ANDREWS COMBIfl o

47

GB

5.2.4 HEAT ENGINE THREE (BOTTOM UNIT) COMMISSIONING FOR 150 MODEL ONLY

20. Carefully disconnect the fan power connector from heat engine two and replace the fan power connector

from heat engine three (see point 4 illustration).

21. Ensure that the DHW tank temperature is below 45

O

C. Drawer off water until the tank temperature is

below this value. The temperature can be checked on the home page of the appliance display (see point

14)

22. Press the appliance reset button (on the left hand side) for approximately one second. The heat engine

lockouts from the previous heat engine commissioning should now be cleared.

23. Using the display, select the hot water page and turn on DHW (see point 14)

24. Allow three minutes for the heat engine to warm up fully before checking the combustion.

25. Ensuring that the DHW tank temperature remains below 45

O

C during the commissioning process, if

necessary opening taps to bring the temperature down. The CO

2

combustion fi gure should be 9.2% +/-

0.1%. Typical expected valves for CO will be between 130ppm and 180ppm (but may be higher during

initial operation).

If you are experiencing CO readings that exceed 250ppm after 30 minutes of burner operation,

please fi rst check that your gas analyser is functioning correctly and then contact Andrews Water

Heaters on the customer support number given on the rear cover of this manual, for advice

.

26. If adjustment is required, remove dust cover of gas valve throttle adjustment screw and insert a 4mm

allen key or medium fl at blade screw driver to adjust (see point 8).

27. When adjustments are complete, turn off DHW (see point 14) and wait for appliance to stop before

proceeding

5.2.5 HEAT ENGINE COMMISSIONING COMPLETION

28. Replace all fan power connectors

29. Replace all throttle adjustment screw covers

30. Press the appliance reset button (on the left hand side) for approximately one second. The heat engine

lockouts from the previous heat engine commissioning should now be cleared.

31. Ensure that the DHW tank temperature is below 45

O

C. Drawer off water until the tank temperature is

below this value. The temperature can be checked on the home page of the appliance display.

32. Turn off all taps.

33. Using the display, select the hot water page and turn on DHW. Set the DHW temperature to 60

O

C.

34. Allow fi ve minutes for all the heat engines to activate and warm up fully before checking the combustion

and checking the gas rating.

35. With the DHW tank temperature below 50

O

C (see point 3) check the overall CO

2

combustion fi gure,

which should be in the range 9.1% to 9.6%. Also check that CO does not exceed 250ppm (typical

expected valves will be between 130ppm and 180ppm) at any time during this commissioning operation.

36. With the DHW tank temperature remaining below 50

O

C (all heat engines will be operating at full load)

check the gas consumption rate at the meter, with only this appliance in operation. The gas consumption

should be within 5% of the data plate gross kW input value. Compare the gas consumption rate at the

meter against the following table:

37. With all the heat engines in operation, continue to allow the DHW tank temperature to rise towards the

set-point and monitor the CO

2

and CO up until the set-point is reached (this should take around 5 - 8

minutes, depending on current DHW tank temperature). During the last 2

O

C before DHW set-point is

reached, all the heat engines will typically be operating at their minimum modulation level.

CO

2

levels at minimum modulation level should typically be between 8.4% and 9.0% and CO levels

(except immediately after ignition) should not exceed 200ppm.

