- 10 -

3. Painting job

3-1 Connect fluid hose.

Securely connect fluid hose. W hen paint leaks, never try to stop it by

hand / In that case, stop pump immediately and reduce paint pressure

down to 0 pressure .

Be sure to use air hose with built-in ground wire or fluid hose with built-in

ground wire or use grounded gun stay in order to connect ground.

Before using a new airless spray gun, clean inside of the new airless spray

gun. If not, rust preventive inside airless spray gun can cause painting

failure.

H I N T

!

Use tip filter set when you use paint with lots of pigments, which are likely to

clog (tip filter set is optional).

For general painting conditions, paint gun perpendicularly against painting

surface and keep painting distance at about 30 - 50 cm between nozzle tip of

gun and painting surface. (It differs depending on each condition).

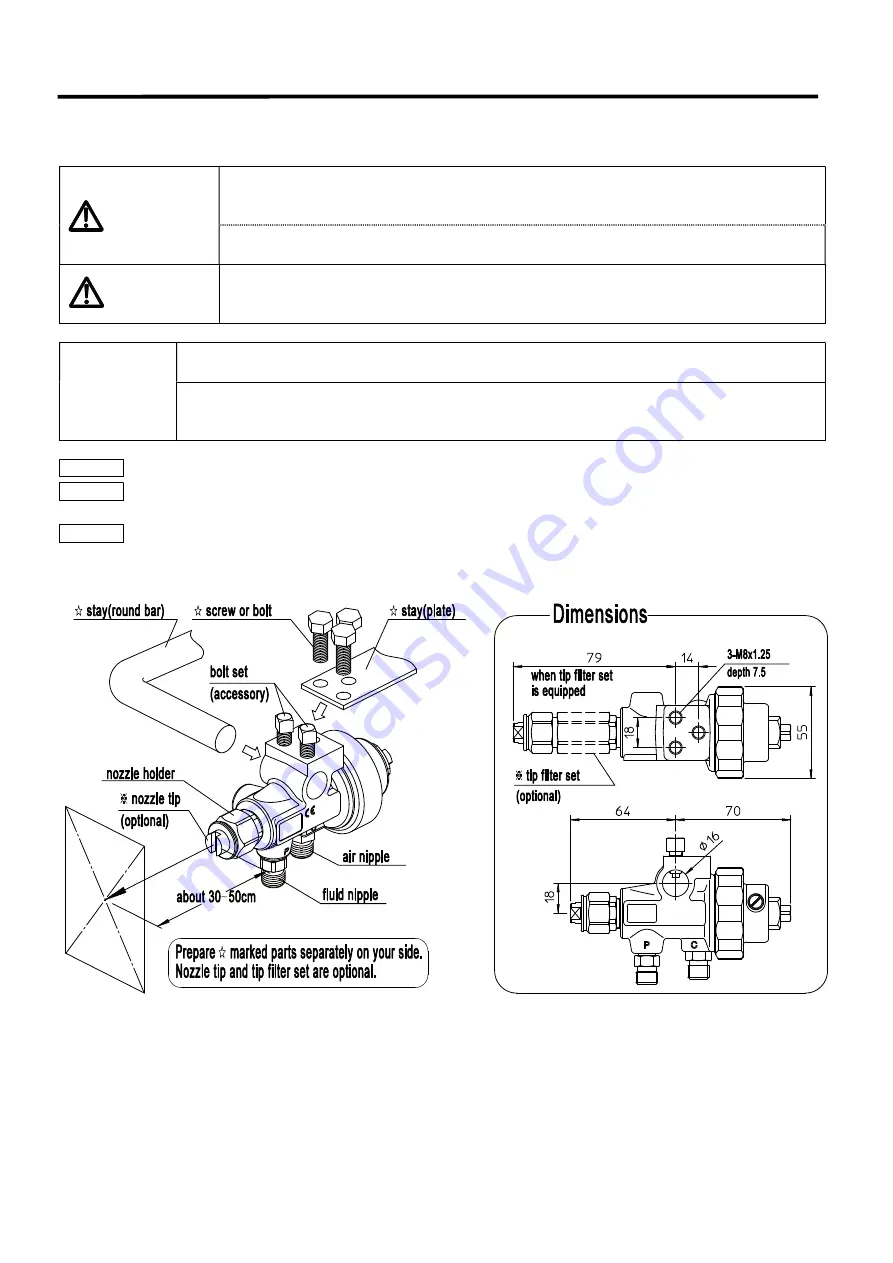

job 1

Fit airless automatic spray gun to stay

(round bar or plate)

and fix it in painting direction.

job 2

Remove nozzle holder and fit nozzle tip. (Refer to item 4 on page 4 selection of nozzle

tip according to paint to be used).

job 3

Connect operating air hose to air nipple (C engraved side for operating air), and nylon

(fluid) hose to fluid nipple (P engraved side for fluid.).

WARNING

CAUTION

Summary of Contents for AL-96

Page 1: ...MPa MPa g 25 0 4 0 7 16 M8 480 5 40...

Page 2: ...a...

Page 3: ...cm...

Page 4: ...mm2 Cv m a cm cm MPa cm ml sec cm...

Page 5: ...a 5 6 5 1 2 5 6 5 6 5 1...