-8-

Test operation1

①First check that electric source switch of compressor is turned “ OFF ” , and

Then insert electric cord into electric outlet.

②Turn on electric source switch “ON” and check that compressed air comes out.

・Operate for about 5 minutes under these conditions.

・Check that there is no abnormal sound or vibration.

WARNING

・please plug electrical cord directly to the electric outlet.

※Use of extension cord will cause low amp draw and can cause motor to stall.

Please refrain from using an extension cord.

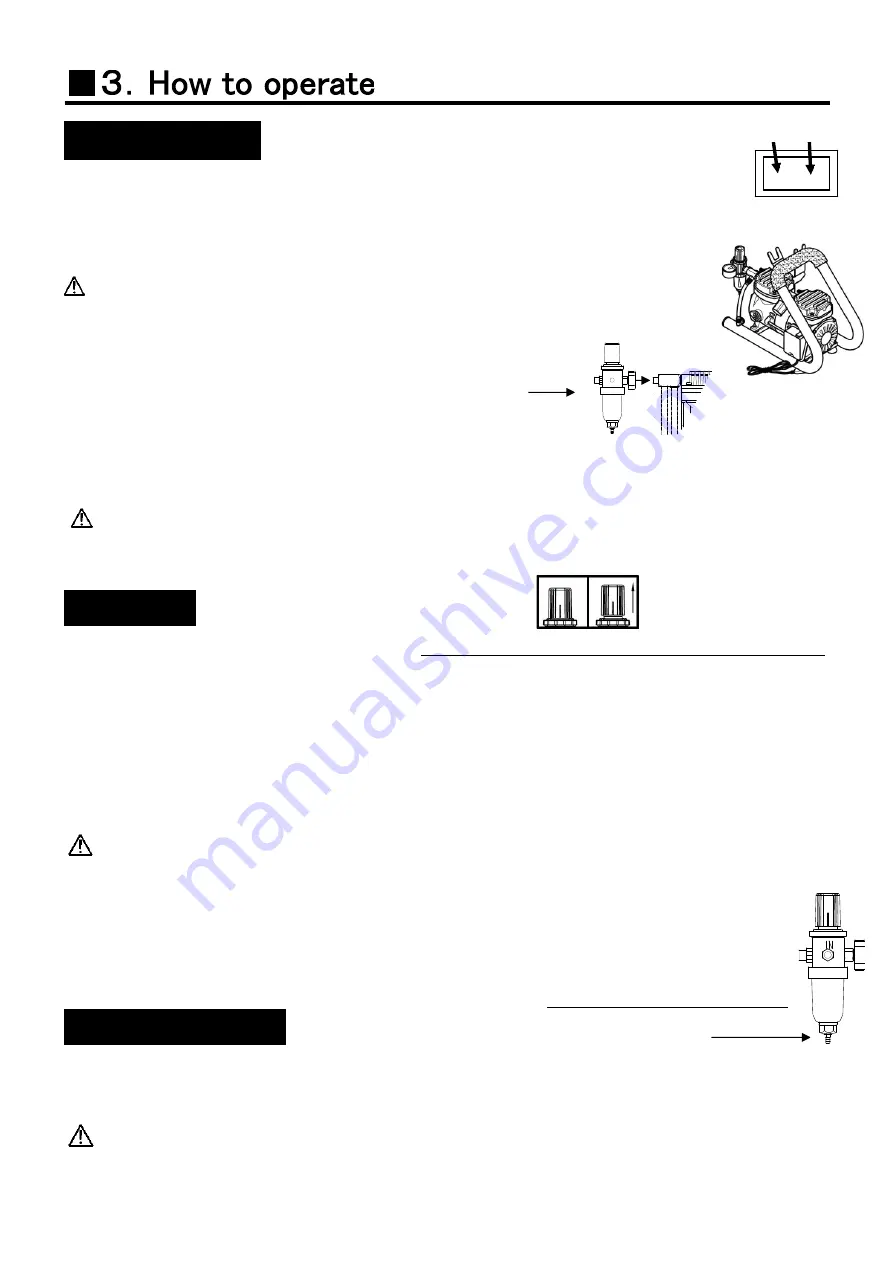

~Connection~

①Attach regulator/filter assembly to the compressor unit.

②

Connect air hose.

③Check automatic ON/OFF function.

Connect air hose and air brush to air outlet, and turn electric source switch “ ON ” and check that it stops operation in a few seconds.

・After it stops, push button of airbrush to exhaust compressed air and check that it restarts operation.

Check that air does not leak from connection.

CAUTION

When compressed air does not come out of the air compressor or air stops coming out shortly after, then air

regulator may be completely closed. In that case, pull pressure adj. knob upwards till sound is heard and turn it

clockwise to keep air regulator opened.

Operation

①Connect air hose and airbrush to compressor.

Pull up (for adjusting) or push down until click sound.

②Check that electric source switch is turned “OFF”and insert electric source cord into electric outlet.

③Turn electric source switch “ ON ”.

④Operation will start.

~How to adjust pressure~

Adjust exhaust pressure by both air regulator and pressure adj. knob. Pull pressure adj.

knob upwards until clicking sound is heard and turn it clockwise(pressure increases)or

counterclockwise(pressure decreases). After adjustment, push pressure adj. knob downwards

until clicking sound is heard.

CAUTION

・

Firmly attach compressor~air hose~airbrush If not firmly attached, air hose may disconnect and this

can cause injury.

When adjusting exhaust pressure, do not place your hands near or around air regulator or pressure

adj. knob. If done, it can entangle your hands and cause injury.

・Do not touch anything other than operating section during operation. If done, it can cause burn.

・If abnormal sound(clanking sound) or abnormal vibration occurs, immediately stop operation

and solve problem before restart operation.

Drain regularly by pushing up the pin

End of operation

After operation ends, turn electric source switch “ OFF ”and keep pushing button of air brush and completely

exhaust compressed air inside compressor. Push drain outlet of filter ball upwards from the bottom and completely

exhaust compressed air and drain.

CAUTION

・Prepare cup or something to receive drainage when exhausting drain.

・If not, drainage can scatter and cause injury or stain surrounding area.

Electric source switch

○

一

OFF

ON

Summary of Contents for IS875HT

Page 2: ......

Page 5: ...1 ON OFF...

Page 7: ...1 OFF AC100 ON ON OFF ON...

Page 9: ...100h 8 8 8 12 6...

Page 11: ...15 40...