- 11 -

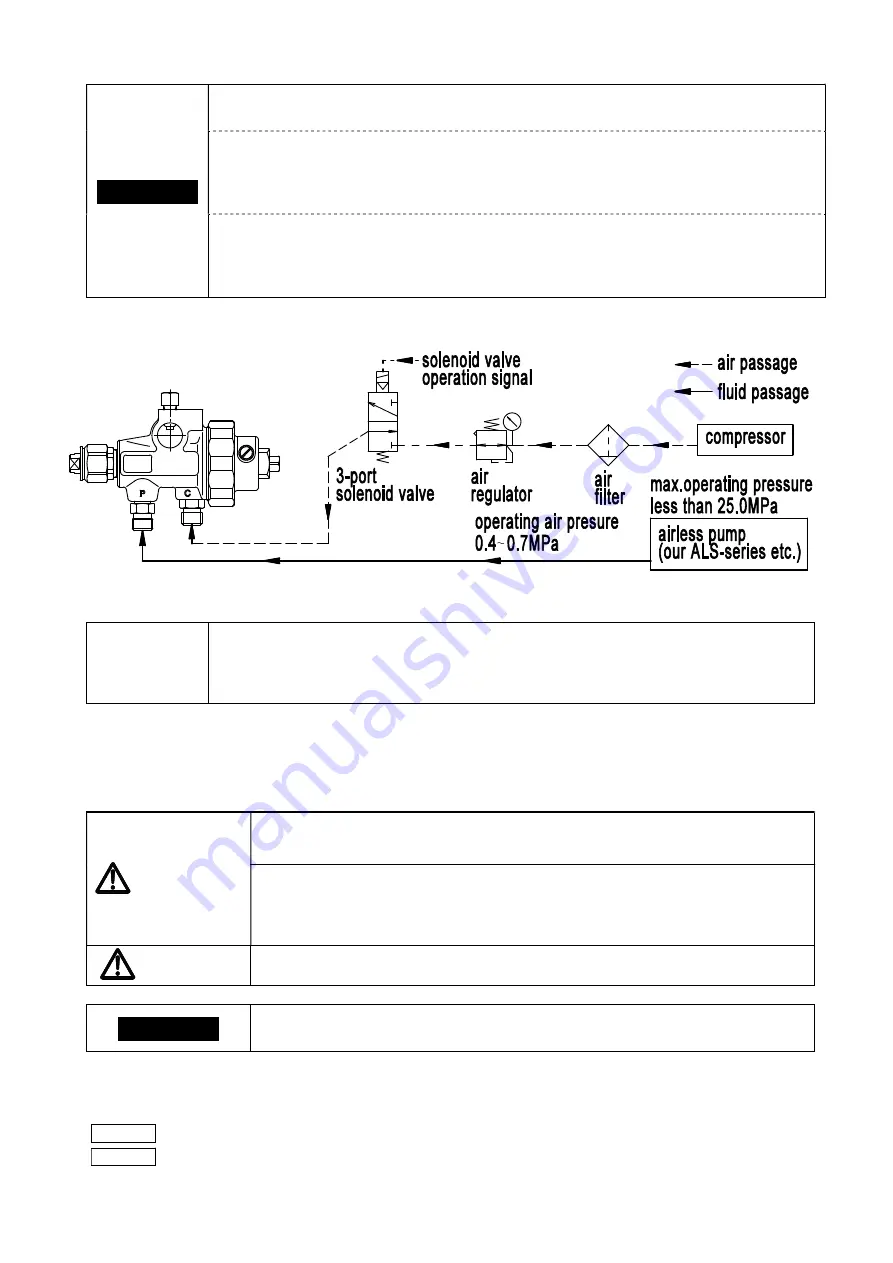

3-2 Operating circuit (refarence)

Important

Use clean operating air after it is filtered through air dryer and air filter.

Dirty piston or moisture in air can cause failure.

Use 3-port solenoid valve with effective area of more than 12.6mm

2

(equivalent to

φ

4mm Cv=0.7).

Small effective area can cause failure such as slow operation (slow start or

stop) of airless automatic spray gun.

Use operating air hose with less than

φ

6 inner dia. and less than 10m

length between 3-port solenoid valve and airless automatic gun.

Big or long air hose can cause failure such as slow operation (slow start or

stop) of airless spray gun.

Refer to operating circuit below.

3-3 Painting job

H I N T !

As fluid pressure increases, paint output increases. But on the other

hand, high pressure can be dangerous and precipitate corrosion of

equipment and nozzle tip. Adjust pressure as low as possible as far as

finish is satisfactory.

3-4 Cleaning and maintenance

Fully clean after job is finished in order to get longer lifetime and good performance at

next job.

During cleaning, be sure to wear protective cover such as glasses,

mask or gloves to avoid serious injury caused by paint or solvent

which might enter your eyes or you might inhale.

Be sure to stop pump, reduce fluid pressure down to 0 pressure and

stop operating air before you fit or remove nozzle tip.

Paint or solvent can be very dangerous when it enters human body

directly through eyes, mouth or skin.

Never use commercial or other parts instead of ANEST IW ATA

original spare parts.

Important

Do not immerse spray gun in solvent in order to clean it. If done, it

can cause piston packing, resulting in failure.

・

In order to get longer lifetime and good performance at the next job, fully clean it

according to the instructions below :

job 1

Remove nozzle tip from airless spray gun and clean it.

job 2

Clean paint passage of airless spray gun with clean cleaning liquid, which

is compatible with paint used.

WARNING

CAUTION

Summary of Contents for AL-96

Page 1: ...MPa MPa g 25 0 4 0 7 16 M8 480 5 40...

Page 2: ...a...

Page 3: ...cm...

Page 4: ...mm2 Cv m a cm cm MPa cm ml sec cm...

Page 5: ...a 5 6 5 1 2 5 6 5 6 5 1...