12

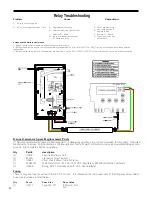

RELAY 1 "TIME"

SET

TRIGGER

STEP 8S

STeP 8 S

– Set relay to activate by Time, Gallons, regen Gallons, lockout, Off or Ser-

vice alarm

by using

or

buttons. A relay can be used to operate a chemical feed pump

or solenoid, etc. The choices are:

•

relay Triggered on Time

‑

Relay activates after set number of minutes after start of

regen

-

eration.

Start of regeneration is defined by first backwash cycle, dn brine or up brine,

whichever is first. Relay deactivates after set time. Press NEXT for programming.

•

relay Triggered on Gallons

‑

Relay activates every set number of gallons while

in

service and deactivates after set time. Press NEXT to go to 12S for programming.

•

relay Triggered on regen Gallons

‑

Relay activates after set number of gallons in

service

or

gallons used during regeneration and de

‑

activates after set time or when meter

stops

registering flow, whichever comes first. Press NEXT to go to

15S

for programming.

•

Service alarm

‑

Relay activates on service alarm setting: gallons, time or both, see

step

17S.

•

relay Triggered for lockout

- Relay closes at set number of minutes before or after

start of regeneration. Start of regeneration is referenced by 1st backwash or draw

mode. Negative start time delays regeneration by that amount. Relay remains active

during error, after power loss and after manual advance. Selection of energizing relay

for complete regeneration cycle is available by selecting REGEN for time setting, see

step 18S.

•

Off

‑

If off is selected, Steps 8S to 20S will not be shown.

Factory setting =

OFF

.

Press NEXT to go to step 21S or other selection screens for relay settings.

RELAY 1 SET POINT

STEP 9S

STEP 9 S

–

If off was selected in previous step, this screen does not appear.

If Time chosen to activate relay,

use up and down arrows to set # of minutes

SET

19:00

MIN

AFTER START OF REGEN to activate relay. Start of regeneration is defined

as first Backwash or Regenerant Draw mode. Time Range = 1 – 500 minutes.

Press

NEXT to go to Step 10S.

RELAY 1 DURATION

11:00

MIN

STEP 10S

STEP 10 S

–

Use Up and Down arrows to set duration of relay activation in

minutes. Time Range is 0:01 (1 second) to 500:00 (500 minutes) Press NEXT to

go to Step

21S. Press REGEN to return to previous step.

SET

RELAY 1 "GALLONS"

STEP 11S

STEP 11 S

– Gallons chosen to activate relay.

If Off or Time was selected in previous

steps, this screen does not appear. Press NEXT for trigger programming.

SET

TRIGGER

RELAY 1 SETPOINT

SET

1.0

GAL

STEP 12S

STeP 12S

–

Use up and down arrows to select number of gallons per relay

activation of regen gallon setting. Range = 0.1

‑

100 gallons.

Press NEXT to go to

Step 13S.

Press REGEN to return to previous step.

RELAY 1 DURATION

SET

0:01

MIN

STEP 13S

STEP 13 S

–

Use up and down arrows to set duration of relay activation in

minutes. Range = 0:01 (1 second)

‑

500:00 (500 minutes). Press NEXT to go

to Step 21S. Press REGEN to return to previous step.

RELAY 1 TRIGGER

SET

REGEN

GAL

STEP 14S

STEP 14 S

– If REGEN gallons chosen to activate relay.

Relay activates after set number of

gallons have been used in service

or

during regeneration and then deactivates after set period

of time or after flow stops, whichever comes first. Meter reads during regeneration. Press

Summary of Contents for PurAzone A03

Page 1: ...PurAzone A03 Filtration PurAzone A03 Filtration Filter Manual Owner s Filter Manual 2013 2014...

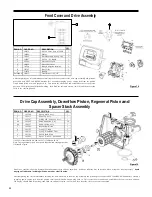

Page 5: ...5 Figure 2 Figure 4...

Page 14: ...13 NEXT to go to Step 15S...

Page 18: ...17 RETURN TO NORMAL MODE...

Page 20: ...16 NEXT to go to Step 10CS...

Page 34: ...28...