34

*3-Button Remotes (315 MHz)

If provided with your garage door opener, the large

button is factory

programmed to operate it.

Additional buttons on any

Security

✚

®

3-button

remote or mini-remote can

be programmed to operate

other Security

✚

®

garage

door openers.

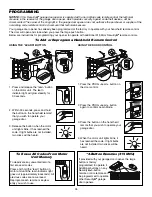

To Erase All Codes From Motor

Unit Memory

To deactivate any unwanted remote,

first erase all codes:

Press and hold the “learn” button on

motor unit until the learn indicator light

goes out (approximately 6 seconds). All

previous codes are now erased.

Reprogram each remote or keyless

entry you wish to use.

1. Press and release the “learn” button

on the motor unit. The learn

indicator light will glow steadily for

30 seconds.

2. Within 30 seconds, press and hold

the button on the hand-held remote*

that you wish to operate your

garage door.

3. Release the button when the motor

unit lights blink. It has learned the

code. If light bulbs are not installed,

two clicks will be heard.

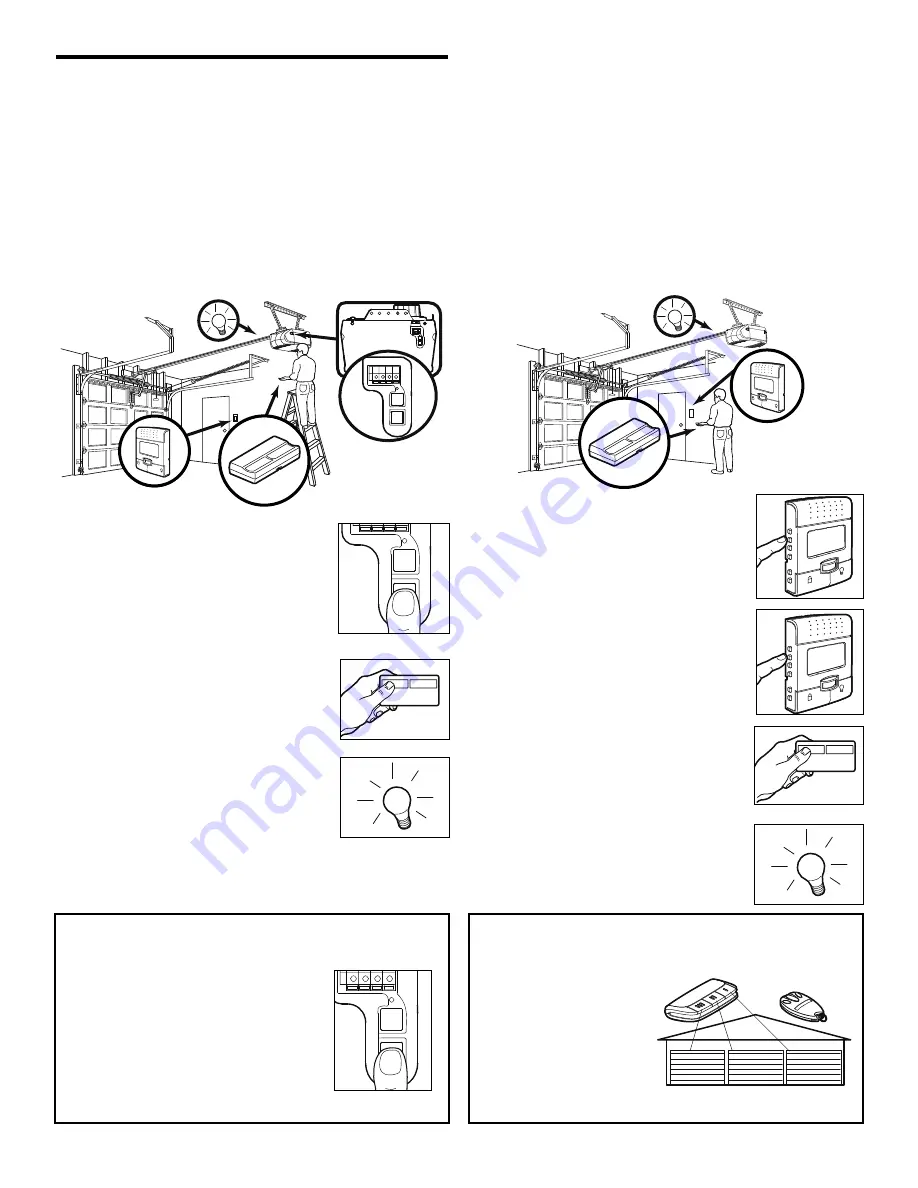

PROGRAMMING

NOTICE:

If this Security

✚

®

garage door opener is operated with a non-rolling code remote control, the technical

measure in the receiver of the garage door opener, which provides security against code-theft devices, will be

circumvented. The owner of the copyright in the garage door opener does not authorize the purchaser or supplier of the

non-rolling code remote control to circumvent that technical measure.

Your garage door opener has already been programmed at the factory to operate with your hand-held remote control.

The door will open and close when you press the large push button.

Below are instructions for programming your opener to operate with additional 315 MHz Security

✚

®

remote controls.

To Add or Reprogram a Hand-held Remote Control

USING THE “LEARN” BUTTON

USING THE DOOR CONTROL

1. Press the PROG <Learn> button on

the door control.

2. Press the PROG <Learn> button

again to confirm Learn Mode.

3. Press the button on the hand-held

remote that you wish to operate your

garage door.

4. When the motor unit lights blink, it

has learned the code. If light bulbs

are not installed, two clicks will be

heard.

LOCK

LIGHT

LOCK

LIGHT

Summary of Contents for Security+ 3850AD

Page 39: ...39 NOTES ...