Bulletin II-102051-EN • Revision B

November-2007

19

#!

$

%

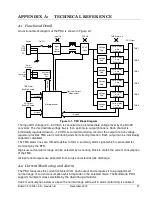

Because the PDU supplies and monitors the entire TMA system, all system components should be

considered when troubleshooting. The TMA system can include TMA, Bias Tee, surge arrestor,

diplexer (crossband coupler), and other devices in addition to RF and DC cables and connectors as

well as the PDU itself.

1

"

5 +

:

,

A digital instrument is preferred, capable of measuring DC voltage, current, and resistance. When

measuring current, use an unfused high-current input if a short circuit is suspected. For more

accurate current consumption measurement, use a low-current input and suitable measuring range.

3

. ,

A frequency-sweep instrument incorporating detector and tracking generator should be able to

display return loss or VSWR at the operating frequencies of the TMA system. Always calibrate

before measuring for best accuracy. Use Distance-to-Fault (DTF) measurement judiciously as

results can be difficult to interpret due to the bandwidth limitation of the TMA.

1

(

26

Problems occurring the first time the TMA system is operated are often due to installation errors and

oversights. Be sure to check all RF and DC connections, switch and shunting block settings. The

check lists in this section may be helpful.

•

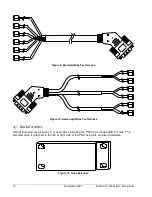

Check labeled or embossed port designators to ensure the BTS/Node-B port is connected to the

feeder and the ANT port to the antenna.

•

Some TMAs with more than one BTS/Node-B port accept DC supply on specific port(s) only.

•

Tower-top jumpers may be mislabeled or cross-connected.

•

Verify operating bands of TMA and antenna if high VSWR appears.

•

Uplink band VSWR may be degraded if the TMA is measured without DC supply.

•

The TMA, when detecting a malfunction in its circuitry, will raise or lower its current consumption

to a value outside the PDU normal current range in order to report the TMA fault. This will lead to

an alarm indication from the PDU.

•

A TMA equipped with VSWR detector will report a fault when the measured VSWR exceeds the

programmed limit. The VSWR detector requires TX power for its operation. Therefore, this type

of fault indication will clear if all transmitters in that RF path are turned off.

•

RF and DC operation of the TMA can be verified on the ground using a short jumper and known

good termination load as needed.

#+

•

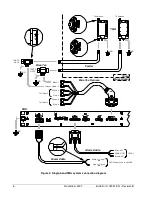

The Bias Tee ANT port must be connected in the direction of the tower feeder, not the base

station. Connector genders vary by model.

•

Ensure the Bias Tee is installed on the same feeder as the TMA.

•

Verify that any Surge Arrestor in the path between the Bias Tee and TMA is only of the DC

passing type.

•

Ensure there are no other devices in the path that inject, block, or shunt DC voltage.

•

Verify the Bias Tee operating band if high VSWR appears.

Summary of Contents for Multimode Power Distribution Unit

Page 1: ...Installation and Operation User Guide...

Page 2: ......

Page 4: ...iv November 2007 Bulletin II 102051 EN Revision B 0 1...

Page 31: ......