25

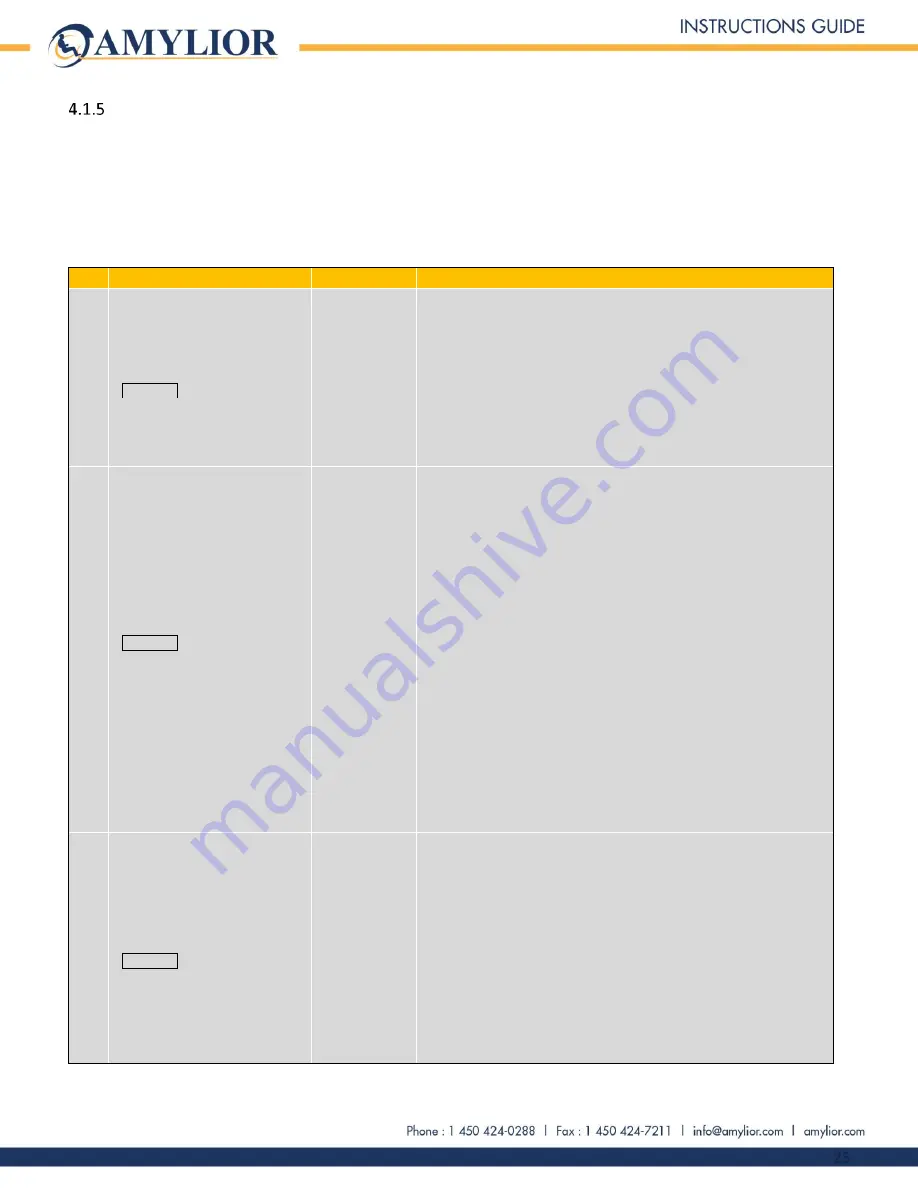

Additional symptoms table

The table below lists main symptoms for possible failures and troubleshooting methods to find the source of the

breakdown.

NOTE:

In the table below, checking or replacing a cable (actuator extension cable or R-Net cable) can be done

with

a temporary cable not belonging to the chair

. This makes it possible to verify whether the suspected faulty

cable is truly defective without wasting time in unnecessary disassembly.

Symptoms

Reason

Troubleshooting tips

A

−

Regardless of the chair’s power

options configuration, it refuses to

move forward or backward (Drive

Lock O

ut ‘DLO’

mode).

−

The “

red turtle

”

symbol flashes on

the joystick with color screen or the

yellow LED

on extreme left of speed

indicator flashes on the joystick with

LED display.

Note

: All power options are available

on the joystick.

The power

module jumper is

not connected

properly,

damaged or

missing

Verify that the jumper on the power module is properly connected and it is not

damaged. Replace jumper as required.

B

−

Regardless of the chair’s power

options configuration, it refuses to

move forward or backward (DLO

mode).

−

The “

red turtle

”

symbol flashes on

the joystick with color screen or the

yellow LED

on extreme left of speed

indicator flashes on the joystick with

LED display.

Note

: None of the power options are

available on the joystick.

The e-bx is not on

or not detected by

the R-Net power

module.

1.

Verify that the indicator light underneath the e-bx is constantly on or it is

flashing and that all power options are available on the joystick.

2.

If the e-

bx indicator light is off (or doesn’t flash) and the power options are

not available on the joystick, check that the 24 V power supply is reaching

the e-bx through contacts 1 & 4 of the R-Net bus cable

3.

If the 24 V power supply is getting to the e-bx and the connection between

the R-Net bus cable and the e-bx is good, replace the e-bx.

4.

If the 24 V power supply is not reaching the e-bx, verify that the R-Net bus

cables are properly connected from the power module to the e-bx. Check

for any damage. Replace defective or suspicious cables (with intermittent

contact).

5.

If the e-bx indicator light turns on and the power options are not available

on the joystick, verify that R-Net bus cables between the power module

and the e-bx are properly connected and in good condition. Replace

defective cables as required.

6.

If replacing R-Net bus cables and bus bar does not change anything, replace

the e-bx.

7.

If replacing the e-bx does not change anything, replace the R-Net joystick.

8.

If replacing the joystick does not change anything, replace the R-Net power

module.

C

−

Regardless of the chair’s power

options configuration, it refuses to

move forward or backward (DLO

mode).

−

The “

red turtle

”

symbol flashes on

the joystick with color screen or the

yellow LED

on extreme left of speed

indicator flashes on the joystick with

LED display.

Note

: All power options are available

on the joystick.

•

The tilt is lifted

over 15° (normal

operation)

•

E-bx controller

also thinks that

the tilt is lifted

over 15°.

For chairs with iQ Tilt Actuators (weight capacity of less than 450 lb / 205 kg) or

bariatric actuators (weight capacity between 450 lb and 550 lb / 205 kg and 250 kg

1.

Lower the tilt to its minimum position and check to see if the chair can

move forward or backward again.

2.

If the chair still does not move (DLO mode), take the following steps:

For an iQ Tilt Actuator

(Weight capacity of less than 450 lb / 205 kg)

a)

Access the First special boot-up mode.

b)

Completely forward retract the power recline. Make the tilt deploy to

its maximum position and retract back to its minimum position. If error

code #9661 appears on the joystick or this solves the problem, replace

the tilt actuator and its extension cable