17

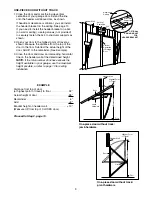

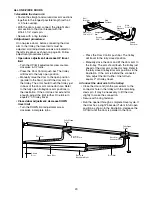

Invisible Light Beam

Protection Area

Sensor Beam

6" max.

above floor

Sensor Beam

6" max.

above floor

Facing the door from inside the garage

INSTALLATION STEP 10

Install The Protector System

®

The safety reversing sensor must be connected

and aligned correctly before the garage door

opener will move in the down direction.

IMPORTANT INFORMATION ABOUT

THE SAFETY REVERSING SENSOR

When properly connected and aligned, the sensor

will detect an obstacle in the path of its electronic

beam. The sending eye (with an orange indicator

light) transmits an invisible light beam to the

receiving eye (with a green indicator light). If an

obstruction breaks the light beam while the door is

closing, the door will stop and reverse to full open

position, and the opener lights will flash 10 times.

The units must be installed inside the garage so that

the sending and receiving eyes face each other

across the door, no more than 6" above the floor.

Either can be installed on the left or right of the door

as long as the sun never shines directly into the

receiving eye lens.

The mounting brackets are designed to clip onto the

track of sectional garage doors without additional

hardware.

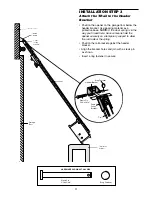

If it is necessary to mount the units on the wall, the

brackets must be securely fastened to a solid

surface such as the wall framing. Extension brackets

(see accessories) are available if needed. If

installing in masonry construction, add a piece of

wood at each location to avoid drilling extra holes in

masonry if repositioning is necessary.

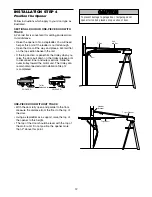

The invisible light beam path must be unobstructed.

No part of the garage door (or door tracks, springs,

hinges, rollers or other hardware) may interrupt the

beam while the door is closing.

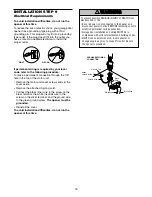

• Be sure power is not connected to the garage door

opener BEFORE installing the safety reversing sensor.

• To prevent SERIOUS INJURY or DEATH from a closing

garage door:

– Correctly connect and align the safety reversing

sensor. This required safety device MUST NOT be

disabled.

– Install the safety reversing sensor so beam is NO

HIGHER than 6" above garage floor.

WARNING

CAUTION

WARNING

WARNING