- 4 -

■

Parts list

When ordering parts, specify gun’s model, part name with ref. No. and

marked No. of air cap set, fluid nozzle and fluid needle.

When replacing fluid nozzle or/and fluid needle for pressure feed

application, please order nozzle needle set.

■

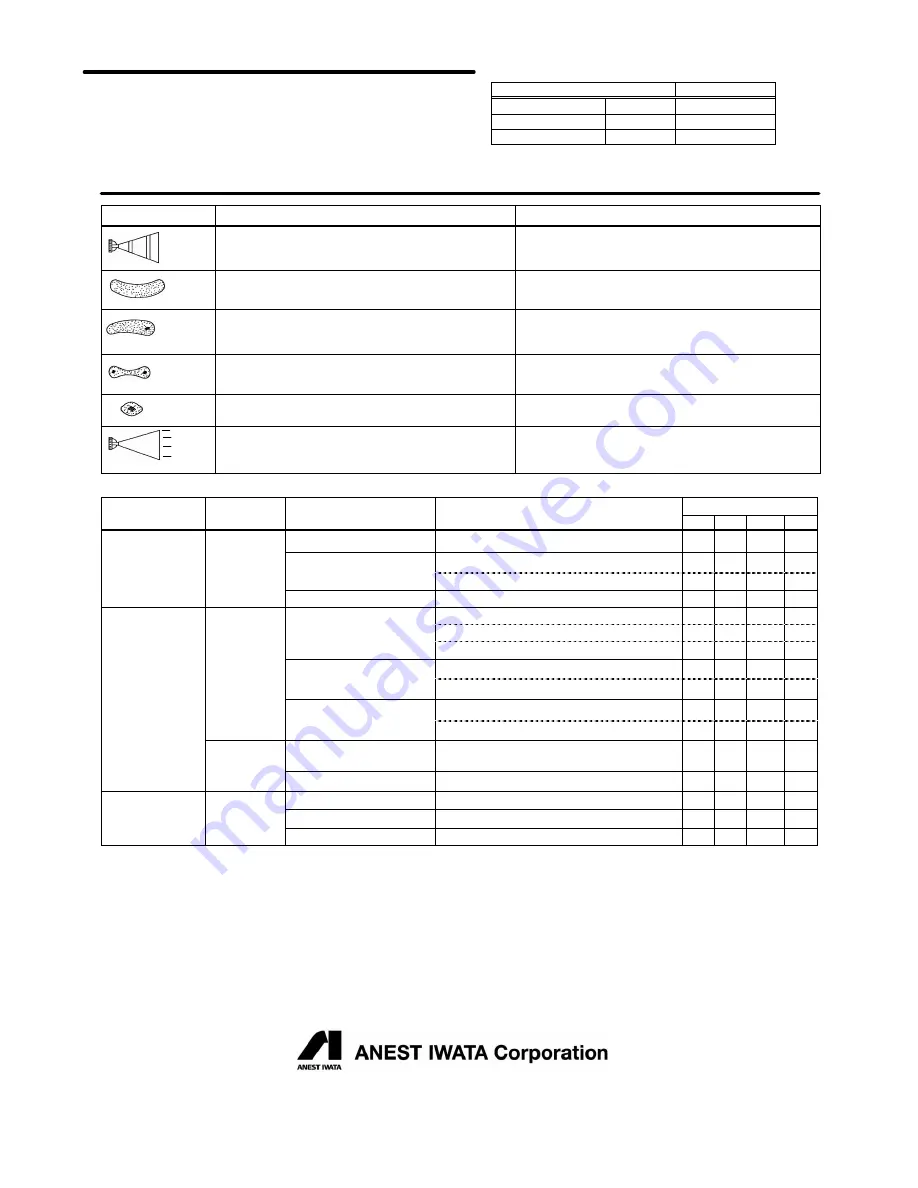

Troubleshooting

Spray Pattern

Problems

Remedies

Fluttering

1. Air enters between fluid nozzle and tapered seat of gun body.

2. Air is drawn from fluid needle packing set..

3.Air enters at fluid container fitting nut or fluid hose joint.

1. Remove fluid nozzle to clean seat.

I

f it is damaged, replace nozzle.

2. Tighten fluid needle packing.

3. Fully tighten joint section.

Crescent

1. Paint buildup on air cap partially clogs horn holes.

Air pressure from both horns differs.

1.

Remove obstructions from horn holes with attached brush.

But do not use metal objects to clean horn holes.

I

nclined

1. Paint buildup or damage on fluid nozzle circumference and air cap

center.

2. Fluid nozzle is not properly fitted.

1. Remove obstructions.

Replace if damaged.

2. Remove fluid nozzle and clean seat section.

Split

1. Paint viscosity too low.

2. Fluid output too high.

1. Add paint to increase viscosity.

2.

Tighten fluid adj. knob to reduce fluid output.

Or turn pattern adj. valve set clockwise.

Heavy Center

1. Paint viscosity is too high.

2. Fluid output is too low.

1.

Add thinner to reduce viscosity.

2.Turn fluid adj. valve knob counter-clockwise to increase fluid output.

Spit

1. Fluid nozzle and fluid needle set are not seated properly.

2.The first-stage travel of trigger

(when only air discharges) decreases.

3. Paint buildup inside air cap set.

1.

Clean or replace fluid nozzle and fluid needle set.

2.

Replace fluid nozzle and fluid needle set.

3. Clean air cap set.

R1

:

retighten R2

:

adjust R3 :

clean R4 : replace parts

Remedy

Problem

Where it

occurred

Parts to be checked

Cause

R1

R2

R3

R4

Air valve

* Dirt or damage on seat

○

○

* Dirt or damage on seat

○

○

Air valve seat set

* Wear on air valve spring

○

Air leaks

(from tip of air cup)

Air

valve set

O ring

* Damage or deteriorated

○

* Dirt, damage, wear on seat

○

○

* Loose fluid needle adj. knob

○

Fluid nozzle

〜

fluid needle set

* Wear on needle spring

○

* Insufficient tightening

○

Fluid nozzle

〜

gun body

* Dirt or damage on seat

○

○

* Needle does not return due to packing set too tight

○

○

Fluid nozzle

Fluid needle

〜

packing set

* Needle does not return due to paint buildup on fluid needle

○

○

Needle packing set

〜

needle set

* Wear

○

○

Paint leaks

Fluid needle

Packing seat

* Insufficient tightening

○

Fluid adj. knob

* Insufficient opening

○

Tip hole of nozzle

* Clogged

○

Paint does not

come out

Tip of gun

Paint filter

* Clogged

○

○

Fluid nozzle-fluid needle set combination

Fluid nozzle

Fluid needle set

Orifice

φ

mm(in)

Mark

Mark

φ

1.0 (0.039)

W101/T10

10008

φ

1.3 (0.051)

W101/13

10013

Manual No.T033-05

Code No.03741612

3176, Shinyoshida-cho, Kohoku-Ku,

Yokohama 223-8501, Japan