Summary of Contents for RFF 13/175

Page 8: ...8 Blank Page Issue 4 21042018 ...

Page 19: ...3 11 Wiring Diagram 19 Issue 4 21042018 ...

Page 50: ...8 Parts List 8 1 General Assembly 50 Issue 4 21042018 ...

Page 51: ...51 Issue 4 21042018 ...

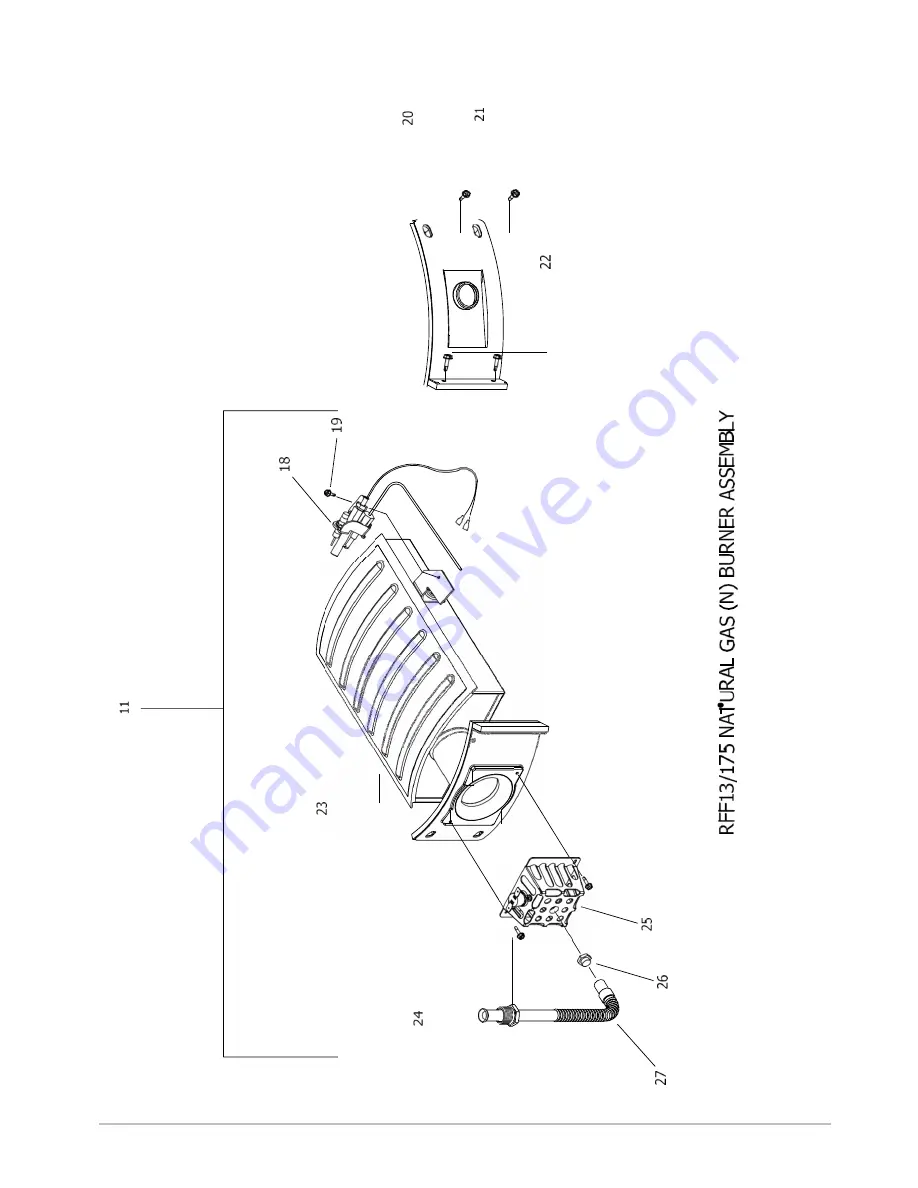

Page 52: ...52 Issue 4 21042018 ...

Page 53: ...53 Issue 4 21042018 ...

Page 54: ...8 2 Control Box Assembly 54 Issue 4 21042018 ...