10

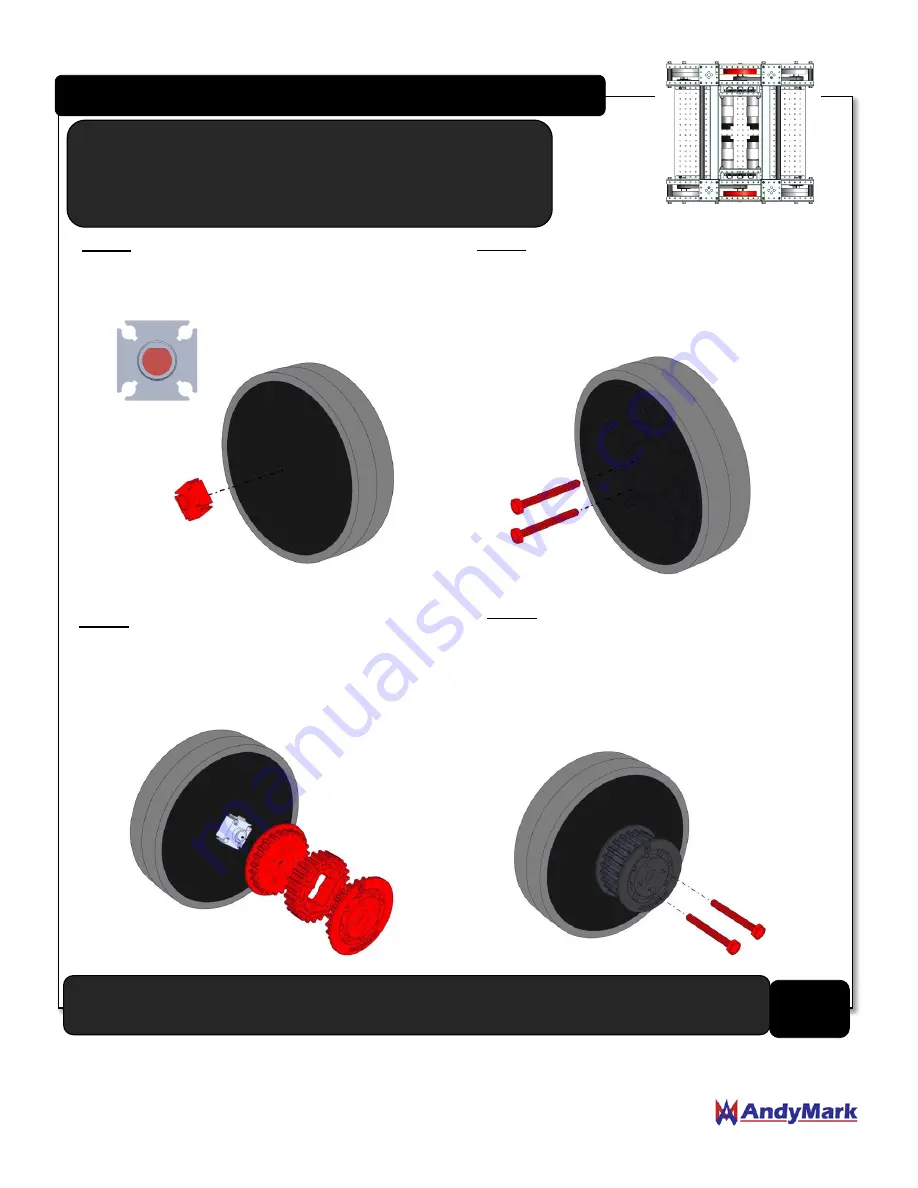

Center Wheel Assembly Instructions (QTY 2)

Step 1:

Place a 6mm D-Bore Double Boss Nub

(am-3215a) into the center bore of a 4" 8mm

Bore Wheel on the flat side of the wheel.

Step 2:

Flip the wheel over and secure the

Nub to the wheel by threading two 6-32 x

1.25 in Hex Head Screws (am-1437) into

the Nub. Be sure to place the 6-32 screws

in opposite holes of the wheels.

Step 3:

Place a 24 Tooth HTD Pulley Extender

(am-3404) between two 24 Tooth HTD Pulley

Halves (am-3401_half), and place all three

components onto the boss of the Nub.

2X

Step 4:

Align the bolt circles of the Nub and the

Pulley Assembly, and secure the pulley by

threading two 6-32 x 1.25 in Hex Head Screws

(am-1437) into the Nub. Be sure to thread the

screws into the opposite holes that were used to

secure the Nub to the Wheel.

Repeat one more time to make 2 total Center Wheel Assemblies.

NOTE: This subassembly applies to any 6WD TileRunner

configuration utilizing a Stealth, Performance, or

Compliant Wheel as the center wheel. See Page 20 for

Performance Wheel Assembly Instructions.