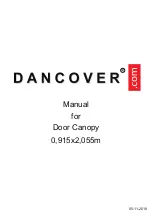

10

Using the method shown, you should be able to install the NAVI-

TRAC LT using only one NAVI-TRAC JACK.

You will lift one side of the Hip End and insert and pin the

Uprights onto the under fitting of each weldment. Then, move the

jack to the opposite side and install the remaining Uprights.

NOTE: To achieve proper balance, the NAVI-TRAC JACK

should be positioned 1 ft off center on the side Eave Bar (E-

15) in the direction of the peak of the frame (see fig. 22).

Be

attentive to the balance of the frame should uneven terrain require

a slight shifting of this balance point.

INSTALLING UPRIGHTS UNDER

THE UPPER HIP FRAME.

Use the NAVI-TRAC JACK at 1 ft off-center of

the Eave Bar (in the direction of the peak) to lift

one side of the hip end upper frame. Insert the

uprights onto the bottom fitting of each weldment

and secure horizontally with a short pin.

Repeat this procedure on the opposite side

Eave Bar (again 1 ft off-center in the direc-

tion of the peak), and install the opposite side

Uprights.

To install an upright under the Eave Weldment

on the end eave, simply use a Lifting Cradle to

lift the Eave as shown.

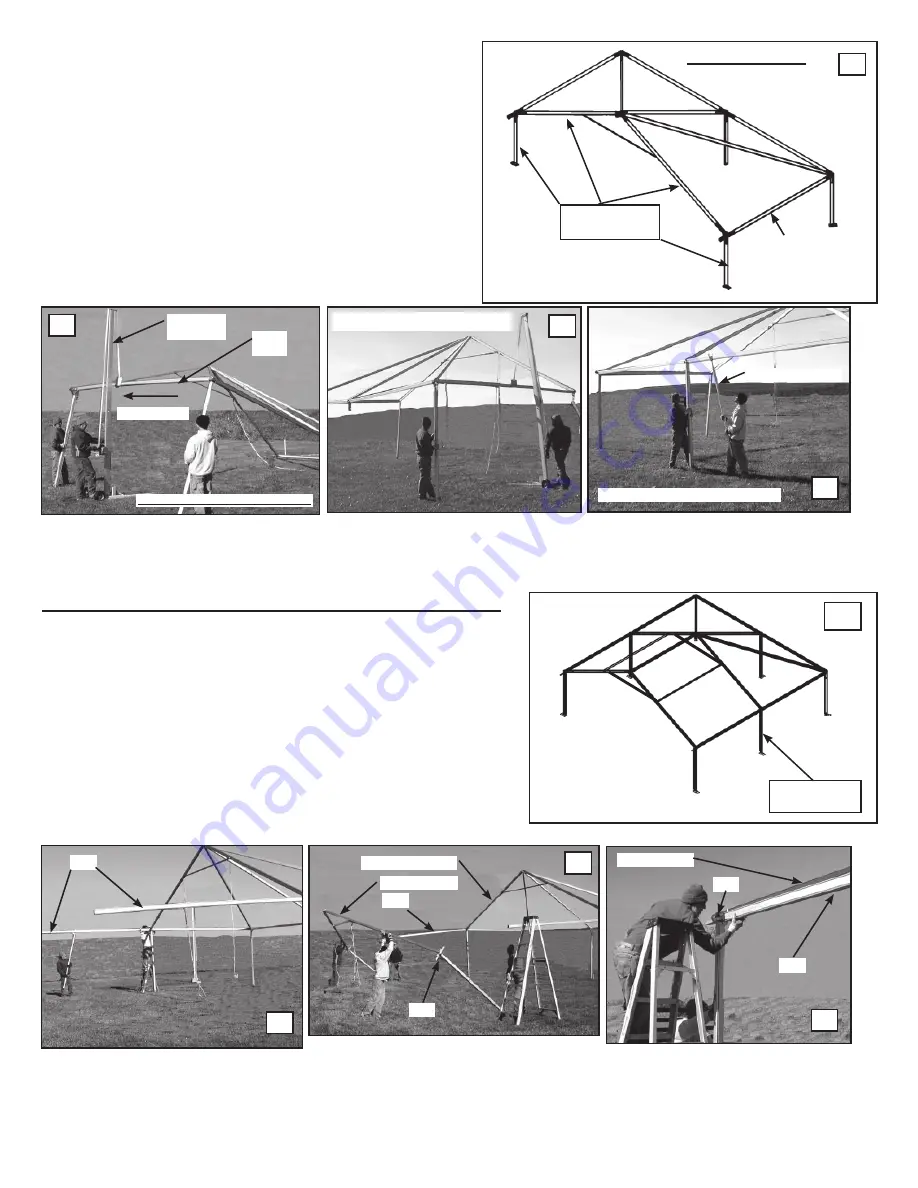

ADDING MIDDLE BAYS TO FORM A RECTANGULAR UNIT

The NAVI-TRAC LT hip end unit can be extended into a rectangle by adding

parallel middle bays as shown (fig. 25).

Each middle beam is constructed the same as the hip end cross beam, except

that uprights are attached before standing the beam to vertical. Also, the con-

necting parts (Ridge, Eaves, etc) are first installed on the standing beam, and

the new middle beam is stood and then joined to them in the air.

Unlimited middle bays can be added, but when the unit exceeds 60’ in length,

and for each each additional 60’ of overall length, an X-cabled bay must be

included (see Appendix 1, fig. 57 & 58 for a description of the X-cabling).

This assembly section describes units with hip ends on both ends of the unit.

(For hip end-gabled end or purely gabled end units, see Appendix 1).

Install Eave Bars (E-15) to the Eave Weldments

of the standing beam. Let the Eave Bars simply

hang in a horizontal position as shown above.

. Construct the add-on beamwith uprights attached

and pivot it to vertical as shown above.

Note: work-

ers must “foot” the baseplates to prevent the

baseplates from sliding out.

Secure the new middle beam by attach-

ing the Eave Bars (E-15) from the standing

beam to the mid beam’s Eave Weldment as

shown above.

NAVI-TRAC

JACK

E-15

(SIDE)

INSTALLING UPRIGHTS (1st SIDE)

INSTALLING UPRIGHTS (2nd SIDE)

INSTALLING UPRIGHT @ MID EAVE

LIFTING CRADLE

E-15

MIDDLE BEAM

HIP CROSS BEAM

E-15

E-15

MIDDLE BEAM

EW

EW

21

22

23

24

25

26

27

28

HIP END FRAME

HIP END

CROSS BEAM

OFF-CENTER

HIP END

CROSS BEAM

E-15

(SIDE)