AD9776A/AD9778A/AD9779A

Rev. B | Page 48 of 56

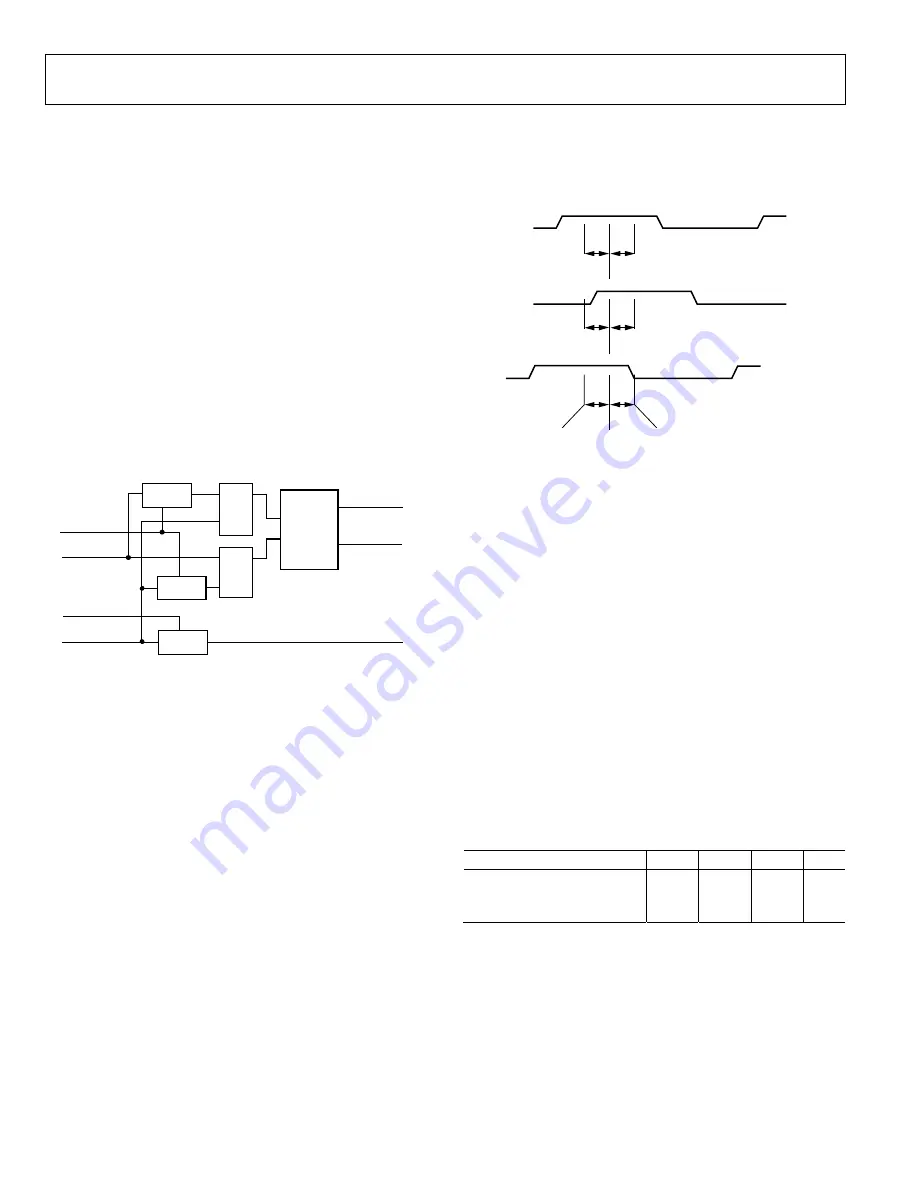

OPTIMIZING THE DATA INPUT TIMING

The AD9776A/AD9778A/AD9779A have on-chip circuitry that

enables the user to optimize the input data timing by adjusting

the relationship between the DATACLK output and DCLK_SMP

(the internal clock that samples the input data). This optimization

is made by a sequence of 3-wire interface register read and write

operations. The timing optimization can be done under strict

control of the user, or the device can be programmed to maintain a

configurable timing margin automatically. This function is only

available when the input data is referenced to the DATACLK

output. Each of these methods is detailed in the following section.

