PRODUCT MANUAL

68/72ST Above Deck Compact Motor

™

10

STEP 4

Install motor unit.

Having a second person to assist during this step may help to avoid fouling the wiring and drain tube with sealant as they are

passed through the deck.

4.1 Apply sealant to the deck to prevent water ingress. In addition to sealing the mounting holes, apply a bead of sealant

around the perimeter of the base to form a completely watertight seal.

NOTE: For mounting on metal surfaces, the base must also be completely isolated from the mounting surface to prevent

galvanic corrosion.

4.2 Fit the motor unit [1] to the deck using the appropriate length ISO 4017-A4 M10 or 3/8” bolts, large washers or backing

plate, and locking nuts.

4.3 Place the stainless steel cover [2] back on the motor unit and slide it down into position.

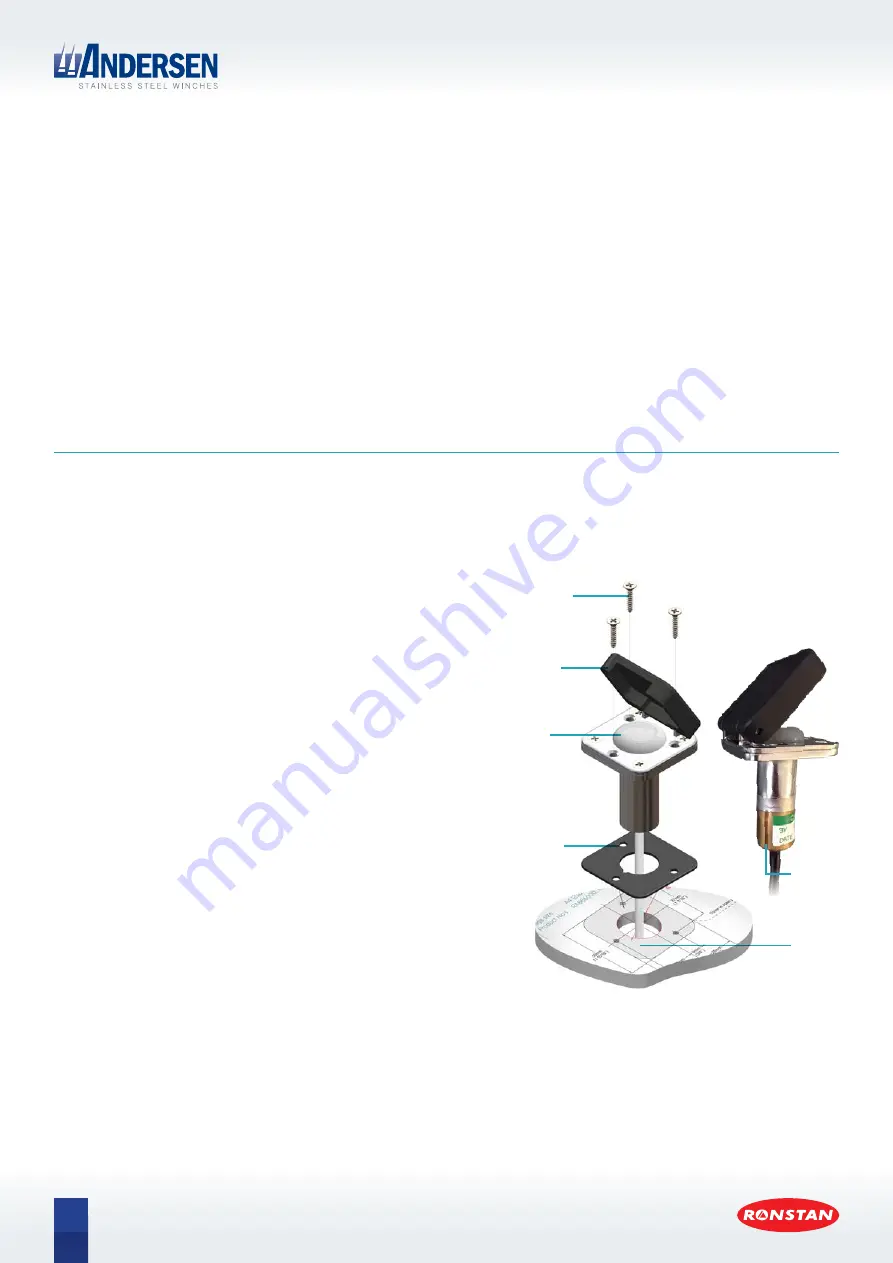

STEP 5

Install push buttons

The push buttons [A1] require 50mm clearance depth below the

mounting surface. They are supplied with a short 190mm (7 1/2”)

cable lead; each is connected below deck to a 1000mm (39”) long

control cable [A12] and then to one of the short cable leads from the

motor. Extension cables are available and may be ordered separately

if necessary.

5.1 Select the desired location. For safety reasons it is recommended

that the push buttons [A1] are located in close proximity to the

winch, preferably within reach.

5.2 Determine the preferred orientation of the hinged covers (on

vertical surfaces it should open upwards). Then using the drilling

template or the rubber gasket [A2] as a guide, drill a Ø25mm (1”)

hole.

5.3 Drill a 3mm (1/8”) hole in each of the mounting screw locations.

5.4 Fit gaskets and push buttons in place. Secure the push button

units with the M4x20mm self tapping screws [A10], using a small

amount of sealant at each hole.

5.5 Ensure that the breather channel on the side of the through-deck

tube of the push button is clear and free of dirt or sealant.

Breather

channel

Drilling

template

Mounting

screws

Hinged

cover

Push

button

Rubber

gasket

Push button installation