-

I

II

-

CT

39

60

33

00

.fm

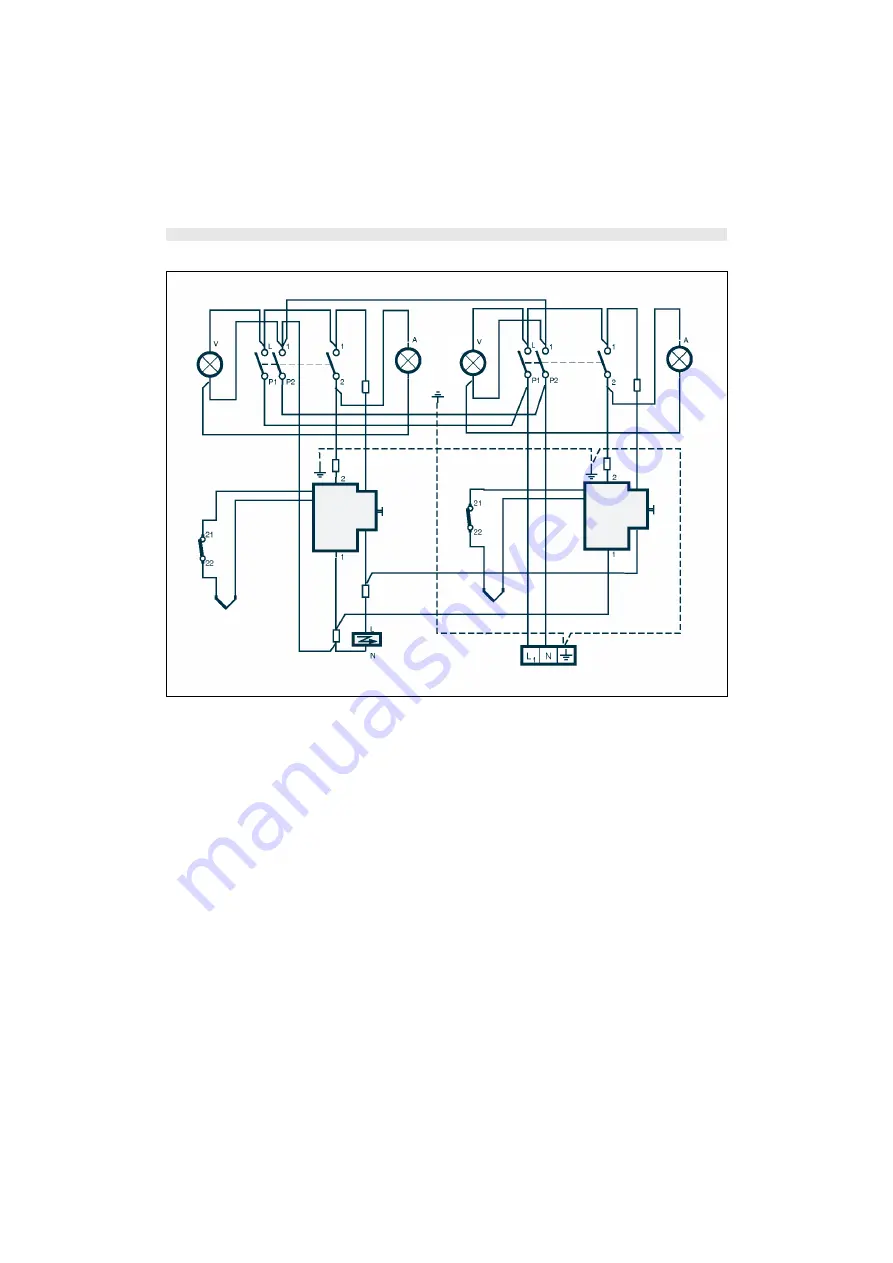

ELECTRIC DIAGRAM

1)

Terminal block

2)

Switch with coaxial thermostat -LH fryer

3)

Mains power indicator light -LH fryer

4)

Thermostat indicator light -LH fryer

5)

Gas solenoid valve with ignition contact - LH fryer

6)

Electronic ignition device

7)

Safety thermostat-LH fryer

8)

Thermocouple - LH fryer

9)

Switch with coaxial thermostat - RH fryer

10)

Mains power indicator light - RH fryer

11)

Thermostat indicator light -RH fryer

12)

Gas solenoid valve with ignition contact - RH fryer

13)

Safety thermostat - RH fryer

14)

Thermocouple - RH fryer

IDM-39603312600.tif

1

6

8

7

5

14

13

10

11

4

9

3

2

12