7

G

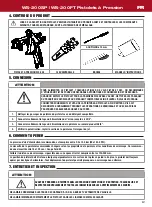

Reassemble air valve (9), air valve spring (10) and fluid adj. guide

set (11) together. Next insert fluid needle set (2-2) into fluid adj.

guide set (11) fit it into gun body set and tighten fluid adj. guide

set (11) by using the enclosed spanner.

IMPORTANT! If you try

to fit air valve spring (10) and air valve (9) into gun body,

without fluid needle set (2-2) assembled, air valve will not

be fitted correctly and the packing of fluid adj. guide set (11)

will be damaged.

H

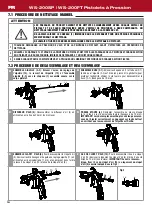

TRIGGER SET (16):

To disassemble trigger set (16), unscrew hex-

agon socket buttom bolt (18) by using hex. 2.5 mm allen wrench

(not included) and remove trigger stud (17).

IMPORTANT! To reassemble, fit the hexagonal shape of the

edge of the trigger stud (17) into hexagonal hole of it, see fig.2.

I

PATTERN ADJ. SET (7) and

AIR ADJ. SET (15) . IMPORTANT:

Before disassembling or assembling of pattern adj. set (7) and/or air adj. set

(15) make sure that these operations will be carried out with the adjustments fully opened. Otherwise it could cause damage of seats section.

Disassemble pattern adj. set (7) and/or air adj. set (15) by using the enclosed spanner hex. 13 mm size.

9 10 11 2-2

17

18

17

16

Fig. 2

8. PROBLEMS CAUSES AND REMEDIES

PROBLEM

CAUSE

REMEDY

SPRAY GUN

DOES NOT SPRAY

Fluid adj. knob (13) closed.

Check and adjust it.

Tip hole of nozzle obstructed.

Check and clean it.

INTERMITTENT

SPRAY PATTERN

Air escapes from fluid nozzle (2-1).

Check , clean & replace if necessary.

Air escapes from fluid needle packing (6).

Tighten.

Dirty inside air cap set (1).

Clean.

DEFECTIVE

SPRAY PATTERN

Dirty nozzle (2-1) or air cap set (1).

Clean carefully.

Nozzle (2-1); air cap (1) or baffle ring (4) has been

damaged.

Replace if damaged.

Fluid nozzle (2-1) or baffle ring (4) are loose.

Tighten.

Paint viscosity too high or too low.

Dilute paint or increase viscosity.

Fluid output too high or too low.

Adjust fluid adj. knob (13) to reduce

or increase.

LEAKING

Fluid nozzle (2-1), needle set (2-2) or gun body (5),

dirty, damaged or worn on seat.

Clean & replace if necessary.

Dirt inside air cap set (1).

Clean.

Loose fluid adj. knob (13).

Adjust.

Fluid needle spring set (12) is worn.

Replace.

Loose fluid nozzle set (2-1).

Tighten.

Needle packing set (6) dirty or worn.

Clean or replace.

AIR ESCAPES FROM AIR CAP

Air valve (9), air valve seat (8) or air valve spring

(10) dirty or damaged.

Clean or replace if necessary.

Air valve seat set "O"ring (8-1) damaged or worn.

Replace.

EN

WS-200SP | WS-200FT Pressure Spray Guns

Summary of Contents for WS-200 FT

Page 51: ...51 Comments ...