15

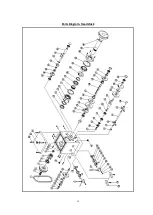

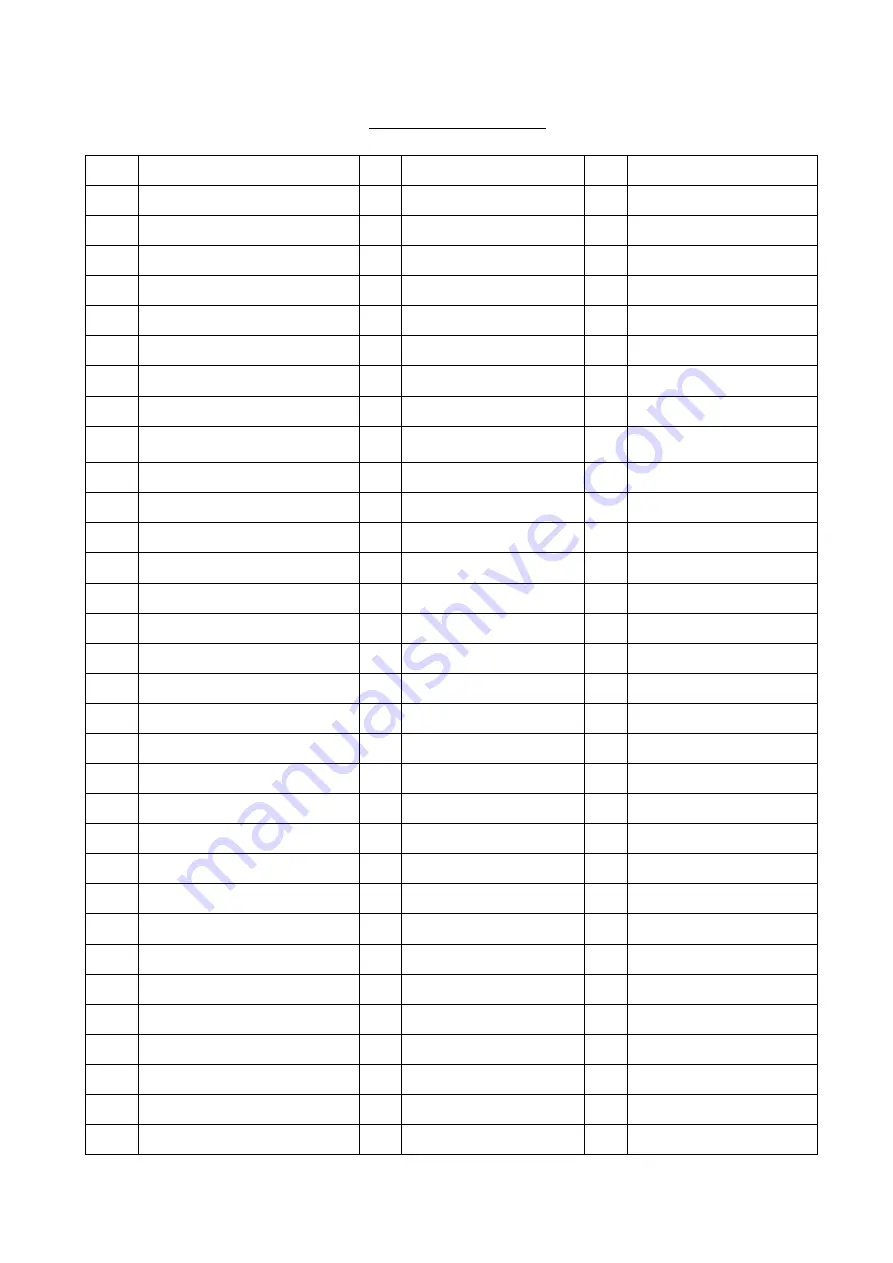

Parts Listing- Headstock

NO.

Description

1

V-belt type 700

35

Screw

67

C-Clip

2

Spanner nut

36

Localing sleeve

68

Middle shaft

3

Lock washer for circular nut

37

Washer

69

Thin flat key

4

Spindle pulley

38

O-seal ring

70

Gear

5

Taper roller bearing

39

Right Block

71

Gear

6

Hexagon socket head screw

40

Oil Sight

72

C-Clip

7

Pulley seat

41

Sleeve

73

Spanner nut

8

Felt cover

42

C-Clip

74

Lock washer for circular nut

9

Crossrecessed pan head screws

43

Left shifting fork

75

Hexagon socket head

screw

10

Plain washers

44

Shifting fork shaft

76

Sleeve

11

Lathe head

45

Right shifting fork

77

Pressurize washer

12-14 /

46

Sleeve

78

Sleeve spacer

15

Oil drain plug

47

Nut

79

Taper roller bearing

16

Oil cup

48

Plain washers

80

C-Clip

17

C-Clip

49

Gear

81

Gear

18

Cover

50

Felt cover

82

Taper roller bearing

19

Change Gear

51

Sleeve

83

Pressurize washer

20

Sleeve spacer

52

Taper roller bearing

84

Main shaft bearing oil seal

21

Plain parallel key

53

Plain parallel key

85

Lathe spindle

22

Sleeve

54

Output shaft

86

Plain parallel key

23

Gear

55

Plain parallel key

87

Sleeve spacer

24

Shaft

56

Gear

88

Gear

25

Screw

57

Gear

89

Gear

26

Left Block

58

Gear

90

Sleeve spacer

27

Handle lever

59

Sleeve spacer

91

Gear

28

Chock

60

Sleeve

92

Plain parallel key

29

Screw

61

Sleeve spacer

93

Plain parallel key

30

Set screws with cone point

62

Plain parallel key

94

Single shaft

31

Spring

63

Gear

95

Hexagon screw

32

Steel ball

64

Gear

96

Oil port plug

33

Handle seat

65

Gear

97

Transmission cover

34

Taper pins

66

C-Clip

Summary of Contents for BL330E

Page 1: ......

Page 10: ...10 ...

Page 14: ...14 Parts Diagram Headstock ...

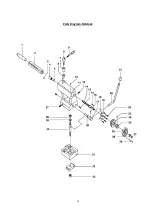

Page 16: ...16 Parts Diagram Trestle ...

Page 18: ...18 Parts Diagram Bed ...

Page 20: ...20 Parts Diagram Apron ...

Page 22: ...22 Parts Diagram Tailstock ...