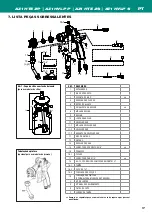

4

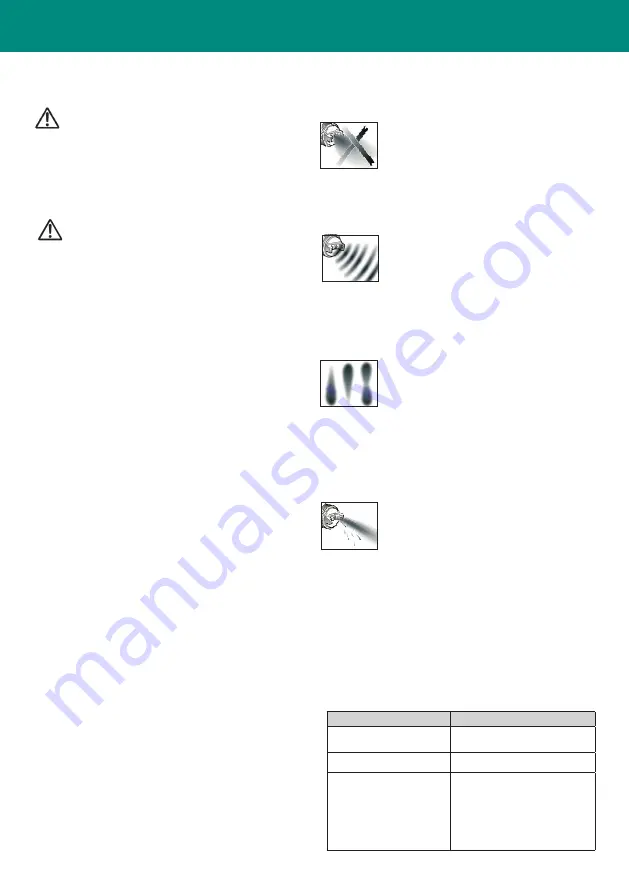

6. TROUBLESHOOTING

GUN DOES NOT SPRAY

- Fluid adj. knob (6) closed.

Check and adjust.

- Tip hole of nozzle (2) obstructed. Check and clean.

- Paint filter obstructed.

Check and clean.

- Non drip obstructed.

Check and clean.

INTERMITTENT SPRAY PATTERN

- Air escapes from fluid nozzle.

Check , clean & replace if

necessary.

- Air escapes from fluid needle

Tighten.

packing (10).

- Air escapes from cup joint.

Tighten.

- Dirt inside air cap (1).

Clean.

DEFECTIVE SPRAY PATTERN

- Dirty nozzle (2) or air cap (1).

Clean carefully.

- Nozzle (2) or air cap (1)

Replace if damaged.

has been damaged.

- Fluid nozzle (2) is loose.

Tighten.

- Paint viscosity too high or

Dilute paint or increase

too low.

viscosity

- Fluid output too high or

Adjust fluid adj. knob (6)

too low.

to reduce or increase.

LEAKING

- Fluid nozzle (2), needle set

Clean or replace if neces-

(9) or gun body, dirty,

sary.

damaged or worn on seat.

- Dirt inside air cap (1).

Clean.

- Loose fluid adj. knob (6).

Adjust.

- Fluid needle spring (8) is

Replace.

worn.

- Loose fluid nozzle (2).

Tighten.

- Needle packing set (10) loose, Adjust, clean or replace.

too tight, dirty or worn.

AIR ESCAPES FROM AIR CAP

- Air valve (11-2), air valve

Clean or replace if neces-

seat (11-3) or air valve spring sary.

(11-1) dirty or damaged.

6.1 INSPECTION & REPLACEMENT STANDARD

EN

AZ1 HTE 2P | AZ1 HVLP P | AZ1 HTE 2S | AZ1 HVLP S

5. MAINTENANCE AND INSPECTION

CAUTION

- Never use spare parts that are not AIRGUNSA originals.

- Never damage fluid nozzle tip, fluid needle or air cap holes.

- Never immerse the spray gun completely in liquids such as thinner.

5.1 CLEANING PROCEDURE

- Never soak air cap set (1) in cleaning liquid for an extended period,

even when cleaning.

- Never use metal brush to clean the gun.

1. Clean fluid passages and air cap set (1). Spray a small amount of cleaner

to clean fluid passages.

2. Clean each section with brush soaked with cleaner and wipe out with

waste cloth.

Do not immerse the whole gun in the cleaner. If done, it can

damage parts. When cleaning, never scratch any holes of air cap set, fluid

nozzle, or fluid needle set.

5.2 MAINTENANCE

BEFORE DISASSEMBLY, CLEAN FLUID PASSAGES.

a.

Disassemble fluid nozzle (2), while keeping fluid needle (9) pulled (triggering)

in order to protect its seat section.

b.

Disassemble fluid needle set (9).

(only when strictly necessary).

c.

Remove the fluid adj. knob (6) and needle spring (8), extracting the spring and

fluid needle set (9), from the back of fluid adj. guide (7) set still assembled on

the gun body.

d.

Adjustment of the needle packing set, must always be carried out with fluid

needle (9) still assembled, tightening the nut with a properly spanner, making

sure that excessive tightening does not impede movement of fluid needle (9),

resulting in paint leaking from fluid nozzle tip (2).

- When you remove needle packing nut (10), don’t leave the plastic part of

needle packing set in the gun body.

- Try to adjust it carefully while pulling trigger and confirming movement of fluid

needle set (9).

- If you tighten it too much, repeat operation.

e. Disassembly of pattern adjustment set (5) and/or air adjustment set (14).

In order to disassemble pattern adj. set (5) and/or air adj. set (14), turn

manually turn the hexagon knob of the adjustment counter-clockwise to

open it completely and unscrew the hexagon face with a spanner turning it

counter-clockwise.

- To reassemble pattern adjustment set (5) and/or air adjustment set (14),

reverse the procedure.

IMPORTANT: Before reassembling pattern adjustment set and/or air

adjustment set, make sure that these operations are carried out with the

adjustment fully open.

The fluid passages of the gun, must be cleaned thoroughly

after each use, especially after use with bi-component paints.

Incomplete cleaning can cause defective pattern shape.

Before carrying out maintenance and inspection ALWAYS

observe warning indications.

WHERE TO INSPECT

REPLACEMENT PART

a. Each hole passage of air cap

(1) and fluid nozzle (2).

Replace if it is crushed or deformed.

b. Packing and O ring

Replace if it is deformed or worn out.

c. Leakage from seat section

between fluid nozzle (2) and

fluid needle set (9).

Replace them if leakage does not stop

after fully cleaning fluid nozzle (2) and

fluid needle set (9).

If you replace fluid nozzle (2) or fluid

needle set (9) only, fully matchthem and

confirm that there is no leakage.