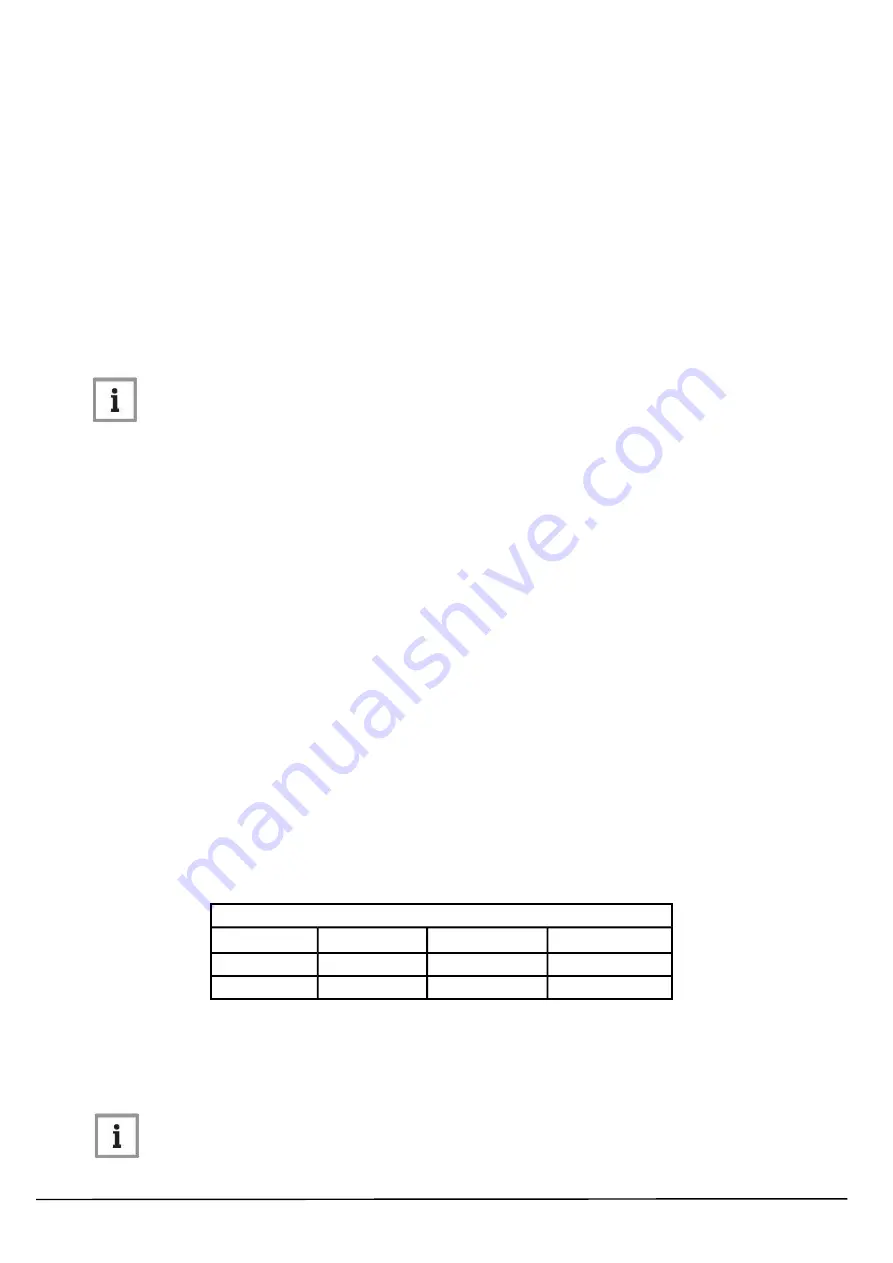

G20 Rating Table

(1040 Btu/ft³) (38.8 MJ/m³)

gross kW input

gross

Btu/h input

ft³ per min

m³ in 2 mins

102

348,271

5.6

0.32

152

518,992

8.4

0.48

Summary of Contents for COMBIflo 100/300

Page 9: ...ANDREWS COMBIflo 7 GB 3 1 GENERAL DIMENSIONS CONNECTIONS 3 0 TECHNICAL DATA ...

Page 12: ...ANDREWS COMBIflo 10 GB 3 4 APPLICATION EXAMPLES Single Heating Circuit Simple ...

Page 13: ...ANDREWS COMBIflo 11 GB Single Heating Circuit Immersion DHW Circulation pump ...

Page 16: ...ANDREWS COMBIflo 14 GB Heating Circuit External 0 10V control ...

Page 17: ...ANDREWS COMBIflo 15 GB BMS INTERNET CONNECTIONS ...

Page 18: ...ANDREWS COMBIflo 16 GB 3 5 WIRING DIAGRAMS PCB 1 ...

Page 19: ...ANDREWS COMBIflo 17 GB PCB 2 3 ...