- 13 -

6. Adjustment of needle packing

Be sure to stop pump, reduce paint pressure down to 0 pressure and

stop operating air before you adjust needle packing

Important

Adjust needle packing in correct way. If not done, it can cause failure

such as slow gun operation (slow start and/or stop).

W hen leak does not stop even after you have adjusted needle packing, ask

the distributor who sold the gun to you for disassembly and inspection.

・

Paint can leak from leak detection hole of gun body due to wear of needle packing after

long periods of use.

・

If paint leaks, you can stop the leak temporarily with the following procedure.

But in that case, please disassemble and inspect immediately for protection of gun body

and other parts.

job 1

Stop operating air and reduce it down to 0 pressure.

job 2

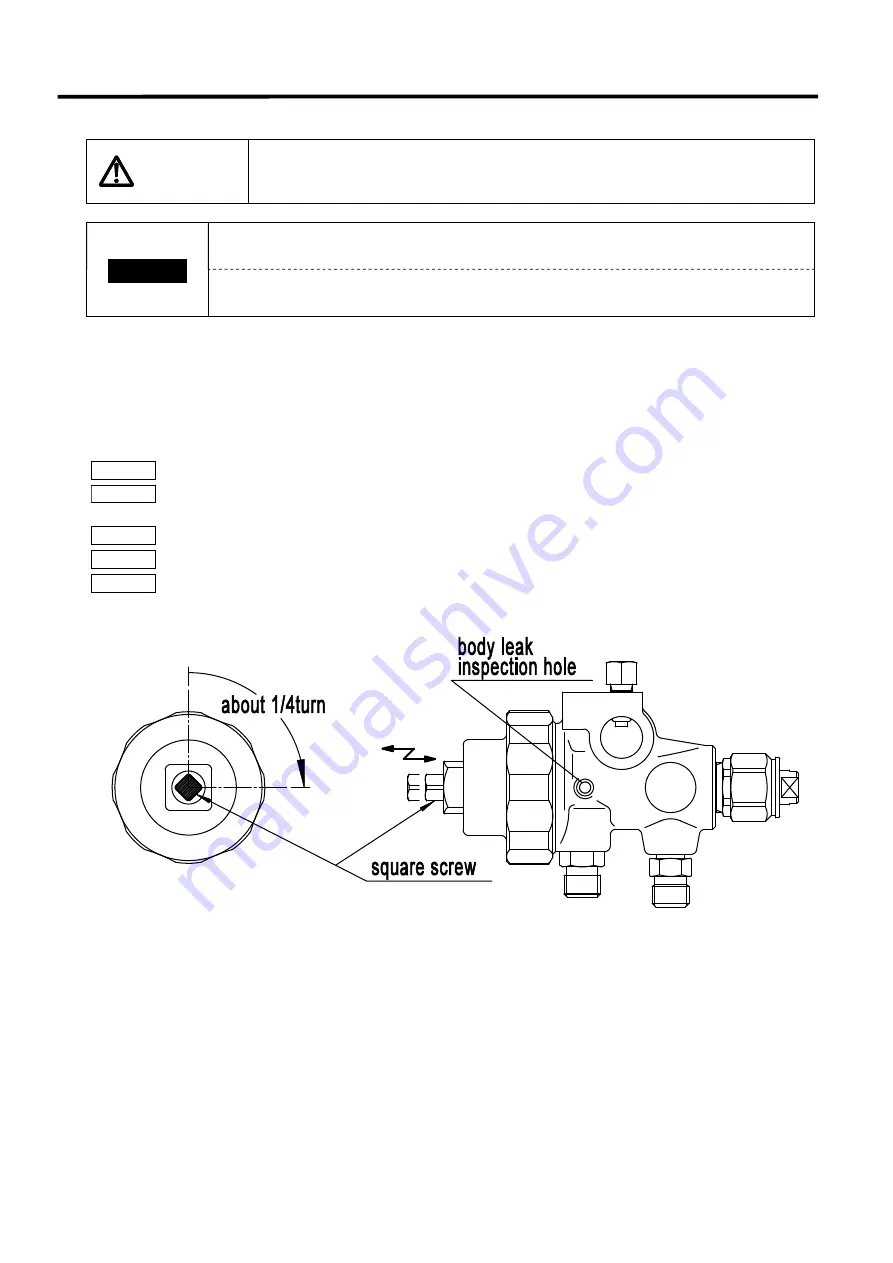

Turn square screw at the back of gun body about 1/4 turn clockwise to tighten

needle packing.

job 3

Check that paint does not leak from paint leak detection hole.

job 4

If leak still does not stop, turn the square locking crew another about 1/4 turn.

job 5

Supply operating air and check that square locking screw operates smoothly.

WARNING

Summary of Contents for AL-96

Page 1: ...MPa MPa g 25 0 4 0 7 16 M8 480 5 40...

Page 2: ...a...

Page 3: ...cm...

Page 4: ...mm2 Cv m a cm cm MPa cm ml sec cm...

Page 5: ...a 5 6 5 1 2 5 6 5 6 5 1...