- 12 -

4. Selection of nozzle tip according to kind of paint

H I N T

!

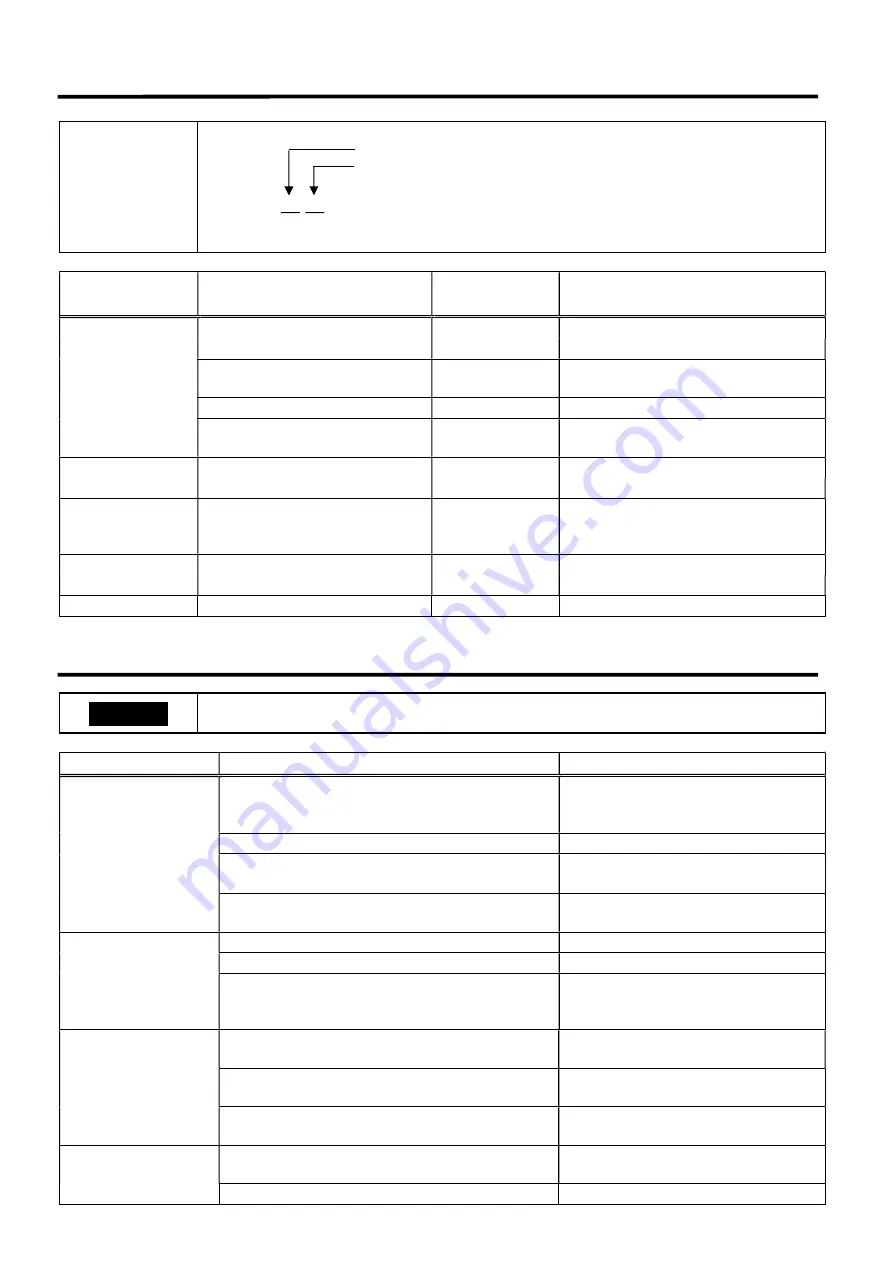

<Numbering system>

Pattern width 25 cm at 30cm spray distance.

Fluid output 0.7ml/sec/cm of width at fluid pressure

9.8MPa (0.98bar

/

14PSI).

NT-25 07

Use nozzle tip with large figures of last 2 digits when you spray paints of high

viscosity or easily clogged.

Usage

Kind of paint

Model

(NT-

□ □ □ □

)

Remarks

Shipbuilding

Rubber chloride paint,

2507-4009

Commonly used

Ship-bottom paint

Tar epoxy paint

3011-4013

Last two digits are large due to

high viscosity.

Zinc rich paint (organic)

2507-4009

Commonly used

Zinc rich paint (non-organic)

3019-4016

Last two digits are large because

it is easy to clog.

Construction W ater base (emulsion paint),

2505-4007

Commonly used

Ready mixed paint

Steel frame

Anti-corrosive paint

1507-2513

First two digits are small, and

last two digits are large, for

angle iron.

W oodwork

Clear lacquer,

1503-3005

Commonly used

Synthetic resin varnish

Common metal Lacquer, Melamine

1504-4007

Commonly used

5. Problems and remedies

Important

As for

☆

marked items, ask our distributor to remedy it for you. Incorrect

remedy cannot achieve satisfactory performance.

Problem

Cause

Remedies

Paint does not

come out.

Nozzle tip is clogged.

Clean nozzle tip and remove

foreign matter from hole by

needle.

Paint is not fed.

Inspect pump.

Operating air pressure is low.

Set it at 0.4

~

0.7 MPa.

(4

~

7bar/ ).

Filter in paint circuit is completely

clogged.

Clean or replace.

Paint comes out

Pump fluid pressure is low.

Increase pump fluid pressure.

weakly.

Filter in paint circuit is clogged.

Clean or fluid replace.

Nozzle tip is worn or number of nozzle tip

is too large. (Pump capacity is small

compared with nozzle tip being used.)

Replace with new tip or proper

sized tip.

Paint does not

stop smoothly.

(Paint leaks from

the gun tip.)

Pump paint pressure is too high.

Reduce paint pressure down to

25 MPa (255 kgf/cm

2

).

Paint sticks to needle packing [5-6].

Disassemble, clean or replace

parts.

☆

Seat between needle bar set [5-1] and

nozzle gland set [2] is worn.

Disassemble, clean or replace

parts.

☆

Paint leaks from

leak detection hole

of gun body.

W ear or damage of needle packing[5-6].

Adjust needle packing [5-6].

(Refer to item 6 on page 7.)

☆

W ear or damage of needle bar set[5-1]

Disassemble, clean or replace.

Summary of Contents for AL-96

Page 1: ...MPa MPa g 25 0 4 0 7 16 M8 480 5 40...

Page 2: ...a...

Page 3: ...cm...

Page 4: ...mm2 Cv m a cm cm MPa cm ml sec cm...

Page 5: ...a 5 6 5 1 2 5 6 5 6 5 1...