AD9776A/AD9778A/AD9779A

Rev. B | Page 41 of 56

Configuring PLL Band Select with Temperature Sensing

The following procedure outlines a method for setting the PLL

band select value for a device operating at a particular temperature

that holds for a change in ambient temperature over the total

−40°C to +85°C operating range of the device without further

user intervention. Note that REFCLK must be applied to the

device during this procedure.

1.

Program the values of N1 (Register 0x09, Bits[6:5]) and N2

(Register 0x09, Bits[4:3]), along with the PLL settings

shown in Table 22.

2.

Set the PLL band (Register 0x08, Bits[7:2]) to 63 to enable

PLL auto mode.

3.

Wait for the PLL_LOCK pin or the PLL lock indicator

(Register 0x00, Bit 1) to go high. This should occur

within 5 ms.

4.

Read back the 6-bit PLL band (Register 0x08, Bits[7:2]).

5.

Based on the temperature when the PLL auto band select is

performed, set the PLL band indicated in either Table 24 or

Table 25 by rewriting the readback values into the PLL

Band Select parameter (Register 0x08, Bits[7:2]).

This procedure requires temperature sensing upon start-up or

reset of the device to optimally choose the PLL band select

value that holds over the entire operating temperature range. If

the optimal band is in the range of 0 to 31 (lower VCO

frequency), refer to Table 24.

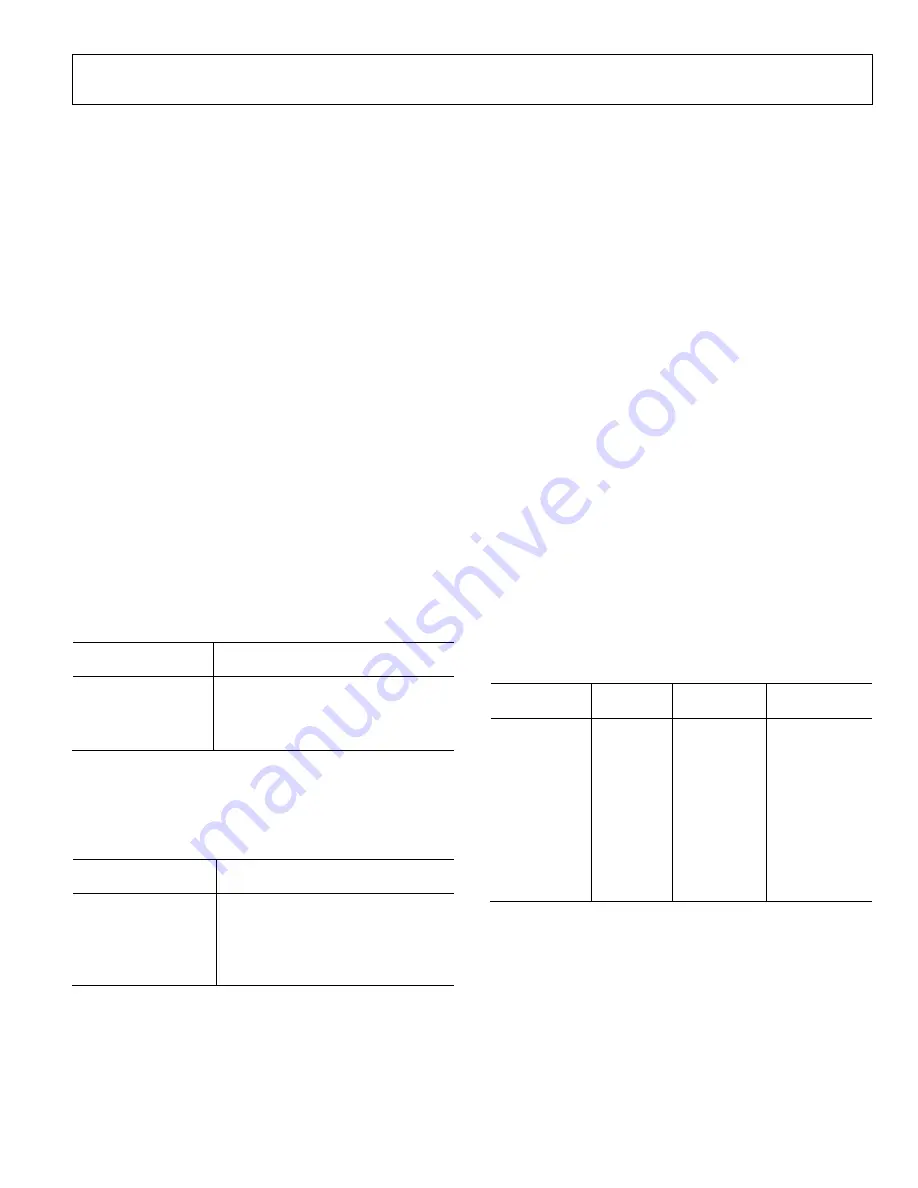

Table 24. Setting Optimal PLL Band, When Band Is in the

Lower Range (0 to 31)

If System Startup

Temperature Is

Set PLL Band as Follows

−40°C to −10°C

Set PLL band = readback band + 2

−10°C to +15°C

Set PLL band = readback band + 1

15°C to 55°C

Set PLL band = readback band

55°C to 85°C

Set PLL band = readback band − 1

If the optimal band is in the range of 32 to 62 (higher VCO

frequency), refer to Table 25.

Table 25. Setting Optimal PLL Band, When Band Is in the

Higher Range (32 to 62)

If System Startup

Temperature Is

Set PLL Band as Follows

−40°C to −30°C

Set PLL band = readback band + 3

−30°C to −10°C

Set PLL band = readback band + 2

−10°C to +15°C

Set PLL band = readback band + 1

15°C to 55°C

Set PLL band = readback band

55°C to 85°C

Set PLL band = readback band − 1

Known Temperature Calibration with Memory

If temperature sensing is not available in the system, a factory

calibration at a known temperature is another method for

guaranteeing lock over temperature. Factory calibration can be

performed as follows:

1.

Program the values of N1 (Register 0x09, Bits[6:5]) and N2

(Register 0x09, Bits[4:3]), along with the PLL settings

shown in Table 22.

2.

Set the PLL band (Register 0x08, Bits[7:2]) to 63 to enable

PLL auto mode.

3.

Wait for the PLL_LOCK pin or the PLL lock indicator

(Register 0x00, Bit 1) to go high. This should occur

within 5 ms.

4.

Read back the 6-bit PLL band (Register 0x08, Bits[7:2]).

5.

Based on the temperature when the PLL auto band select is

performed, store into nonvolatile memory the PLL band

indicated in either Table 24 or Table 25. On system power-

up or restart, load the stored PLL band value into the PLL

band select parameter (Register 0x08, Bits[7:2]).

Set-and-Forget Device Option

If the PLL band select configuration methods described in

the previous sections cannot be implemented in a particular

system, there may be a screened device option that can satisfy

the system requirements. This allows the user to preload a

specific PLL band select value for all devices that holds over

temperature. Example REFCLK and VCO frequencies are

shown in Table 26.

Table 26. Typical VCO Frequency Range vs.

PLL Band Select Value

f

REFCLK

(MHz)

f

VCO

(MHz)

Guaranteed

PLL Band

Total PLL

Divide Ratio

59.73335 955.7336

2

16

61.44 1966.08

61 32

67.2 1075.2

11 16

76.8 1228.8

20 16

80.01 1280

23 16

81.92 1310.72

25 16

92.16 1474.56

34 16

112.0 1792.0

50 16

119.4667 955.7336

2

8

122.88 1966.08

61

16