3

6

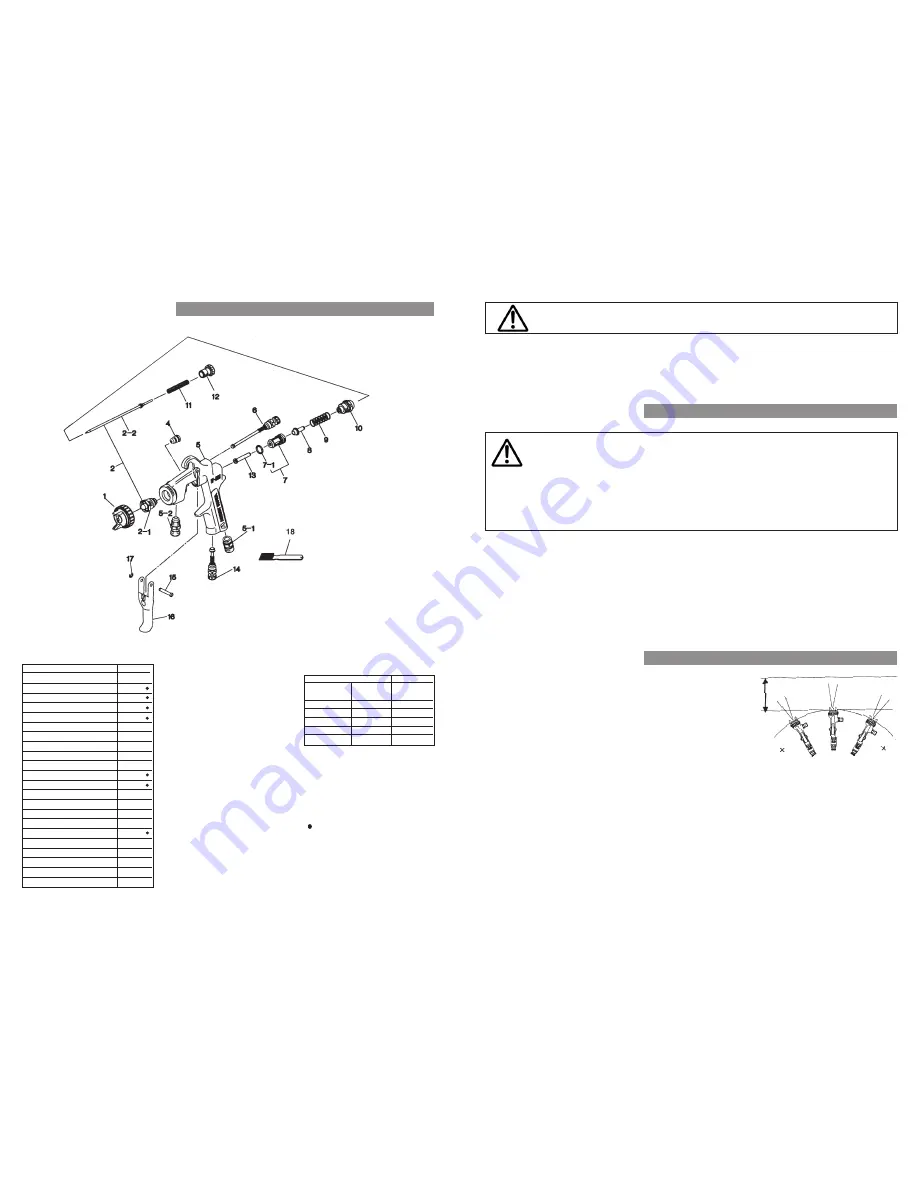

SPARE PARTS LIST

Fluid nozzle

Fluid needle

Orifice

Mark

set -Mark

mm(in)

0.8 (0.031)

200WB/08

40012

1.0 (0.039)

200WB/10

40012

1.2 (0.047)

200WB/12

40012

1.6 (0.063)

400WB/16

20015

1.8 (0.071)

400WB/18

20020

Marked parts are wearable parts.

NOTE:

When ordering parts, specify gun’s

model, part name with ref. No. and marked

No. of air cap set, fluid nozzle and fluid nee-

dle.When replacing fluid nozzle or/and fluid

needle for pressure feed application, please

order nozzle needle set.

DESCRIPTION

REF.PART

A I R C A P S E T

1

N O Z Z L E + N E E D L E S E T

2

F L U I D N O Z Z L E

2 - 1

F L U I D N E E D L E S E T

2 - 2

NEEDLE PACKING CARTRIDGE

4

B O D Y S E T

5

A I R N I P P L E

5 - 1

F L U I D N I P P L E

5 - 2

PAT T E R N A D J . S E T

6

A I R VA LV E S E AT S E T

7

O R I N G

7 - 1

A I R VA LV E

8

A I R VA LV E S P R I N G

9

F L U I D A D J . G U I D E

1 0

F L U I D N E E D L E S P R I N G

11

F L U I D A D J . K N O B

1 2

A I R VA LV E S H A F T

1 3

A I R A D J . S E T

1 4

T R I G G E R S T U D

1 5

T R I G G E R

1 6

E S T O P P E R

1 7

B R U S H

1 8

FLUID NOZZLE-FLUID NEEDLE SET

COMBINATION

PARTS LIST

3. Never spray foods or chemicals through this gun.

If done, it can cause accident by corrosion of fluid passages or adversely affect health by mixed foreign matter.

4. If something goes wrong, immediately stop operation and find the cause. Do not use again until you have solved the

problem.

HOW TO CONNECT

1. Connect an air hose to air nipple tightly.

2. Connect a fluid hose or a container to fluid nipple tightly.

3. Flush the gun fluid passage with a compatible solvent.

4. Pour paint into container, test spray and adjust fluid output as well as pattern width.

HOW TO OPERATE

Suggested air pressure is 1.0 to 2.0 bar (14 to 29 PSI)

Recommended paint viscosity differs according to paint property

and painting conditions. 15 to 23 sec. / Ford cup #4 is recommendable.

Keep fluid output as small as possible to the extent that the job will

not be hindered. It will lead to better finishing with fine atomization.

Set the spray distance from the gun to the work piece as near as

possible within the range of 100_250 mm (3.9_9.8 in).

The gun should be held so that it is perpendicular to the surface of the workpiece at all times. Then, the gun should move in a straight

and horizontal line. Arcing the gun causes uneven painting.

CAUTION

- Use clean air filtered through air dryer and air filter. If not, dirty air can cause painting failure.

- When you use this gun for the first time after purchasing, clean fluid passages spraying thin-

ner and remove rust preventive oil.

If not, remaining preventive oil can cause painting failure such as fish eyes.

- Firmly fix hose or container to spray gun. If not, disconnection of hose and drop of container

can cause bodily injury.

OTHER PRECAUTIONS

100-250 mm

3.9-9.8 in