-7-

How to operate

Test operation1

①

First confirm that electric source switch of compressor is turned “ OFF ” , and

then insert electric cord into electric outlet.

②Turn on electric source switch “ ON ” and confirm that compressed air comes out.

・Operate for about 5 minutes under these conditions.・Check that there is no abnormal sound or vibration.

WARNING

・please plug electrical cord directly to the electric outlet.

※Use of extension cord will cause low amp draw and can cause motor to stall. Please refrain from using an extension cord.

~ Check automatic ON/OFF function ~

Connect air hose and air brush to air outlet, and turn electric source switch “ ON ” and check that it stops operation in a few seconds.

・After it stops, push button of airbrush to exhaust compressed air and check that it restarts operation.

Check that air does not leak from connection.

CAUTION

When compressed air does not come out of compressed air stops coming out soon even if it comes out, air regulator may be completely closed.

In that case. pull pressure adj. knob upwards till sound is heard and turn it clockwise to keep air regulator opened.

Operation

-------------------------------

① Confirm that electric source switch is turned “ OFF ” and insert electric source cord into electric outlet.

② Turn electric source switch “ ON ”.

③ Operation will start.

~Pressure adjustment~

Adjust exhaust pressure by both air regulator and pressure adj. knob. Pull pressure adj. knob upwards till clicking sound is heard and turn it clockwise

(pressure increases) or counterclockwise(pressure decreases). After adjustment, pull pressure adj. knob downwards till clicking sound is heard.

CAUTION

・Firmly attach coil hose and airbrush. If not, disconnected air hose can cause injury.

・Do not touch anything other than operating section during operation. If done, it can cause burns.

・If abnormal sound(clanking sound) or abnormal vibration occurs, immediately stop operation and remove abnormality and restart operation.

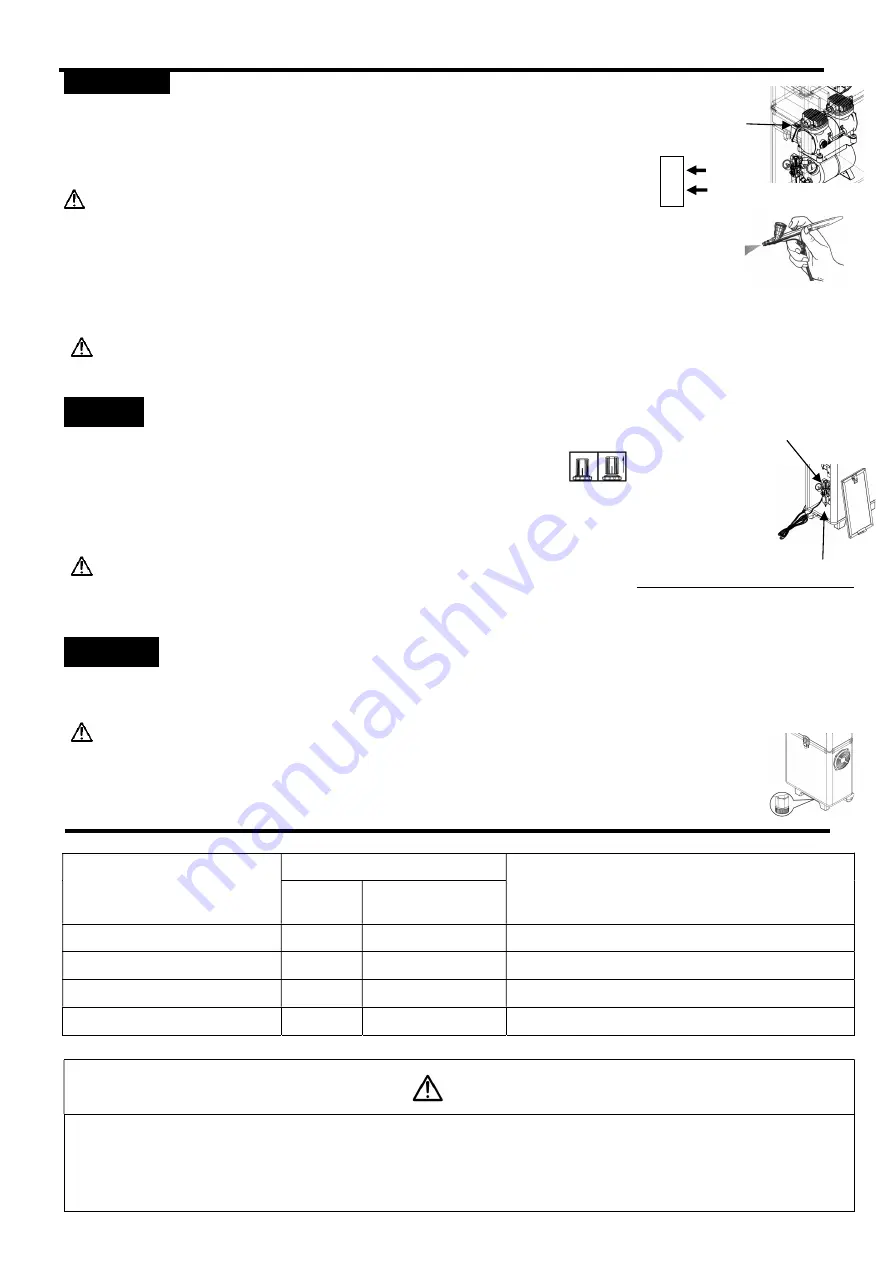

End of operation

After operation ends, turn electric source switch “ OFF ” and keep pushing button of air brush and completely exhaust compressed air

inside compressor. Push drain outlet of filter ball upwards from the bottom and completely exhaust compressed air and drain.

CAUTION

When exhausting air, exhaust air away from humans.

※may cause skin irritation.

Maintenance and inspection

Do the following items periodically to use compressor in the best condition.

Inspection items

Maintenance time

Contents

Daily

every 100hours or

every 6 months

Check operation

○

Refer to 3.How to operate(page3)

○

Refer to 3.How to operate(page 3)

Abnormal sound or vibration

○

Refer to 5.Problems and remedies(page 4)

Intake filter

○

Clean filter by blowing air.

■ Precautions about disassembly

WARNING

Be sure to turn off main electric source by pulling out electric source cord from electric outlet before doing maintenance and inspection.

※If not, sudden operation can cause injury.

Completely exhaust compressed air inside compressor before doing maintenance and inspection.

※If not, flying parts can cause injury during disassembly.

Push button to exhaust

compressed air

ON/OFF Switch

○

I

ON

OFF

Drain valve (airtank)

It is attached in bottom of compressor

Drain regularly by drain valve.

Pull upwards till clicking sound is heard and turn

clockwise.

Drain regularly by

pushing up the pin

。

air regulator+

Pressure adj. knob