Summary of Contents for Zitzi Guppy G2

Page 1: ...User manual Zitzi Guppy G2 EN ver 2 0 2020 04 15 ...

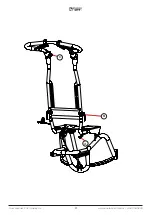

Page 9: ...9 User manual Zitzi Guppy G2 www anatomicsitt com 46 11 16 18 00 D B A C ...

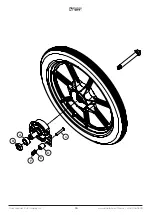

Page 11: ...11 User manual Zitzi Guppy G2 www anatomicsitt com 46 11 16 18 00 A B C ...

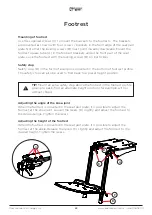

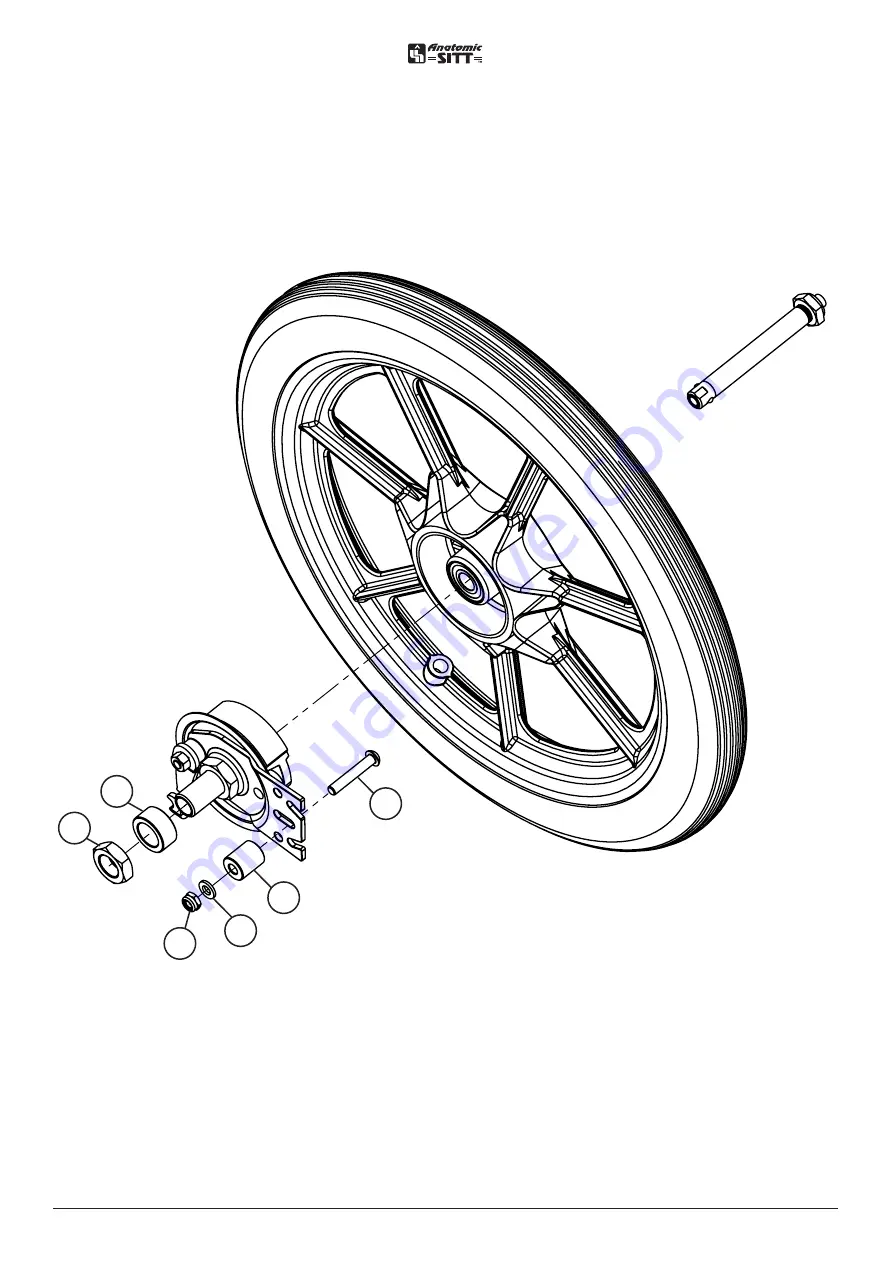

Page 19: ...19 User manual Zitzi Guppy G2 www anatomicsitt com 46 11 16 18 00 C A B F E D ...