ANGELUS SANITARY CAN MACHINE COMPANY

SERVICE NOTICE

2 of 3

6/16/95-18033003

Motor Installation

A.

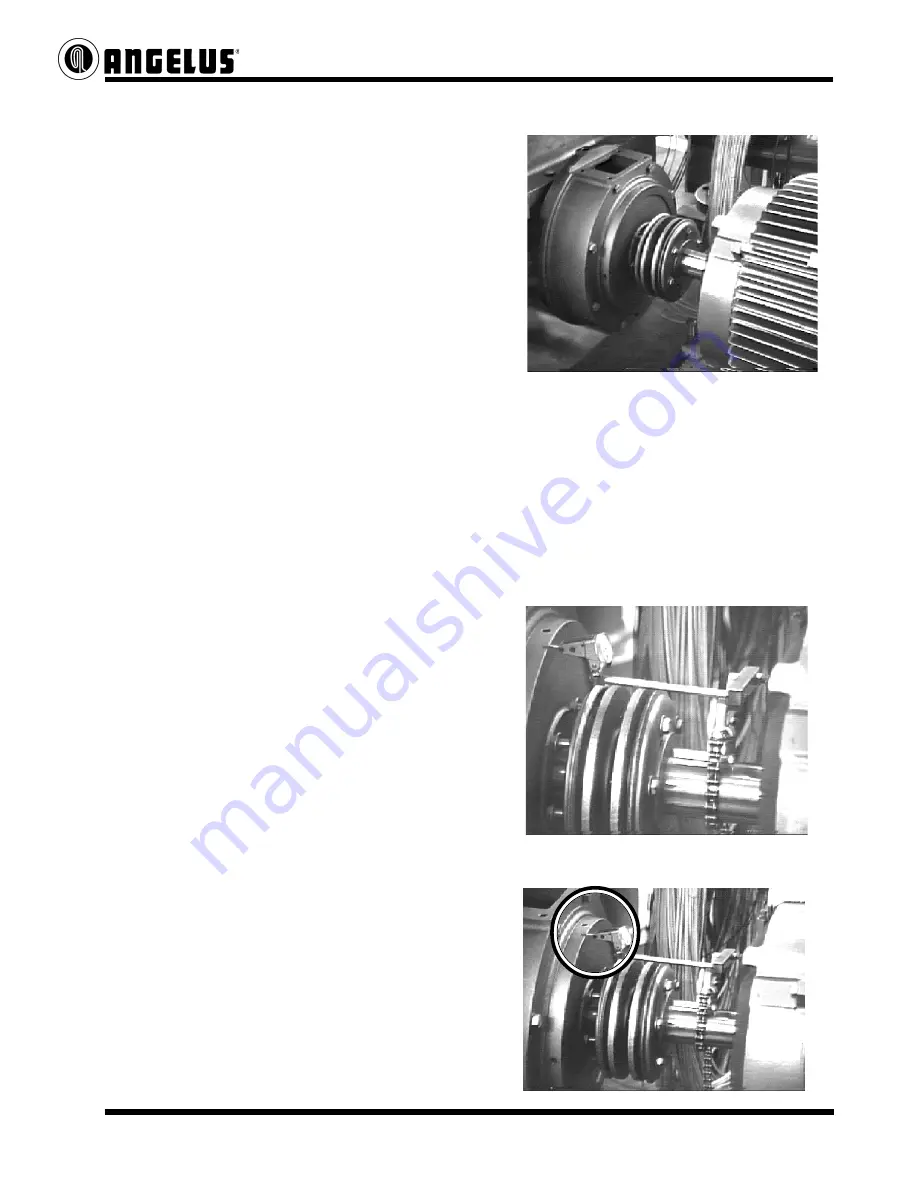

Install the Motor. Motor installation

should bring the Motor Shaft and Main

Drive Shaft within 1/4 inch of alignment.

Motor frames will vary, therefore, spacers

may have to be added under the Motor frame.

Center the Motor mounting holes with the

screws to provide room for angular

alignment later.

NOTE:

It is not suggested to use thin Shim Stock

to make this alignment. There is enough

Leaving 5/8 of an inch between the

allowable movement in the Sub-Base

Motor Shaft and Main Drive Shaft

slotted holes and Support Pad screws to

allows room for Coupling installation.

"zero" this in.

There should be approximately 5/8 of an

inch between the end of the Motor shaft

and the Main Drive Shaft for Coupling

installation or removal.

Dial Indicator Setup & Adjustment Parameters

Parts Required;

Dial Indicator with needle or plunger

Strap Clamp or Magnetic Base Mount

A.

Attach a dial indicator and strap clamp

(a magnetic base can be used if a strap

clamp is not available) to the Motor Shaft.

Align the dial to first get a reading around

the outer perimeter of the Brake Housing

machined surface.

Dial set for the Perimeter Reading.

B.

Use jack screws and Pad screws to bring

vertical and side to side alignment between

the Motor Shaft and Brake Housing

within .005 of an inch. This is the Perimeter

alignment.