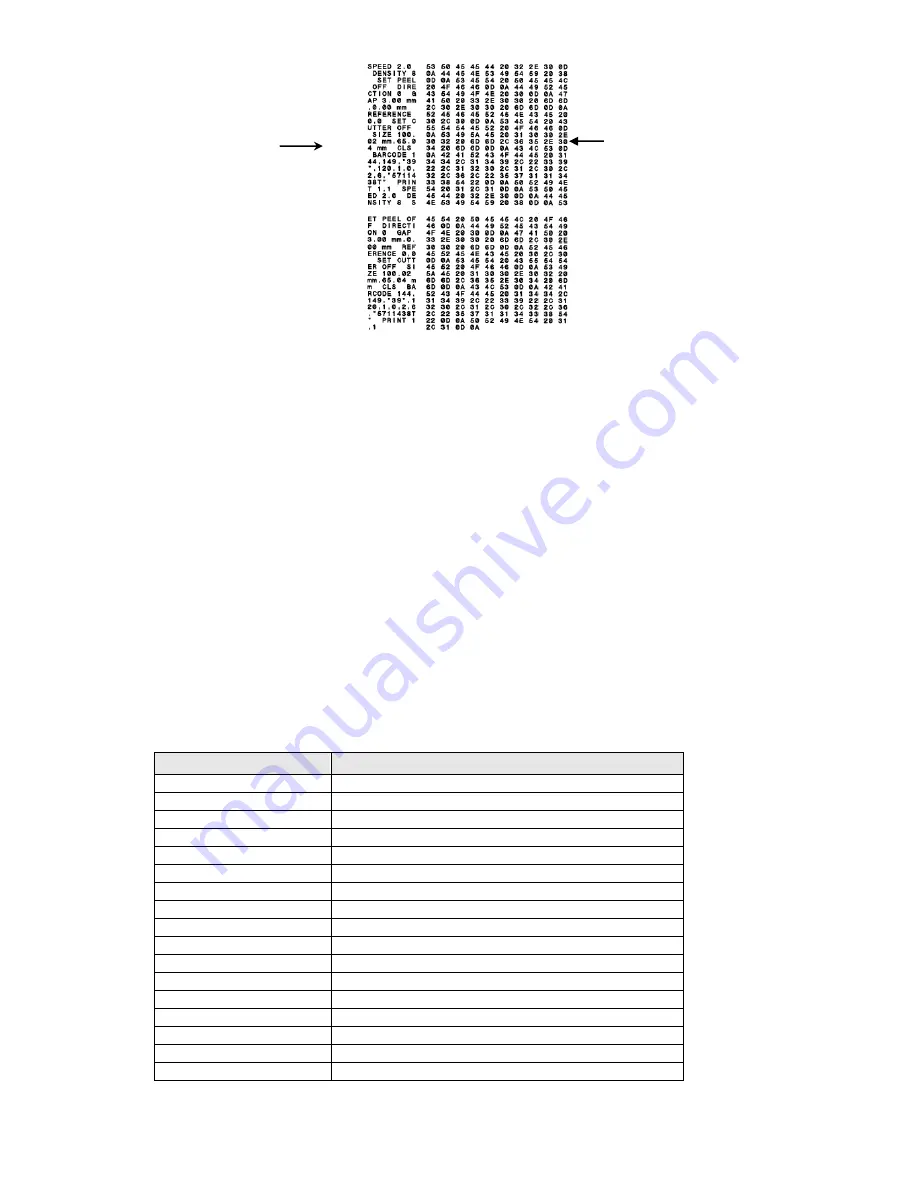

1. Dump mode requires 2

” wide paper width.

2. Turn off / on the power to resume printer for normal printing.

3. Press FEED button to back to the previous menu.

4.3.3 Printer Initialization

Printer initialization is used to clear DRAM and restore printer settings to defaults.

Printer initialization is activated by the following procedures.

1. Turn off the power switch.

2. Hold on the button then turn on the power switch.

3. Release the button when LED turns

green

after 5 amber blinks.

(Any green will do during the

5 blinks).

The LED color will be changed in the following order:

Amber

red (5 blinks)

amber (5 blinks)

green (5 blinks)

green/amber (5 blinks)

red/amber (5 blinks)

solid green

Printer configuration will be restore to defaults as below after initialization.

Parameter

Default setting

Speed

127 mm/sec (5 ips) (203DPI)

Density

8

Label Width

2

” (50.8 mm)

Label Height

4

” (101.6 mm)

Sensor Type

Gap sensor

Gap Setting

0.12” (3.0 mm)

Print Direction

0

Reference Point

0,0 (upper left corner)

Offset

0

Tear Mode

On

Peel off Mode

Off

Cutter Mode

Off

Serial Port Settings

9600 bps, none parity, 8 data bits, 1 stop bit

Code Page

850

Country Code

001

Clear Flash Memory

No

IP Address

DHCP

ASCII Data

Hex decimal data related to

left column of ASCII data