5

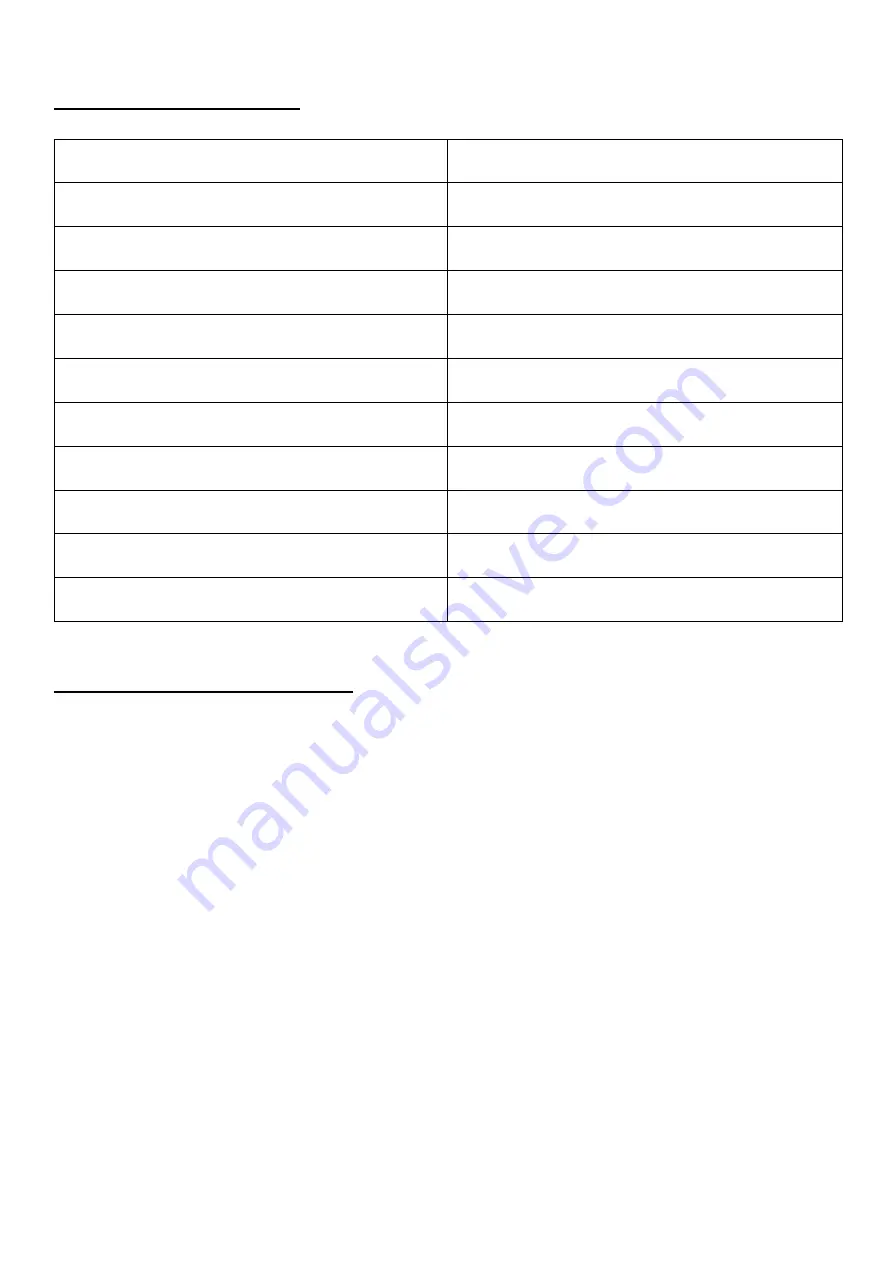

3. Technical specifications

Maximum flow (Free Discharge)

280 m

3

/h (78 l/sec)

Low and Medium flow and optional sensor inputs

0-100% adjustable on each speed.

Set on installation

Dimensions (w x h x d) [mm]

560 x 635 x 260

Spigot diameter [mm]

Ø125

External diameter condensate discharge [mm]

22

Filter class

EU3

Weight

14 kg

Supply voltage [V~/Hz]

230 / 50Hz / 1Ph

Power (Watts)

Maximum 150W

Protection degree

IPX2

Thermal efficiency up to %

91%

4. Fitting the DC MVHR unit in brief

Please ensure that you read each section of this leaflet carefully. This section is just a brief overview of each

installation stage.

1. Dismantle the DC MVHR unit in accordance with the diagram and text on page 6.

2. Mounting plate: Mounted by means of stand off feet, screws and plugs supplied, vertically or horizontally. Use the

drilling template on the side of the box to locate the hole positions, ensuring that there is enough space around the

unit so that the duct work and the condensation drain can be fitted (see pages 7 & 8 for details of which side of the

unit the condensate drain should be fitted).

3. Reassemble the DC MVHR unit in accordance with the diagram and text on page 6.

4. When the HR unit has been installed, the ducting can be completed. Remember that both ducts to and from the

outside will be fitted to one side of the unit and the ducts to and from the home are attached to the other side of the

unit refer to (page 9).

5. When the duct runs are completed, and an appropriate electrical supply is present see page 10 for wiring details,

the installation can be completed.

For further information about the operation, adjustment and maintenance of the unit, read the

following pages carefully.