Figure 86 shows the circuitry that detects sample timing errors

and adjusts the data interface timing. The DCLK_SMP signal is

the internal clock used to latch the input data. Ultimately, it is

the rising edge of this signal that needs to be centered in the

valid sampling period of the input data. This is accomplished by

adjusting the time delay, t

D

, which changes the DATACLK

timing and, as a result, the arrival time of the input data with

respect to DCLK_SMP.

TIMING

ERROR IRQ

D

Q

Q

D

CLK

CLK

DCLK_SMP

PD1[0]

Δ

t

M

Δ

t

D

Δ

t

M

DATACLK

DELAY[3:0]

TIMING

MARGIN[3:0]

DATACLK

TIMING

ERROR TYPE

TIMING

ERROR

DETECTION

06

45

2-

4

02

Figure 86. Timing Error Detection and Optimization Circuitry

The error detect circuitry works by creating two sets of sampled

data (referred to as the margin test data) in addition to the

actual sampled data used in the device data path. One set of

sampled data is latched before the actual data sampling point.

The other set of sampled data is latched after the actual data

sampling point. If the margin test data match the actual data,

the sampling is considered valid and no error is declared. If

there is a mismatch between the actual data and the margin test

data, an error is declared.

The Data Timing Margin[3:0] variable determines how much

before and after the actual data sampling point the margin test

data are latched. Therefore, the data timing margin variable

determines how much setup and hold margin the interface

needs for the data timing error IRQ to remain inactive (show

error free operation). Therefore, the timing error IRQ is set

whenever the setup and hold margins drop below the Data

Timing Margin[3:0] value and does not necessarily indicate that

the data latched into the device is incorrect.

In addition to setting the data timing error IRQ, the data timing

error type bit is indicated when an error occurs. The data timing

error type bit is set low to indicate a hold error and high to

indicate a setup error. Figure 87 shows a timing diagram of the

data interface and the status of the data timing error type bit.

Δ

t

M

Δ

t

M

DATA

TIMING ERROR = 0

Δ

t

M

Δ

t

M

DATA

TIMING ERROR = 1

DATA TIMING ERROR TYPE = 1

Δ

t

M

Δ

t

M

DATA

DELAYED

DATA

SAMPLING

ACTUAL

SAMPLING

INSTANT

DELAYED

CLOCK

SAMPLING

TIMING ERROR = 1

DATA TIMING ERROR TYPE = 0

06

45

2-

4

03

Figure 87. Timing Diagram of Margin Test Data

Automatic Timing Optimization

When automatic timing optimization mode is enabled

(Register 0x03, Bit 7 = 1), the device continuously monitors

the data timing error IRQ and data timing error type bits. The

DATACLK Delay[3:0] is increased if a setup error is detected and

decreased if a hold error is detected. The value of the DATACLK

Delay[3:0] setting currently in use can be read back by the user.

Manual Timing Optimization

When the device is operating in manual timing optimization

mode (Register 0x03, Bit 7 = 0), the device does not alter the

DATACLK Delay[3:0] value from what is programmed by the

user. By default, the DATACLK delay enable bit is inactive. This

bit must be set high for the DATACLK Delay[3:0] value to be

realized. The delay (in absolute time) when programming

DATACLK delay between 00000 and 11111 varies from about

700 ps to about 6.5 ns. The typical delays per increment over

temperature are shown in Table 29.

Table 29. Data Delay Line Typical Delays Over Temperature

Delay

−40°C +25°C +85°C Unit

Zero Code Delay (Delay Upon

Enabling Delay Line)

630 700 740 ps

Average Unit Delay

175

190

210

ps

When the device is placed into manual mode, the error

checking logic is activated. If the IRQs are enabled, an interrupt

is generated if a setup/hold violation is detected. One error

check operation is performed per device configuration. Any

change to the Data Timing Margin[3:0] or DATACLK

Delay[3:0] values triggers a new error check operation.