- 9 -

Other precautions

1

.

Never alter this airless spray gun.

If done, it can cause insufficient performance and failure.

2

.

Enter working areas of other equipment (robots, reciprocators, etc.) after machines are turned off.

If not, contact with them can cause injury.

3

.

Never spray foods or chemicals through this gun.

If done, it can cause accident by corrosion of fluid passages or adversely affect health by mixed foreign matter.

4.

Securely connect fluid hose.

If hose is disconnected during operation, hazardous hose movement and paint ejection will cause severe bodily injury.

5

.

If something goes wrong, immediately stop operation and find the cause. Do not use again until you have solved the

problem.

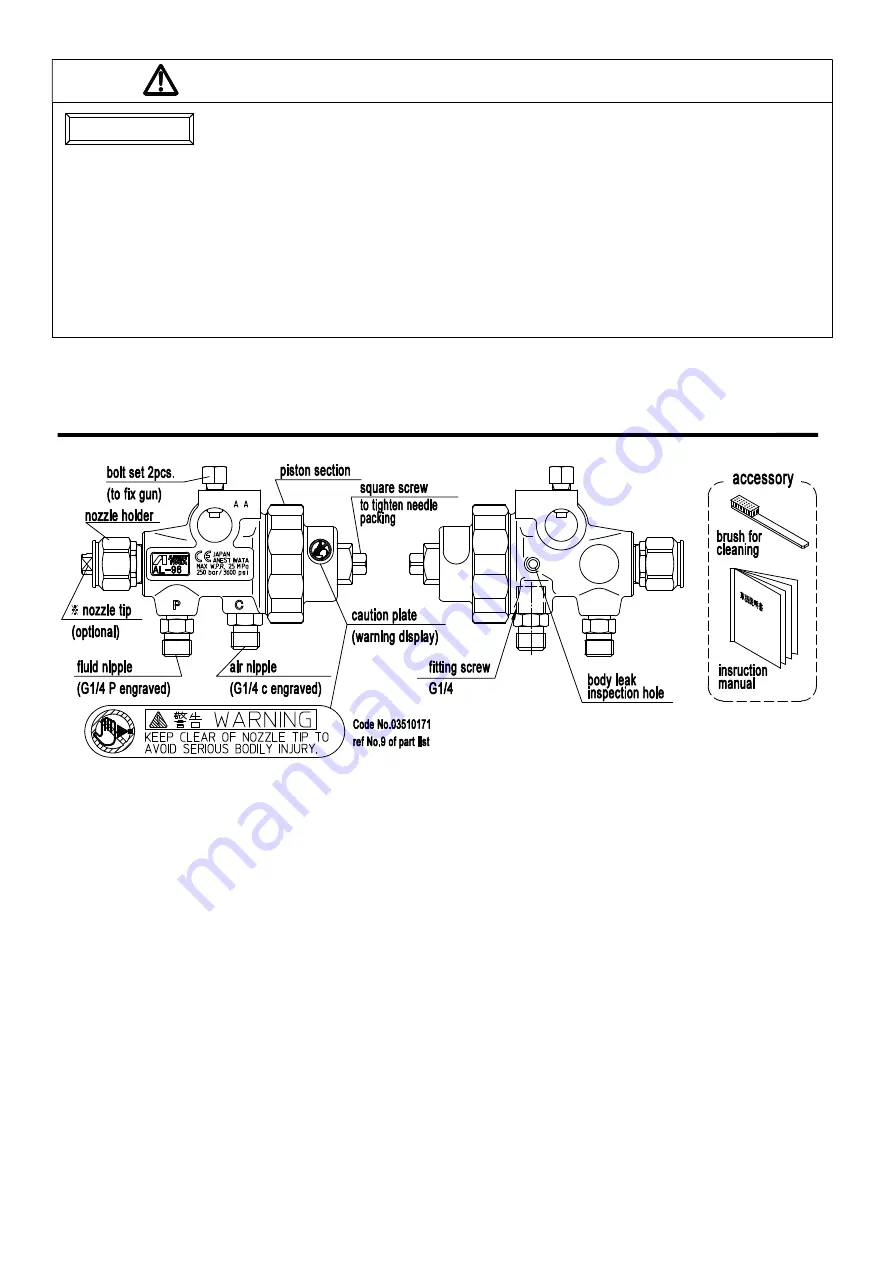

2. Name of components and checking the product

・

W hen you open the package, be sure to check that all goods are included and are in good

condition.

・

If there is any damage or missing components, do not use the product to avoid danger and

immediately contact the distributor who sold it to you.

・

Always keep caution plates (warning display) in good condition and clean.

If they are damaged or missing, replace with new ones.

WARNING

Summary of Contents for AL-96

Page 1: ...MPa MPa g 25 0 4 0 7 16 M8 480 5 40...

Page 2: ...a...

Page 3: ...cm...

Page 4: ...mm2 Cv m a cm cm MPa cm ml sec cm...

Page 5: ...a 5 6 5 1 2 5 6 5 6 5 1...