7

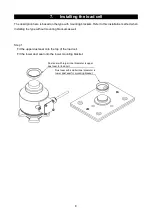

6. About the mounting brackets

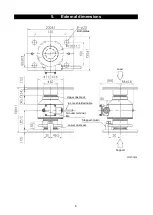

When manufacturing the mounting brackets, make the guide holes of the bearing plates to which load is

applied and the stopper column are of the dimensions shown below. The hardness of the bearing plate

and stopper column should be HRC 32~38.

The fastening bolts used for mounting the stopper column are as follows.

Fastening bolts: M12 hex bolts (Tensile strength class: 10.9)

Recommended tightening torque: 76 Nm

Attach the stopper column at a position 50 mm from the center, referring to the figure below.

Unit: mm

Taper angle

Lower bearing plate

Upper bearing plate

Stopper column

Direction where fluctuation

distance is large

(Example: Travel direction of truck)

Stopper column mounting

hole (M12)

Lower bearing

plate

Stopper column mounting position

26 or

mor

e

Taper angle

26 or

mor

e

15°

15°